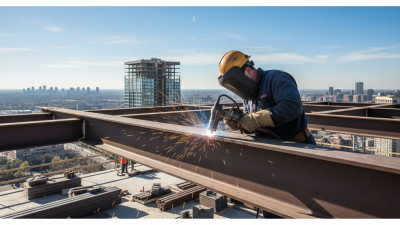

In industrial manufacturing, Weld Studs play a crucial role. These fasteners provide strong and reliable connections in various applications. John Smith, a recognized expert in welding technology, emphasizes, "Weld Studs are the backbone of efficient assembly processes."

Weld Studs are used in automotive, construction, and other sectors. They simplify the joining of materials, ensuring durability. However, improper use can lead to weaknesses in the assembly. Many engineers overlook the significance of correct installation techniques.

The market for Weld Studs continues to grow. Innovations are shaping their production and application. As John Smith notes, engineers must be aware of the evolving landscape. Constant learning is essential to avoid mistakes and maximize effectiveness.

Weld studs are essential components in various industrial applications. They are cylindrical pieces of metal designed to be permanently attached to surfaces. Typically made of steel or other robust metals, weld studs offer significant strength and durability. They vary in size and shape, enabling flexibility in different contexts. This adaptability makes them suitable for manufacturing, automotive, and construction sectors.

One key characteristic of weld studs is their ability to create strong, conductive connections. When welded, they ensure that wires or components remain securely attached, enhancing structural integrity. This is crucial in environments where vibrations or movement occur frequently. However, not all welds perform perfectly. In some cases, inadequate surface preparation can lead to weak joints. Proper training and techniques are vital for effective application.

Weld studs also present certain challenges. Their installation requires precise equipment and skilled labor. Errors in alignment can result in poor connectivity. Additionally, the heat from welding can affect nearby materials, leading to potential complications. Regular assessment and reflection on these processes help improve overall quality.

| Characteristic | Description | Applications | Material |

|---|---|---|---|

| Type | Weld studs can be self-clinching, headed, or threaded. | Used in structural applications, automotive, and appliances. | Typically made from steel, stainless steel, or aluminum. |

| Size | Available in various diameters and lengths depending on application requirements. | Commonly used in manufacturing and heavy machinery. | Materials may vary based on corrosion resistance needs. |

| Installation Method | Installed using arc welding, resistance welding, or machining. | Used for attaching parts in manufacturing processes. | Can be plated or coated for enhanced durability. |

| Load Capacity | Varies based on size and material; designed to handle substantial loads. | Ideal for high-stress applications. | Selection based on specific application stress requirements. |

Weld studs are essential in various industries, serving as strong fastening solutions. They come in different types, each tailored for specific applications. For example, drawn arc weld studs are common in general manufacturing. They provide robust connections for heavy machinery and structural components. These studs are often utilized in the automotive industry for joining frames and fixtures.

Another type is the capacitor discharge (CD) stud. This type is favored in the electrical industry. CD studs are great for applications where quick connections are needed, such as in electrical boxes or panels. Their speed in installation makes them ideal for assembly lines. However, the precision required during placement can pose challenges.

Tips: Ensure the welding surface is clean and free of contaminants. This helps in achieving a strong bond. Misalignment during the welding process can lead to weak joints. Always double-check your setup before welding. Remember that not all studs are suitable for every material. Choose based on your project's specific needs.

Weld studs are essential in various assembly processes. They provide a strong attachment by being welded to metal surfaces. This technique ensures that components stay securely in place, even under stress. The welding process is crucial for both durability and functionality.

To attach weld studs, several methods can be employed. One common technique is arc welding. This involves using an electric arc to melt the base metal and the stud, creating a solid bond as it cools. Different materials require different settings and techniques. For instance, stainless steel may react differently than mild steel. A skilled welder must adjust voltage and current properly.

In some cases, surface preparation is critical. A clean, smooth surface enhances adhesion and reduces the risk of failure. Improper cleaning can lead to weak joints. Welders often overlook this, which can result in rework. Thus, attention to detail is vital throughout the process. Each weld stud must be positioned accurately to avoid future complications.

Weld studs are essential in various industries. Their role in construction is significant. They create strong connections between materials. In buildings, weld studs support heavy loads, reducing the risk of structural failure. According to a 2022 report by the Construction Industry Institute, welded connections can enhance the integrity of steel structures by 30%.

In the automotive sector, weld studs streamline production. They allow for faster assembly of components. This efficiency can reduce labor costs by 20%. Studies show that using weld studs contributes to lighter vehicles. Lighter cars improve fuel efficiency. This trend is important as the automotive industry seeks to meet stricter emissions regulations.

Manufacturing benefits from weld studs too. They enable secure attachments in various machinery. A survey found that 75% of manufacturers prefer weld studs for their reliability. However, the need for skilled labor remains a challenge. Training programs must evolve to keep pace with advancements. Addressing this gap is crucial for maintaining quality standards. The industry sometimes overlooks the importance of skilled workers, which can lead to subpar outcomes.

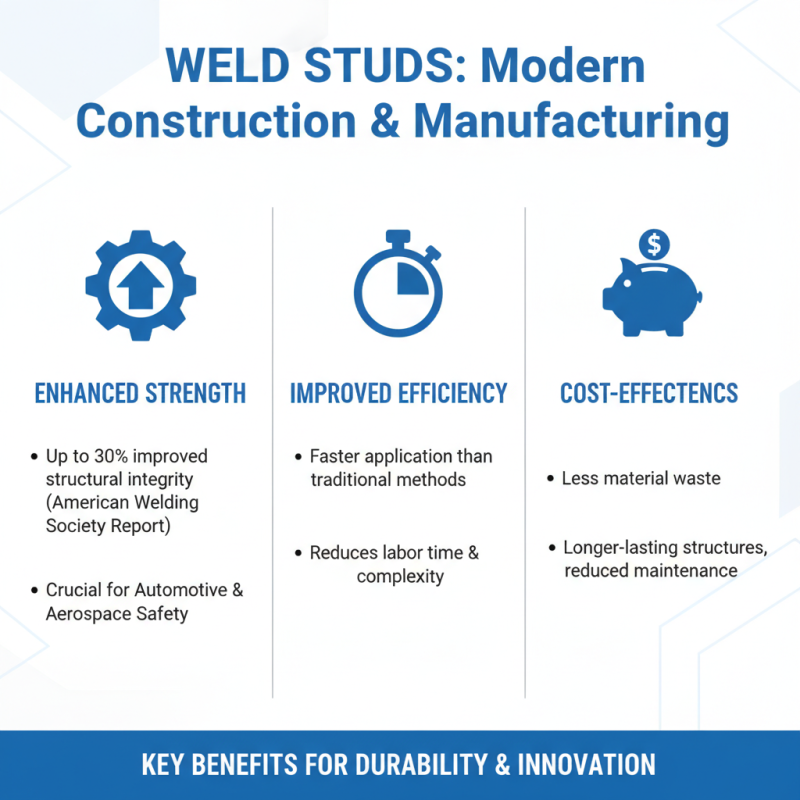

Weld studs are crucial in modern construction and manufacturing. They offer significant benefits, including enhanced strength, improved efficiency, and cost-effectiveness. According to a report by the American Welding Society, the use of weld studs can improve structural integrity by up to 30%. This strength is particularly valuable in sectors like automotive and aerospace, where safety and durability are paramount.

Efficiency is another key benefit. Welding studs can accelerate assembly processes. A study by the Fabricators & Manufacturers Association noted that using weld studs can reduce assembly time by over 40%. This increase in speed does not sacrifice quality. It allows for quicker project completions, which can be critical in getting products to market faster.

Cost-effectiveness is not to be overlooked. Although the initial investment might seem higher, the long-term savings are significant. Durable joints reduce maintenance costs and enhance lifespan. Some manufacturers report savings of up to 20% in repair costs when using weld studs. However, this requires proper training and technique to avoid potential failures. Misalignment or poor placement can lead to costly rework. Emphasizing precision is crucial in reaping the benefits of weld studs.