Neoprene washers are essential components in various sealing applications. They provide durability and flexibility, ensuring effective sealing solutions. John Smith, a renowned expert in the sealing industry, once remarked, “Neoprene washers are crucial for any project requiring reliability and performance.”

These washers excel in resisting oil, water, and chemicals. Their unique properties make them ideal for automotive, plumbing, and electronics uses. However, proper installation is vital; an improper fit can lead to leaks. Many overlook the importance of surface preparation before applying neoprene washers.

Selecting the right size is equally important. A washer that is too small or too large may fail to seal effectively. Users must understand the specific requirements of their projects. With the right guidance, the use of neoprene washers can significantly enhance sealing performance. Recognizing the need for quality materials is essential.

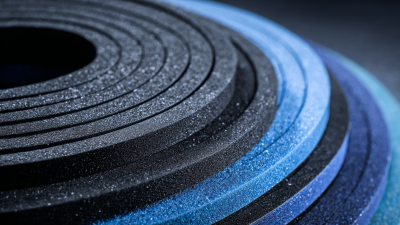

Neoprene washers are notable for their resistance to various environmental factors. They can withstand oil, water, and chemicals, making them suitable for many applications. In industrial settings, these washers often maintain integrity under extreme temperatures, with performance ranges typically between -40°F to 212°F. Such versatility makes neoprene a preferred material for sealing solutions.

The material properties of neoprene contribute significantly to its sealing capabilities. Its elasticity allows it to fill spaces tightly, ensuring that leaks are minimized. According to industry reports, neoprene washers can reduce leakage by as much as 80% in plumbing applications. However, improper installation can lead to failures. If the washer is not placed evenly, it might compress unevenly, leading to gaps.

Moreover, neoprene is also highly durable. It resists cracking and degradation, resulting in longer service life. While this appeal is clear, care must be taken with its exposure to UV light. Prolonged sunlight can weaken the material. Using neoprene washers in UV-intensive environments may require additional protective measures. For effective sealing, one must consider both the advantages and potential pitfalls of the material.

| Property | Description | Benefits |

|---|---|---|

| Material Composition | Made from a synthetic rubber blend | Durable and flexible for various applications |

| Temperature Resistance | Can withstand temperatures from -40°F to 220°F | Ideal for environments with extreme temperatures |

| Chemical Resistance | Resistant to oils, fuels, and many chemicals | Extends the life of seals in harsh conditions |

| Water Resistance | Offers excellent sealing against water ingress | Prevents leaks in plumbing and automotive applications |

| Installation | Easy to install without special tools | Saves time and reduces costs in maintenance |

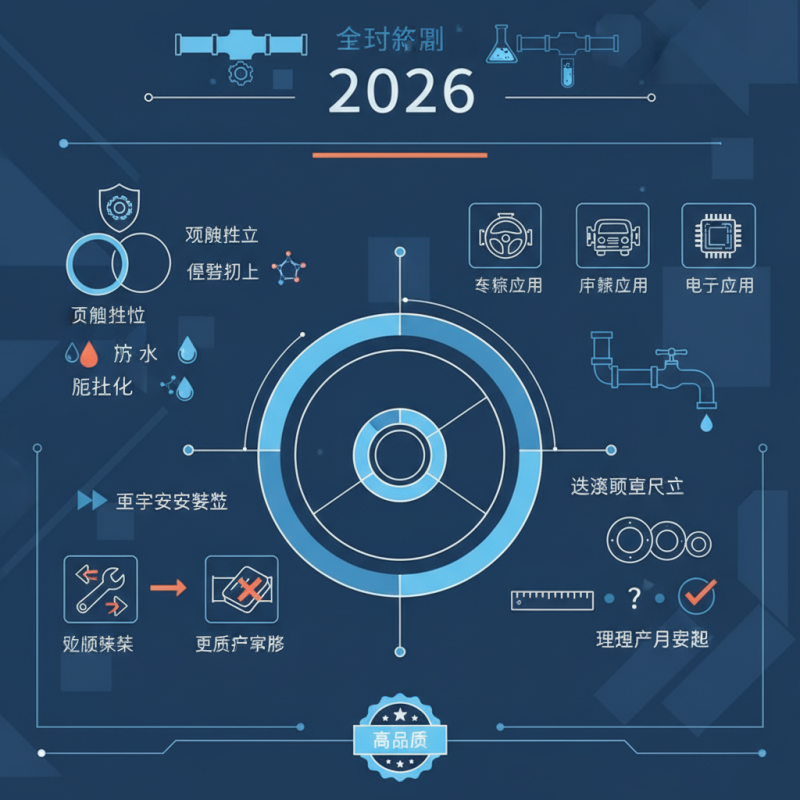

Neoprene washers are versatile components used across various industries. Their unique properties make them ideal for effective sealing. In construction, neoprene washers prevent leaks in pipes. They resist water, chemicals, and temperature changes. This durability extends the life of plumbing systems.

In automotive applications, neoprene washers minimize vibration and noise. They are used in engines and chassis assemblies. However, improper installation can lead to premature wear. In electronics, neoprene washers provide insulation between components. This helps in reducing electrical failures. It’s essential to ensure proper sizing for optimal performance.

Despite their many advantages, neoprene washers can be overused in certain settings. In environments with extreme temperatures, performance may decline. Regular monitoring is key. Identifying when to replace these washers can be challenging. Users should always assess their conditions to avoid costly mistakes.

This bar chart illustrates the frequency of neoprene washer applications across various industries, highlighting their widespread use in automotive, aerospace, and construction sectors.

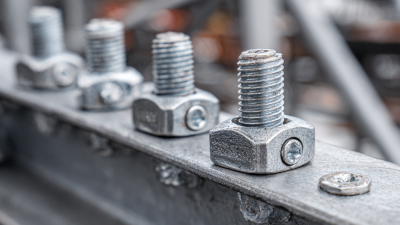

Installing neoprene washers can greatly improve sealing in various applications. The process is relatively simple but requires attention to detail. Begin by gathering your tools: a wrench, scissors, and a clean cloth. Make sure the surfaces where the washers will sit are clean and free from debris. This ensures a better seal.

Once your surfaces are prepared, place the neoprene washer onto the screw or bolt you intend to use. Press down gently to ensure it sits evenly. Depending on the environment, you might need different sized washers for optimal sealing. Sometimes, the fit may feel too tight or too loose. It’s essential to adjust accordingly. Check and recheck to avoid mistakes that could lead to leaks.

After installation, tighten the bolt or screw gradually. Over-tightening can lead to material degradation. A common error is not considering the temperature variations where the washers are used. Neoprene can expand or contract, affecting the seal. It’s wise to monitor installations periodically. Look for signs of wear or leakage, and replace as needed. Remember, not every installation goes perfectly the first time. Continuous improvement helps achieve better results.

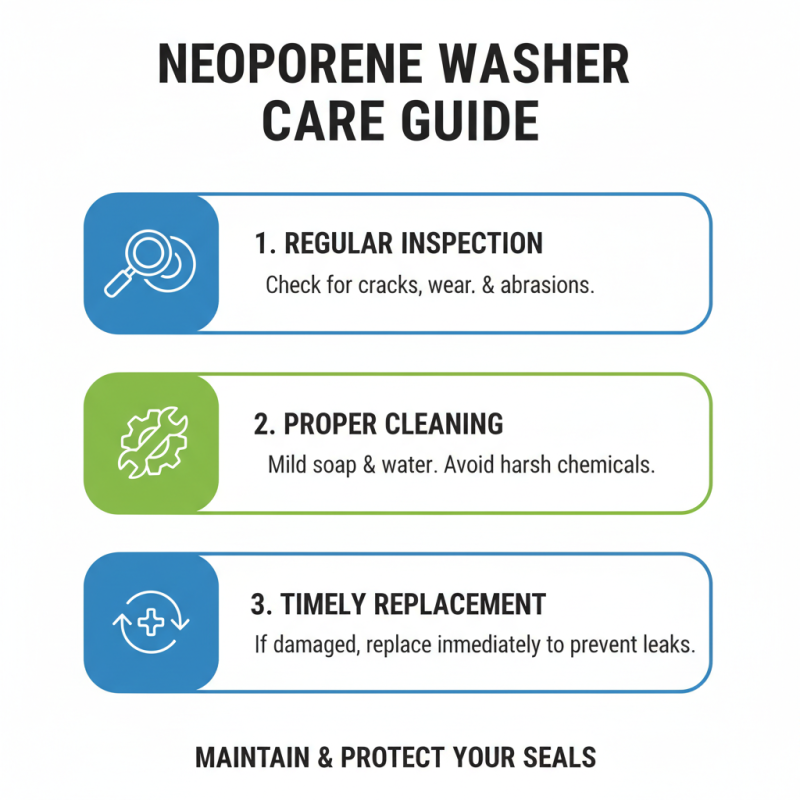

Neoprene washers are widely used for sealing applications. To ensure they last longer and remain effective, proper maintenance is crucial. Regularly inspect these washers for signs of wear, such as cracks or abrasions. If you notice any damage, replace them immediately to prevent leaks.

Another important aspect is cleaning. Clean the washers gently with a mild soap solution. Avoid harsh chemicals that can degrade neoprene material. Rinse thoroughly and allow them to dry completely before reinstalling. Moisture trapped on the washers may lead to reduced sealing performance over time.

Storage also matters. Keep neoprene washers in a cool, dry place. Extreme temperatures can cause deterioration. Avoid exposure to direct sunlight, as UV rays can weaken the material. By taking these simple maintenance steps, you can enhance the longevity and effectiveness of your neoprene washers. Remember, small actions lead to better results.

When using neoprene washers, avoiding common mistakes is crucial for effective sealing. One frequent error is not considering the washer's thickness. A washer that is too thin may not create a proper seal. Conversely, a washer that is too thick can lead to overstressing and damage to surfaces.

Another mistake is neglecting proper installation techniques. It's important to clean the surfaces before applying the washer. Dirt and debris can hinder the seal's effectiveness. Pay attention to the alignment of the washer, as a misaligned seal can lead to leaks.

Tips: Make sure the temperature is right when applying neoprene washers. Extreme temperatures can compromise their sealing ability. Additionally, regularly inspect the seals, as wear and tear can occur over time. Don’t forget to replace washers that show signs of deterioration. Sealing solutions should not be an afterthought; they require attention and care for optimal performance.