In today's competitive manufacturing landscape, the importance of selecting the right materials for projects cannot be overstated. Neoprene washers, known for their excellent durability, flexibility, and resistance to environmental factors, have emerged as a critical component in various applications from automotive to construction industries. According to a report by MarketsandMarkets, the global gasket and sealing materials market, which includes neoprene products, is projected to reach USD 24.8 billion by 2027, reflecting a compound annual growth rate of 5.0% from 2022. This surge highlights the increasing demand for reliable sealing solutions, emphasizing the pivotal role that neoprene washers play in ensuring the integrity and longevity of engineered systems. As we explore the advantages of using the best neoprene washers for your projects, it becomes evident that leveraging this innovative material will not only enhance performance but also contribute to overall project efficiency and sustainability.

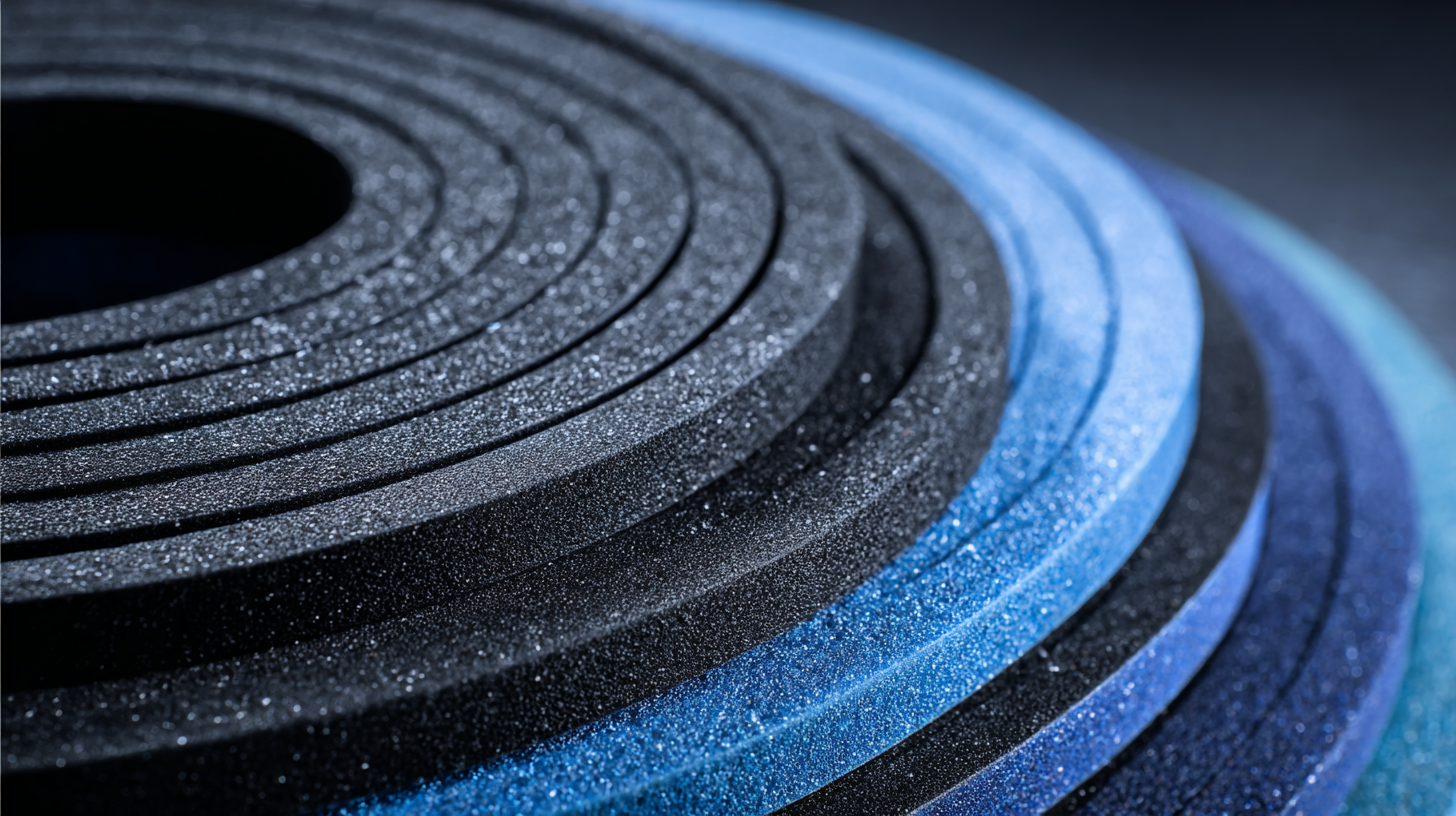

Neoprene washers are gaining traction in various applications due to their unique properties, which include water resistance, flexibility, and strong chemical stability. These advantages allow them to function effectively in a broad range of conditions, from plumbing and electrical installations to automotive and industrial applications. According to industry reports, the neoprene market is expected to reach USD 1.68 billion by 2027, driven by the growing demand for high-performance materials that can withstand extreme environments.

Moreover, as the trend toward sustainability continues to influence design decisions, manufacturers are increasingly recognizing the benefits of using fasteners, such as neoprene washers, over traditional methods like welding. The recent shift towards the "Right to Repair" movement emphasizes the need for components that are easy to replace and maintain. Fasteners not only simplify repairs but also enhance the overall sustainability of products by facilitating disassembly. In fact, a study indicated that products designed for easy repair can reduce waste by up to 80%, showcasing the potential for neoprene washers in supporting eco-friendly practices across industries.

As we look ahead to 2025, several key technical trends are shaping the development of neoprene washers, a crucial component in various industrial applications.

Generative AI is increasingly being integrated into the manufacturing processes, enhancing precision and efficiency in producing neoprene products. Reports suggest that companies embracing these technologies can expect significant gains in productivity and reduced operational costs, further solidifying neoprene's role in diverse projects from automotive to electronics.

A notable trend is the rise of advanced materials technology, which is driving innovations in the formulation of neoprene. These improvements not only enhance the durability and resistance of washers, but also promote sustainability. Research indicates that incorporating eco-friendly additives can reduce the environmental footprint of neoprene production without compromising performance.

Tips: When selecting neoprene washers for your projects, consider those produced with advanced materials technology to ensure longevity and reliability. Additionally, leveraging AI-driven tools in your supply chain can optimize inventory management and reduce waste. Always verify the performance characteristics of neoprene washers to align with your project’s specific requirements for optimal outcomes.

When selecting the right neoprene washer for your needs, it's essential to consider factors such as size, hardness, and application specifics. According to a report by the Rubber Manufacturers Association, neoprene is known for its durability and resistance to oil and temperature variations, making it an excellent choice for a wide range of projects. Choosing the right thickness and diameter ensures a proper fit, which is critical for sealing applications in plumbing, automotive, and electrical industries.

Additionally, understanding the material composition is vital. Neoprene washers come in various grades, with different properties suited for specific environments. For instance, a recent study indicated that Neoprene A has a tensile strength of approximately 1,500 psi, which makes it highly effective in applications requiring high resistance to wear and tear. By assessing the environment in which the washer will operate—whether exposed to chemicals or extreme temperatures—you can ensure that you select a neoprene washer that will not only provide a reliable seal but also enhance the longevity of your projects.

When it comes to improving the efficiency and durability of your projects, incorporating neoprene washers can make a significant difference. One innovative technique involves using these washers in environments prone to vibrations, such as machinery or automotive applications. The elastic properties of neoprene allow it to absorb shocks and maintain a tight seal, preventing leaks and enhancing overall performance. By strategically placing neoprene washers between parts that experience friction or movement, you can minimize wear and extend the lifespan of your equipment.

Another effective method to implement neoprene washers is in waterproofing applications. Their resistance to water and various chemicals makes them ideal for use in plumbing and outdoor projects. For instance, when sealing joints in plumbing fixtures, using neoprene washers can prevent leaks and protect against corrosion. Additionally, incorporating a variety of sizes and thicknesses allows for customized solutions that cater to the specific requirements of your project, minimizing failures and ensuring lasting functionality. Integrating these innovative techniques into your designs will undoubtedly elevate the quality and reliability of your work.

| Property | Description | Advantages | Applications |

|---|---|---|---|

| Material Type | Neoprene rubber | Durable and flexible | Automotive, industrial applications |

| Temperature Resistance | -40°C to 120°C | Works in extreme temperatures | Sealing, insulation |

| Water Resistance | Excellent resistance to moisture | Prevents leaks and damage | Plumbing, electronics |

| Chemical Resistance | Resistant to oils, greases | Long-lasting performance | Manufacturing, automotive |

| Ease of Use | Flexible and easy to install | Saves installation time | DIY projects, repairs |

When it comes to selecting the right washers for your projects, neoprene washers stand out among various materials due to their superior flexibility and resistance to water, oil, and various chemicals. Unlike traditional rubber or plastic washers, neoprene offers excellent durability, making it suitable for both indoor and outdoor applications. Its unique properties enable it to withstand significant temperature fluctuations, which is a crucial factor to consider in many industrial and construction settings.

In comparison to materials such as silicone or metal, neoprene washers provide a better balance between sealing ability and cost-effectiveness. While silicone may offer higher heat resistance, it often comes at a premium price. Metal washers, although strong, can corrode when exposed to moisture. Neoprene’s resilience to abrasion and its ability to maintain a tight seal under pressure make it an ideal choice for plumbing, automotive, and machinery projects. Overall, the comparative analysis reveals that neoprene washers deliver both performance and value, effectively addressing the needs of various applications.