Choosing the right Aluminum Rivets for your projects can make a significant difference. According to industry expert John Smith, “The right rivet can elevate the quality of your work.” His insight highlights the importance of making informed choices.

Aluminum Rivets are lightweight yet surprisingly strong. They are often used in various applications, from automotive to construction. Selecting the right type involves understanding specifications like diameter, grip range, and strength. Mistakes can lead to structural failures.

It is essential to consider the environment where the rivets will be used. Factor in elements like moisture and temperature fluctuations. Not all Aluminum Rivets are made equal. A common oversight is ignoring these conditions. In the end, making thoughtful decisions about Aluminum Rivets can lead to more successful projects.

When selecting aluminum rivets, it's essential to understand the various types available. Aluminum rivets come in different forms, including solid, blind, and tubular rivets. Solid rivets are very strong and provide a permanent bond. They are often used in structural applications. Blind rivets, on the other hand, are useful when access is limited on one side of the material. They expand when installed, providing a secure hold. Tubular rivets have a hollow body, allowing them to be lighter but may not offer the same level of strength.

Each type of rivet has unique attributes that suit specific projects. The size and grip range are crucial factors when selecting which rivet to use. An incorrect size can lead to weak joints or even rivet failures. Additionally, consider the environment where the rivets will be used. Corrosive environments may require special coatings or materials. Remember that not all aluminum rivets are the same; their manufacturing quality can vary greatly. Testing a sample before large-scale use can save time and resources.

When selecting aluminum rivets, strength is a critical consideration. Different projects require different strength levels. If you’re joining lightweight materials, standard aluminum rivets may suffice. However, for structural applications or situations subjected to heavy loads, you need rivets designed to withstand those stress levels. Evaluate the materials you are working with. Their combined weight can influence your choice significantly.

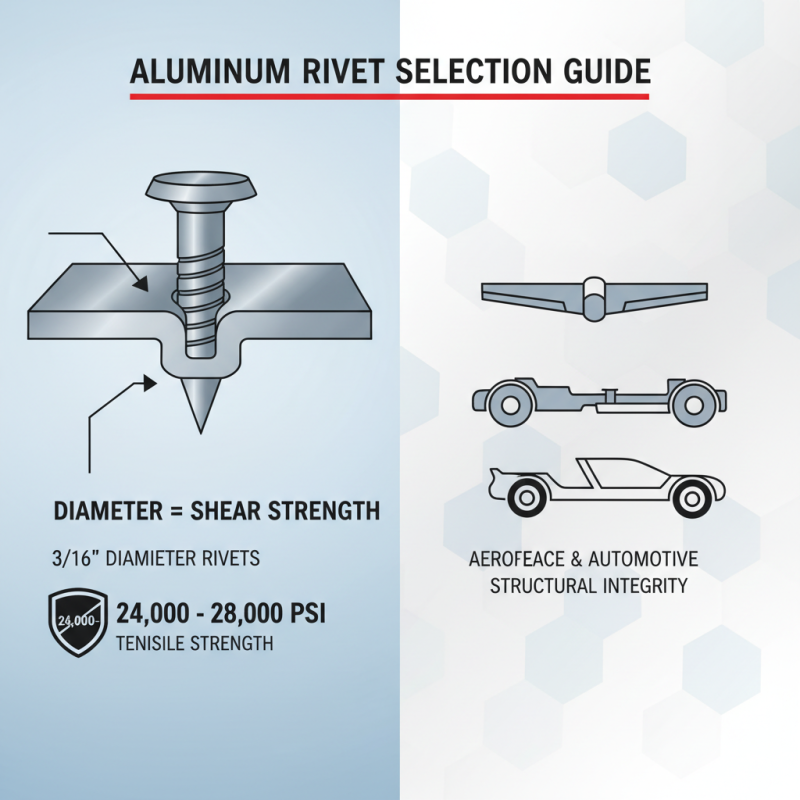

Make sure to assess the shear and tensile strength of the rivets. Shear strength measures how much force the rivet can withstand before it fails. Tensile strength evaluates the rivet's ability to resist being pulled apart. These factors are essential in ensuring structural integrity. Check the specifications of the rivets before making a final decision. Remember, sometimes the standard choices might not fit your specific requirements perfectly. Make adjustments as needed.

Reflect on the environment where the rivets will be used. Corrosion and weather conditions can weaken them over time. You might need to choose rivets with protective coatings or consider alternative materials. Don’t rush this evaluation. Taking the time to analyze all these factors can save you from potential failures in the future. Balancing strength and project demands is vital.

| Tip | Description | Strength Requirement | Common Uses |

|---|---|---|---|

| 1. Determine Load Type | Assess if the load is static or dynamic. | Low to High | Construction, Automotive |

| 2. Material Grade | Select the appropriate aluminum grade for strength. | Medium to High | Aerospace, Maritime |

| 3. Rivet Size | Choose the correct diameter and length. | Variable | General Joining |

| 4. Corrosion Resistance | Assess environmental exposure and select coated options. | Medium | Outdoor Applications |

| 5. Installation Method | Decide between manual and pneumatic application. | Low | DIY Projects |

| 6. Joint Accessibility | Consider the space available for riveting. | Variable | Automotive, Machinery |

| 7. Shock Absorption | Choose rivets that allow flexibility where needed. | Medium | Electronics, Sports Equipment |

| 8. Weight Consideration | Ensure rivets are lightweight for specific applications. | Low | Aerospace, Automotive |

| 9. Testing for Strength | Perform tests to verify strength before application. | High | Structural Assembly |

| 10. Cost Efficiency | Balance quality with budget constraints. | Low to Medium | General Construction |

When selecting aluminum rivets, corrosion resistance is a critical consideration. Aluminum excels in environments prone to moisture and harsh chemicals. Research indicates that high-grade aluminum rivets can withstand corrosion better than standard alloys. According to a study by the Naval Engineering Journal, up to 60% of structural failures in marine applications are linked to poor corrosion resistance. Choosing the right alloy can significantly enhance durability.

Environmental factors also play a vital role in rivet selection. UV exposure, temperature fluctuations, and saltwater environments can all impact an aluminum rivet's lifespan. In coastal areas, the presence of salt can accelerate corrosion. It is essential to evaluate the specific conditions of your project site. The American Society for Testing and Materials suggests testing aluminum rivets in simulated environmental conditions. This testing can provide insights into how rivets behave under actual operating conditions.

While it's tempting to choose only the cheapest option, investing in higher quality aluminum rivets pays off. Reduced maintenance and fewer replacements lead to long-term savings. A poorly chosen rivet may lead to project delays or failures. Thus, it’s crucial to thoroughly assess corrosion resistance and environmental impacts when making your selection. Consider the trade-offs between cost and durability.

Choosing the right size and diameter of aluminum rivets is crucial for effective joining in various projects. The diameter directly influences the rivet's shear strength. Industry studies indicate that rivets with a diameter of 3/16" offer a tensile strength ranging from 24,000 to 28,000 PSI. This strength is essential for ensuring structural integrity in applications like aerospace and automotive manufacturing.

However, selecting the wrong size can lead to complications. Rivets that are too small may fail under pressure, resulting in joint failure. On the other hand, oversized rivets can damage materials during installation. It’s important to refer to guidelines such as those outlined by the American National Standards Institute (ANSI), which recommend specific diameters based on material thickness. They suggest using larger rivets for thicker materials but caution against exceeding recommended sizes, which could compromise strength.

When determining size, consider both the application and material type. For instance, the joining of aluminum to aluminum requires different specifications than joining aluminum to steel. Design flaws can surface if adjustments aren’t made. Always take time to assess your project's needs carefully. This approach minimizes wasted materials and enhances the overall quality of your work. Properly sized rivets lead to more durable and reliable assemblies.

Choosing the right tools and techniques for riveting aluminum is crucial. Aluminum, while lightweight, can be challenging to work with. The strength of the rivet and its proper installation determine the longevity and integrity of the project. A study by the American Welding Society indicates that improper riveting could decrease the overall strength by 20%.

When selecting tools, consider the rivet gun. Manual and pneumatic options are common. A pneumatic rivet gun can increase efficiency significantly. Workers report a 50% reduction in installation time with pneumatic tools. Precision is vital; even a small error can lead to structural failure. Always ensure the proper grip is used. This affects the rivet's compression and strength.

Techniques also matter. Start with cleaning the surfaces. Any debris can weaken the bond. Use a countersink bit for better fit, enhancing rivet performance. Many professionals note that not all projects require the same technique. Review past projects and learn from mistakes. Reflect on what may have gone wrong, and adapt accordingly. Regular training and skill updates are key to mastering aluminum riveting.