In the rapidly evolving world of construction and manufacturing, the importance of small screws cannot be overstated. As they serve as crucial components in a vast array of projects—from furniture assembly to intricate electronic devices—their significance in ensuring durability and reliability is paramount. Renowned industry expert, Dr. Helen Carter, a leading figure in fastener technology, once stated, "The right small screw can make or break a project; it's the unsung hero of assembly engineering." This emphasizes the critical role that small screws play in the success of various applications.

As we delve into the Top 2025 Small Screws Guide, it becomes apparent that understanding the diverse types and specifications of small screws is essential for both professionals and DIY enthusiasts alike. Selecting the appropriate screw not only enhances the structural integrity of a project but also influences its efficiency and cost-effectiveness. Throughout this guide, we will explore the different categories of small screws, their unique features, and how they cater to the distinct needs of various industries.

In the following sections, we will equip you with the necessary knowledge to navigate the complexities of small screws, ensuring that you approach each project with confidence and expertise. Whether you are a seasoned professional or a casual hobbyist, understanding the intricacies of small screws will provide you with the foundation to achieve optimal results in your endeavors.

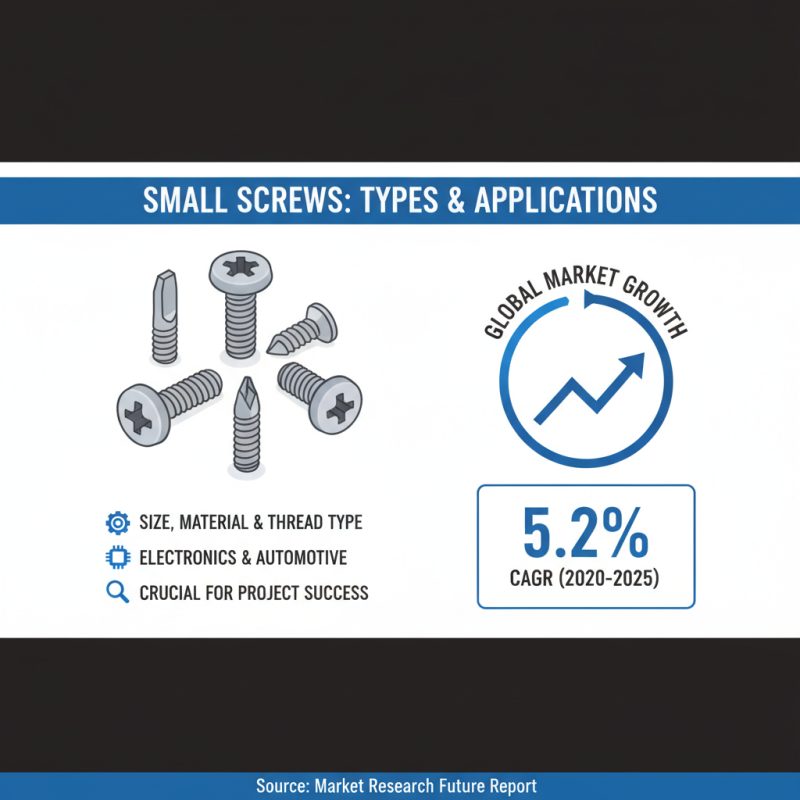

When it comes to small screws, understanding their various types and applications is essential for ensuring the success of any project. Small screws, often categorized by their size, material, and thread type, play a crucial role in industries ranging from electronics to automotive manufacturing. For example, according to a report by Market Research Future, the global market for small screws is expected to grow at a CAGR of around 5.2% from 2020 to 2025, highlighting their enduring importance in diverse applications.

One key type of small screw is the micro screw, typically defined as being less than 3mm in diameter. These screws are vital in precision instruments and electronic devices where space is limited. In contrast, wood screws are designed with coarse threads and sharp points that allow for easy driving into wood materials, making them ideal for furniture construction and carpentry projects. Data from the Fastener Industry Coalition indicates that approximately 25% of all fasteners used in construction are small screws, underscoring their significance in building integrity and product durability.

Furthermore, the material composition of small screws can greatly influence their performance. Stainless steel, for instance, offers excellent corrosion resistance, making it suitable for outdoor applications and environments with exposure to moisture. Conversely, brass screws are often favored for aesthetic purposes in decorative applications due to their appealing appearance. A survey by the Industrial Fasteners Institute reveals that over 60% of manufacturers prefer using high-quality materials for small screws to enhance longevity and reliability, further emphasizing the need for careful selection based on specific project requirements.

When selecting small screws for various projects, an essential aspect to consider is the material composition, which directly influences both strength and corrosion resistance. Common materials used for small screws include stainless steel, carbon steel, aluminum, and brass, each offering unique benefits and limitations.

Stainless steel, for instance, is highly regarded for its exceptional corrosion resistance properties, making it ideal for outdoor or marine applications where moisture and salt exposure are common. Its strength is substantial, suitable for high-stress applications, although it tends to be more costly than other materials.

On the other hand, carbon steel is known for its mechanical strength and toughness, often preferred in applications requiring durability and load-bearing capability. However, its susceptibility to rust necessitates protective coatings or treatments, especially in environments prone to corrosion.

Aluminum screws are lightweight and resistant to corrosion but may lack the strength required for heavy-duty applications. Brass screws serve as a good midpoint, offering decent strength and corrosion resistance, particularly outside. Thus, a comprehensive understanding of these materials ensures the optimal selection of small screws tailored to specific project needs, balancing performance and durability effortlessly.

When considering the selection of small screws for various applications, understanding sizing and measurement standards is crucial. Small screws typically fall under standardized dimensions that can vary between industries, with common sizes ranging from M1.6 to M10 according to ISO standards. The American National Standards Institute (ANSI) also provides guidelines that are vital for applications in aerospace, automotive, and electronics industries, where precision and reliability are essential. Research indicates that selecting the correct screw size and type can enhance performance by up to 30%, reducing the risk of mechanical failure.

Tip: Always reference the specific industry standards relevant to your project. For example, the automotive sector often adheres to dimensions defined by ISO 4762, which specifies screw lengths and head types that ensure optimal functionality in high-stress environments.

In addition to size, measuring the screw's tensile strength, usually indicated in the specifications, is essential. Various industries utilize screws with specific tensile strengths tailored to withstand different loads. For instance, a report by the American Society for Testing and Materials (ASTM) notes that screws used in structural applications may require a minimum tensile strength of 630 MPa to ensure safety and durability under load.

Tip: Conduct a thorough analysis of the load conditions your screws will face. Using screws that meet or exceed the required tensile strength can significantly extend the life of your project and enhance overall safety.

The design of threads in small screws is critical to their performance across various applications, influencing factors such as tensile strength, resistance to stripping, and overall durability. According to a report from the Industrial Fasteners Institute, nearly 70% of mechanical failures in engineered assemblies can be traced back to inappropriate thread design. This highlights the importance of selecting the right thread profile for specific materials and load conditions. For instance, finer threads offer increased holding power in softer materials, while coarse threads are better suited for harder substrates, providing superior grip and resistance to pull-out forces.

Additionally, thread design plays a pivotal role in ensuring consistent torque control during installation. Research published in the Journal of Mechanical Engineering indicates that screws with optimally designed threads can reduce the risk of over-tightening and enhance joint integrity, which is crucial in applications where safety is paramount. The implementation of advanced thread geometries, such as self-tapping and locking threads, can further enhance performance, mitigate stripping risks, and accommodate variations in material thickness. This advancement in design paradigms signifies a shift towards more efficient and reliable fastening solutions in contemporary engineering projects.

| Screw Type | Diameter (mm) | Length (mm) | Thread Design | Material | Application |

|---|---|---|---|---|---|

| Screw A | 2.5 | 10 | Coarse | Steel | Electronics |

| Screw B | 3.0 | 12 | Fine | Stainless Steel | Furniture |

| Screw C | 4.0 | 15 | Self-Tapping | Brass | Construction |

| Screw D | 2.0 | 8 | Metric | Aluminum | Automotive |

| Screw E | 3.5 | 20 | Truss | Plastic | Home Appliances |

When it comes to installing small screws, proper techniques can significantly impact the durability and effectiveness of your projects. Begin by ensuring that the materials you are working with are appropriate for the type of small screw you plan to use. Different materials require different pilot hole sizes; for instance, hardwoods may need a slightly larger pilot hole compared to softer woods to prevent splitting. Additionally, using the correct screwdriver or bit is crucial; mismatched sizes can strip the screw head and compromise the integrity of the connection.

Regular maintenance of small screws is equally important to ensure long-lasting performance. Periodically inspect screws for signs of corrosion or loosening, especially in environments with high humidity or exposure to chemicals. If you notice any screws becoming loose, gently tighten them using the appropriate tool, taking care not to overtighten, which can lead to material damage. When replacing screws, always consider the specific requirements of your application, including length, diameter, and thread type, to maintain the structural integrity of your project. By following these best practices, you can ensure that small screws perform optimally across a variety of applications.