In construction and woodworking, Hanger Bolts are essential fasteners. They bridge the gap between wood and metal. These versatile bolts have a unique design that allows for secure attachment. Their threaded ends make them suitable for various applications.

Understanding the top Hanger Bolts can elevate your projects. Whether you are building furniture or frameworks, these bolts play a critical role. Different types have distinct characteristics, which can affect functionality. Some may struggle with specific weight requirements. Choosing the right one is crucial to avoid setbacks.

This guide explores the top 10 Hanger Bolts. It emphasizes the importance of selecting high-quality options. You’ll find insights on durability and load-bearing capacity. These details often determine the success or failure of your project. Don’t overlook the nuances; even small choices matter significantly.

Hanger bolts are crucial fastening elements in construction and woodworking. They consist of a hex head on one end and wood screw threads on the other. This design allows them to anchor materials like wood, concrete, or metal. According to industry reports, the global demand for hanger bolts has seen a steady increase of about 5% annually, as more industries recognize their versatility and efficiency.

When using hanger bolts, consider the load they will bear. A properly chosen bolt can support significant weight without compromising structure. Overloading a hanger bolt can lead to failures, which may cause structural instability. It’s essential to match the bolt's size and strength to your specific application.

Tips: Always pre-drill holes when installing hanger bolts. This helps prevent wood splitting and ensures a snug fit. Keep in mind, not all materials are compatible with every type of hanger bolt. Doing careful research will save you time and frustration. If possible, consult with professionals or reference engineering tables for guidance on weight limits and sizes. You may find that sometimes, even minor oversights lead to significant issues.

| Hanger Bolt Type | Length (inches) | Diameter (inches) | Material | Purpose |

|---|---|---|---|---|

| Standard Hanger Bolt | 4 | 1/2 | Steel | Hanging fixtures |

| Lag Hanger Bolt | 5 | 3/8 | Stainless Steel | Heavy-duty applications |

| Zinc-Plated Hanger Bolt | 6 | 1/4 | Zinc | Indoor use |

| Heavy Hex Hanger Bolt | 3 | 5/8 | Carbon Steel | Structural applications |

| Adjustable Hanger Bolt | 4.5 | 1/2 | Aluminum | Adjustable fixtures |

| Wood Hanger Bolt | 2 | 3/8 | Wood | Joining wood components |

| Square Hanger Bolt | 5 | 1/4 | Steel | Specialty mounting |

| Stud Hanger Bolt | 4 | 3/8 | Brass | Decorative fixtures |

| Tapered Hanger Bolt | 6 | 1/4 | Steel | Applications requiring a strong hold |

| Plastic Hanger Bolt | 3 | 1/2 | Plastic | Lightweight fixtures |

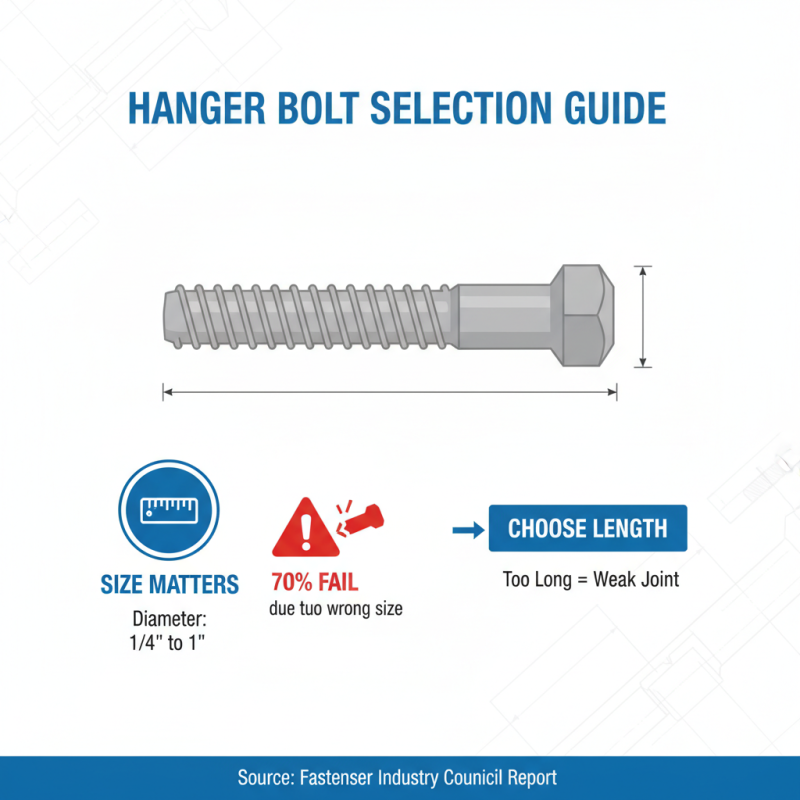

When selecting hanger bolts, certain key features are crucial. The size is a primary consideration. Most projects require bolts ranging from 1/4 inch to 1 inch in diameter. A report by the Fastener Industry Council indicates that 70% of failures in assemblies relate to improper sizes. This highlights the importance of accurate measurements. Choose the appropriate length too. A bolt that’s too long can weaken the joint's stability.

Material composition impacts performance as well. Common materials include steel, stainless steel, and brass. Steel is strong and cost-effective, while stainless steel resists corrosion. According to a study by the American Fasteners Institute, joints using stainless steel bolts show a 50% increase in longevity in outdoor conditions. Balancing cost and durability is essential. Users often overlook this aspect and face rust issues later.

Thread type matters, too. Coarse threads provide quick assembly, while fine threads offer better tension control. About 60% of engineers prefer fine threads for precision. Consider the application. For instance, heavy workloads may necessitate stronger options. Many projects suffer from using inappropriate hangers and facing disappointment. It's all about finding the right combination of features for your specific needs.

When it comes to construction and woodworking, hanger bolts play a crucial role. They are specially designed fasteners used for connecting various components. Understanding the different types of hanger bolts can significantly enhance your project efficiency.

Common types include standard hanger bolts. These have coarse threads on one end and finer threads on the other. They're perfect for both wood and metal applications. Another type is lag hanger bolts, ideal for heavy-duty support. They provide exceptional strength for projects like shelving or furniture. Also, there's the hook-style hanger bolt. This variation allows for easy attachment of items, making it versatile for various applications.

While having the right type matters, sometimes selecting the wrong size can lead to issues. A bolt that is too long may strip, while a short one can fail under pressure. Always check compatibility with the materials being used. This small step often gets overlooked in many projects. The key is to learn from past mistakes. A minor detail, like the thread type, can impact the entire structure's stability.

Hanger bolts are essential in various construction projects. Their installation can significantly impact structural integrity. Proper techniques ensure that the bolts perform as intended. According to industry reports, improperly installed bolts can lead to a 25% increase in stress on the joint. This is critical data for anyone working with these fasteners.

When installing hanger bolts, start with precise alignment. Measure carefully before drilling. A misaligned hole can compromise the whole structure. Use a pilot hole to guide the bolt, which minimizes the risk of splitting the wood or damaging the material. Remember, even minor errors can have larger consequences, affecting load-bearing capacities.

Tip: Always check your torque settings. Over-tightening can weaken the bolt. It is also wise to use the right washer. A washer helps distribute stress evenly across the surface, enhancing stability. Many professionals overlook this detail, leading to potential failures.

Another key factor is to consider the type of material you're working with. Different materials may require specific techniques and care. For example, softer woods may strip more easily. Keep this in mind when selecting your bolts and installation methods. It’s important to reflect on these details to avoid costly mistakes in your projects.

Hanger bolts play a crucial role in various construction projects. Maintaining them properly is essential for their longevity. According to industry reports, improper maintenance can lead to a 30% decrease in hardware performance over time.

Regular inspections are key. Check for signs of corrosion or wear. A small amount of rust can reduce the bolt's load capacity. Replace any damaged bolts immediately. Lubricating the threads with the right oil can significantly improve their lifespan. Research shows that well-lubricated bolts can last up to 40% longer than dry ones.

Additionally, store hanger bolts in a cool, dry place. High humidity can lead to premature corrosion. Using a dehumidifier can be beneficial in such environments. Something as simple as ensuring proper storage can make a difference. Always be mindful of the materials used in conjunction with hanger bolts. Some materials can cause galvanic corrosion, impacting their effectiveness.

Understanding the load capacities of different hanger bolts is crucial for ensuring the safety and longevity of your projects. This chart illustrates the load capacities of the top 10 hanger bolts, helping you make informed decisions for your construction needs.