When it comes to home improvement projects, the importance of selecting the right materials cannot be overstated. One crucial component is the Dry Wall Screws. These screws are specifically designed for attaching drywall to wooden or metal studs. According to industry reports, using the wrong fasteners can compromise the integrity of your walls, leading to costly repairs. In fact, studies show that over 30% of drywall issues stem from improper installation practices.

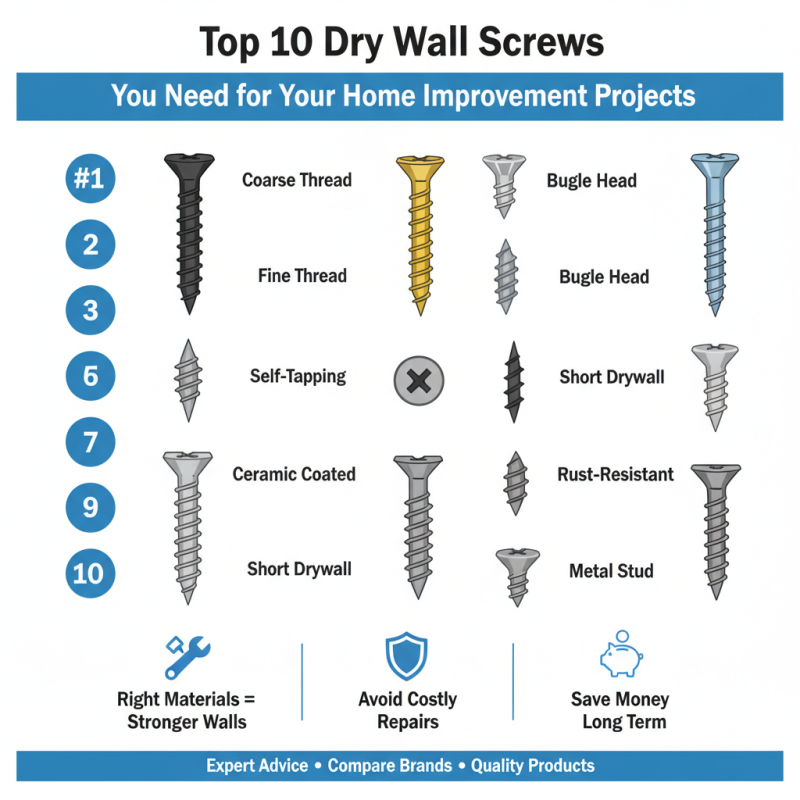

Understanding different types of Dry Wall Screws is essential. They vary in coatings, thread design, and length. For instance, screws with a promoted coating resist rust, ensuring durability. Also, the thread design significantly affects the grip on the drywall. Often, DIY enthusiasts overlook these specifics, resulting in unexpected failures. Identifying the right screw type is critical to a successful project.

Budget-conscious homeowners may be tempted to buy cheaper options. However, cheaper screws can lead to problems like cracking or warping over time. This is where understanding the nuances of Dry Wall Screws becomes vital. Homeowners should invest time in researching and selecting quality products. It can save money in the long run and enhance the stability of their walls. Consider seeking out expert advice and comparing brands before making a purchase.

When embarking on home improvement projects, having the right drywall screws is crucial. These screws come in various sizes and types, catering to different materials and purposes. Understanding the characteristics of each type can significantly impact your project's success.

For example, coarse-thread screws work well for attaching drywall to wood studs. In contrast, fine-thread screws are better suited for metal studs. When buying screws, consider length as well. Longer screws provide better hold, but may crack thinner materials.

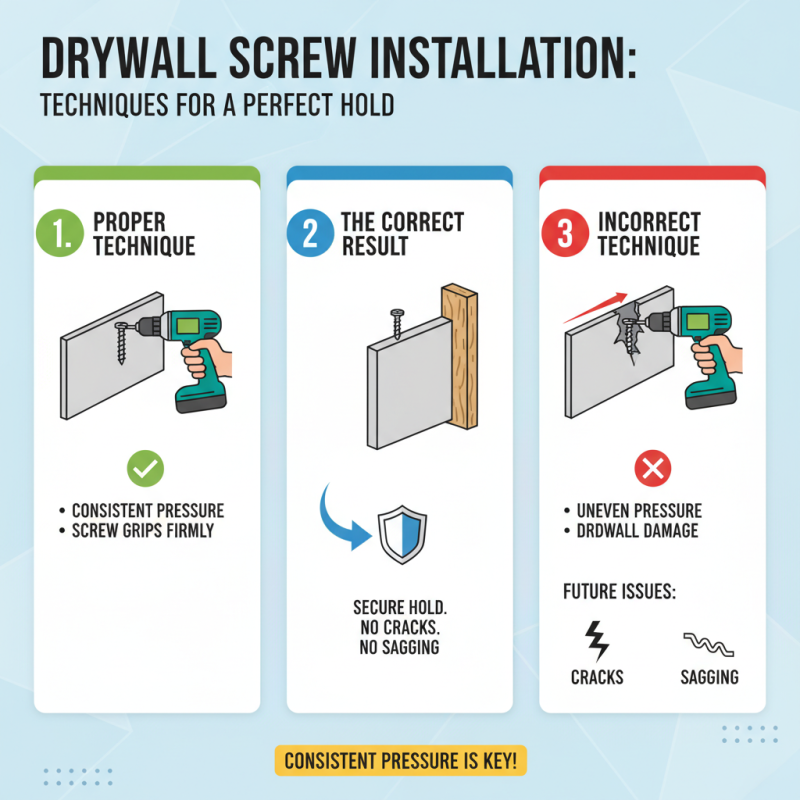

**Tip:** Always pre-drill your holes. This reduces the chance of cracking and makes installation smoother. Also, use a screw gun to prevent over-driving and damaging the drywall. Pay attention to the screw spacing; too close can weaken the structure, while too far can cause sagging over time. Planning well can save you headaches later!

Keep in mind that not all screws are created equal. Double-check their specifications. Sometimes, an inexpensive option can lead to problems down the line. Choose wisely, and remember that investing in quality pays off in the long run.

Understanding the different types of drywall screws can significantly enhance your home improvement projects. Drywall screws come in various sizes and coatings. Choosing the right one is essential for the strength and longevity of your build. For instance, coarse-thread screws are excellent for wood studs, while fine-thread screws work best with metal studs.

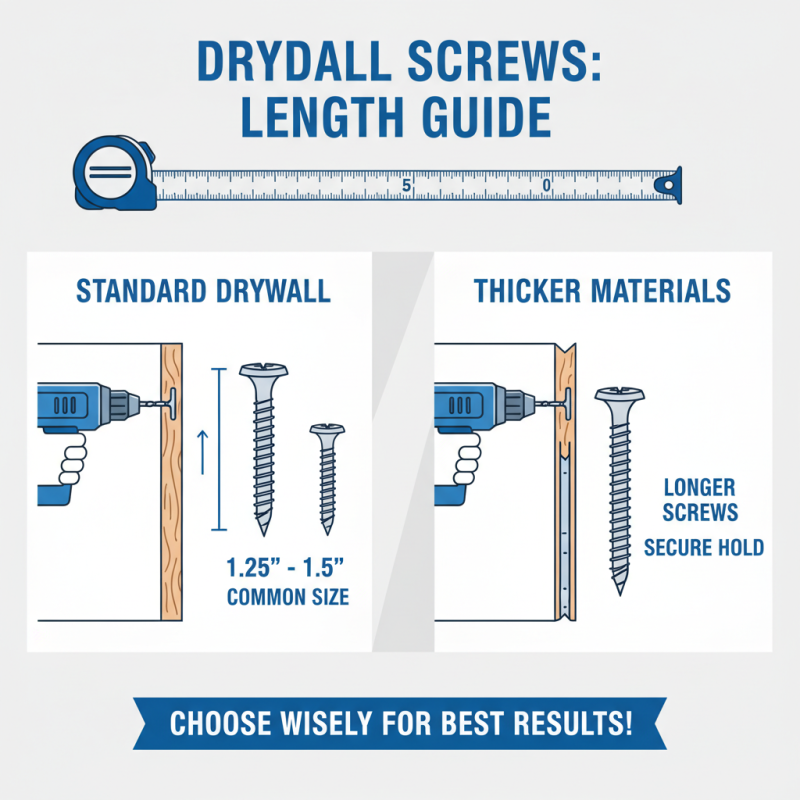

Tips: Always check the length of the screw before use. A common mistake is using screws that are too long or short. This can compromise the integrity of your installation.

Consider the coating of your screws. Most drywall screws are coated to prevent rust. Zinc-plated screws are suitable for interior applications. However, for areas prone to moisture, such as bathrooms, opt for screws with a special coating. They will last longer.

Tips: Remember to keep extra screws handy. You might misplace them or break a few during installation. It’s better to have some spare instead of making a trip to the hardware store.

Many overlook the proper torque when driving screws into drywall. Too much force can damage the board. You want a snug fit but not one that causes the paper to tear.

When choosing drywall screws, several key features can make a difference in your home improvement projects. Pay attention to the screw length. A common size is 1.25 to 1.5 inches for standard drywall thickness. Length affects how securely the screw will hold the drywall in place. For thicker materials, longer screws may be necessary.

The screw type is also important. Fine-thread screws work well for metal studs. Coarse-thread screws are better for wood. The head style matters too. Bugle heads help prevent tearing the drywall paper. This is crucial for maintaining integrity.

Additionally, consider the coating. Zinc-coated screws resist rust. This is vital in humid areas. However, some coatings may not stick well to paint. A reflective finish looks nice but may not be practical. Choose wisely based on your needs. Remember, each project can bring unique challenges, and adapting is key.

When tackling drywall projects, understanding industry standards is crucial. The length and gauge of drywall screws affect both their strength and compatibility. Typical drywall screws range from 1 inch to 3 inches in length. The most common gauges are 25 and 32, with 25-gauge screws being designed for standard thickness drywall.

A study from the National Association of Home Builders shows that using the right length is essential. Short screws may fail to hold, while long screws could penetrate too deeply, damaging insulation. It's essential to match screws with wall thickness. For example, half-inch drywall works best with 1.25-inch screws.

Tips: Always keep a variety of lengths on hand. This ensures you can adapt based on the project needs. Consider the screw's diameter too; thicker screws provide more holding power. Sometimes, over-relying on the strongest screws can lead to complications. Evaluate your project requirements often and adjust accordingly.

| Length (inches) | Gauge | Thread Type | Head Type | Material | Use Case |

|---|---|---|---|---|---|

| 1 1/4 | 6 | Coarse | Bugle | Steel | Standard drywall installation |

| 1 5/8 | 6 | Coarse | Bugle | Steel | Thicker drywall |

| 2 | 6 | Coarse | Flat | Galvanized Steel | Metal studs |

| 2 1/4 | 6 | Coarse | Bugle | Steel | Heavy-duty applications |

| 3 | 6 | Coarse | Bugle | Steel | High-density installation |

| 1 1/4 | 8 | Fine | Phosphated | Steel | Lightweight drywall |

| 2 1/2 | 8 | Fine | Bugle | Steel | Thick materials |

| 2 5/8 | 6 | Coarse | Flat | Steel | Especially for ceilings |

| 3 1/2 | 6 | Coarse | Bugle | Steel | Extra-strong support |

| 1 3/4 | 6 | Coarse | Bugle | Steel | Standard applications |

When installing drywall, the technique you use greatly affects how well the screws perform. Proper installation ensures a secure hold, preventing future issues like cracks or sagging. Consistent pressure during installation is key. It allows screws to grip firmly without damaging the drywall. Uneven pressure can lead to problems down the line.

Tips: Use a drill with a depth setter to prevent overdriving. This tool helps maintain the right depth. Aim for a flush surface, but don’t go too deep. You want the screw to sit just below the paper surface, not pierce through it.

Furthermore, consider the spacing and placement of your screws. Using too few can compromise structural integrity. Placing them too close can weaken the joint. Aim for a balanced approach to maximize strength and minimize any potential failure points. Pay attention to the type of screw you select. Some are designed for specific wall types or thicknesses. Taking the time to choose wisely will save you headaches later.