In the realm of construction, the efficient assembly of materials is crucial, and threaded rivets play a significant role in this process. Threaded rivets, known for their unique design that allows for a strong mechanical connection, have revolutionized how builders and engineers approach fastening in various applications. "Threaded rivets provide a level of strength and reliability that traditional fastening methods often lack," says Dr. Emily Hughes, a leading expert in structural engineering and fastener technology. Her insights highlight the importance of this innovative fastening solution in modern construction practices.

As the construction industry continues to evolve, the demand for robust and adaptable fastening solutions is greater than ever. Threaded rivets not only offer superior tensile strength but also allow for easy disassembly and reassembly, making them ideal for projects that require flexibility over time. From buildings to bridges, their impact is felt across various sectors, ensuring structural integrity and longevity. This article will delve deeper into what threaded rivets are, exploring their functionality and diverse applications, while also examining the advantages they provide to engineers and contractors alike.

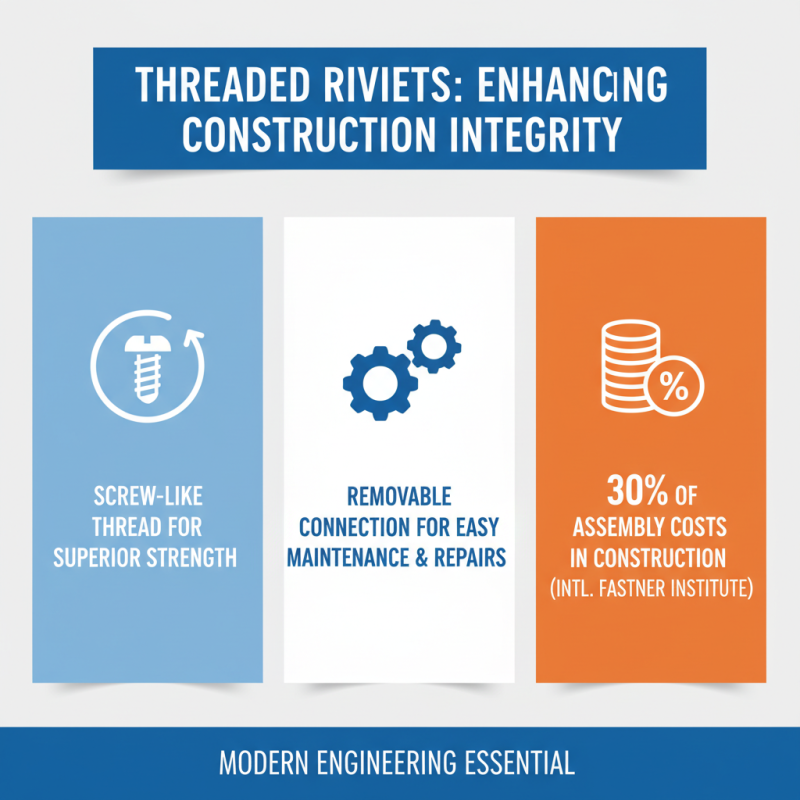

Threaded rivets, a specialized type of fastener, are increasingly recognized for their capacity to enhance structural integrity in construction projects. Unlike traditional rivets, which are solid and rely on the deformation of material to secure two or more components, threaded rivets feature a screw-like thread along their shaft. This design allows for additional strength and the ability to create a removable connection, which can be crucial for maintenance and repairs. According to the International Fastener Institute, fasteners like threaded rivets account for an estimated 30% of all assembly costs in construction, underscoring their importance in modern engineering practices.

In construction applications, threaded rivets are primarily used in conjunction with various materials, including metal, composite, and even some polymers. They not only facilitate effective load distribution but also cater to the increasing demand for lightweight yet robust assembly techniques. A recent report from the Structural Engineering Institute noted that the use of advanced fasteners, including threaded rivets, has seen a surge of up to 25% in specific sectors such as aerospace and automotive construction, reflecting the industry's ongoing push for innovations that enhance efficiency and reduce material waste. As construction methods evolve, the versatility and reliability of threaded rivets positions them as a critical component in the future of building practices.

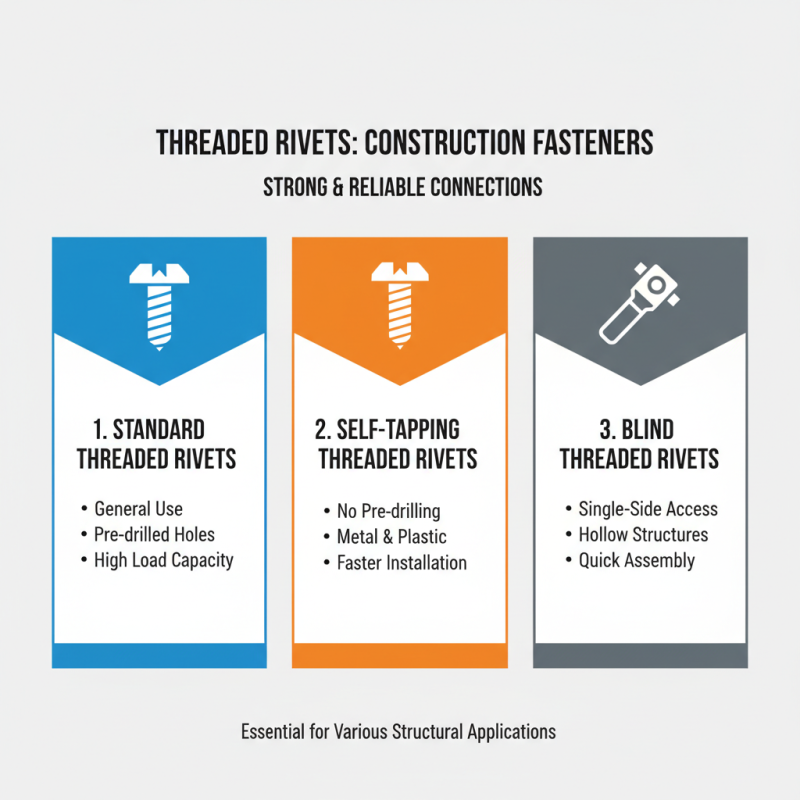

Threaded rivets are essential fasteners in the construction industry, designed to provide strong and reliable connections in various structural applications. The primary types of threaded rivets used in construction include standard threaded rivets, self-tapping threaded rivets, and blind threaded rivets. Each type serves a distinct purpose and comes with unique advantages, making them suitable for different construction environments.

Standard threaded rivets are equipped with external threads, allowing them to be paired with nuts or tapped holes. This type is commonly used in steel construction and structural assemblies, providing a solid connection that can withstand significant loads. Self-tapping threaded rivets, on the other hand, feature sharp threads that can create their own mating threads within the material they are inserted into. This feature is particularly useful for applications where access to the backside of the workpiece is limited. Lastly, blind threaded rivets offer a solution for situations where only one side of the material is accessible. They are designed to expand and grip the inside of the material as they are installed, making them ideal for thin sheets or applications where traditional fastening would be challenging.

Each type of threaded rivet contributes to the durability and strength of the construction, ensuring that critical structural elements are secure and reliable over time. Understanding the specific applications and benefits of these different types can help construction professionals choose the right fasteners for their projects, enhancing overall structural integrity.

Threaded rivets are a versatile fastening solution widely used in construction, offering several advantages that significantly enhance structural integrity and performance. One major benefit of using threaded rivets is their ability to provide strong, secure connections that can resist high levels of stress and vibration. This makes them particularly suitable for applications in high-load environments, such as bridges and commercial buildings. Their design also allows for easy disassembly, which can be crucial in construction projects that require maintenance or modifications over time.

Additionally, threaded rivets contribute to a streamlined construction process. They can be installed quickly and efficiently, reducing labor time and overall costs. The use of pre-drilled holes ensures precise alignment during installation, minimizing the risk of material damage. This efficiency can be a game-changer in project timelines, making threaded rivets an optimal choice for contractors looking to optimize workflow.

**Tips:** When selecting threaded rivets for your project, consider the load requirements and environmental factors, such as corrosion resistance. Always ensure that you have the correct tools for installation, as improper application can compromise the joint's strength. Lastly, keep in mind the future accessibility of the riveted joints for potential repairs or modifications.

| Dimension | Material | Application | Advantages |

|---|---|---|---|

| M6 | Steel | Structural Steel Connections | High Load-bearing Capacity |

| M8 | Aluminum | Aerospace Components | Corrosion Resistance |

| M10 | Stainless Steel | Marine Structures | Durability and Strength |

| M12 | Carbon Steel | Bridges and Overpasses | Cost-Effective Solution |

Threaded rivets are an essential component in construction, providing robust fastening solutions for various building materials. Installation methods for threaded rivets typically include inserting the rivet into pre-drilled holes in the materials to be joined. Once positioned, a specialized tool is used to engage the rivet's threaded shaft, allowing it to expand and create a secure connection. This method ensures a tight fit, making it ideal for applications requiring high strength and durability.

Another common installation technique involves using a nut to secure the threaded rivet in place. After the rivet is inserted, a nut is threaded onto the protruding end, tightening it to achieve the desired clamping force. This approach not only enhances the strength of the joint but also allows for easy disassembly when necessary. Adequate torque settings during installation are vital to ensure the integrity of the connection, preventing issues such as loosening or structural failure over time.

Threaded rivets are a crucial component in various construction projects, particularly noted for their ability to create strong, durable connections between structural elements. They are commonly used in applications where high strength and resistance to shear and tension forces are essential. According to a report from the International Journal of Engineering Research and Applications, the use of threaded rivets in building structural frameworks has increased by approximately 25% over the past decade, highlighting their growing importance in modern construction.

Among the prominent applications of threaded rivets, they are often employed in steel structures, bridges, and automotive assembly due to their excellent load-bearing capabilities. In the construction of high-rise buildings, threaded rivets facilitate the secure fastening of steel beams and columns, ensuring structural integrity while reducing overall construction time. Additionally, a study published by the American Institute of Steel Construction suggests that the proper use of threaded rivets can improve the efficiency of a building project by minimizing labor costs and time delays associated with traditional fastening methods.

Moreover, threaded rivets play a significant role in modular construction, where prefabricated components are assembled on-site. Their reliance on a threaded fastening mechanism allows for easier disassembly and reassembly, making them ideal for temporary structures and renovations. Industry experts estimate that the application of threaded rivets in modular building projects can lead to a 15% reduction in construction time, thereby streamlining workflows and enhancing project productivity.