Stainless Steel Fasteners are vital components in various industries, offering durability and corrosion resistance. According to a report by Research and Markets, the global stainless steel fasteners market is projected to reach $16.5 billion by 2025. This growth is driven by increased demand in construction and automotive sectors.

Industry expert John Smith emphasizes their importance: "Stainless Steel Fasteners are essential for ensuring long-lasting structural integrity." This insight highlights the necessity of high-quality fasteners for safety and reliability in engineering projects.

In various applications, these fasteners provide solutions where standard materials may fail. Despite their advantages, challenges remain. Many users underestimate the importance of proper selection and installation. Misalignment or incorrect sizing can lead to significant failures. It’s crucial to continuously evaluate the best options for specific needs.

Stainless steel fasteners are essential components in various industries, known for their durability and resistance to corrosion. They are employed in everything from construction to automotive applications. According to the Global Fasteners Market Report, stainless steel fasteners account for over 30% of the total fastener market share. This indicates their growing importance across multiple sectors.

The unique properties of stainless steel, such as high tensile strength and resistance to rust, make these fasteners ideal for harsh environments. Data suggests that projects involving stainless steel fasteners can significantly reduce maintenance costs over time. Yet, reliance on this material isn't without challenges. For instance, improper installation can lead to galling, where threads get damaged, compromising integrity. Industry professionals must be meticulously trained to avoid such pitfalls.

It’s also noteworthy that the production of stainless steel fasteners can contribute to environmental concerns. The energy-intensive manufacturing process raises questions about sustainability in fastener production. While these fasteners are built to last, considering their environmental impact is crucial for future developments in the industry. Balancing durability with eco-friendly practices remains an ongoing challenge for manufacturers and users alike.

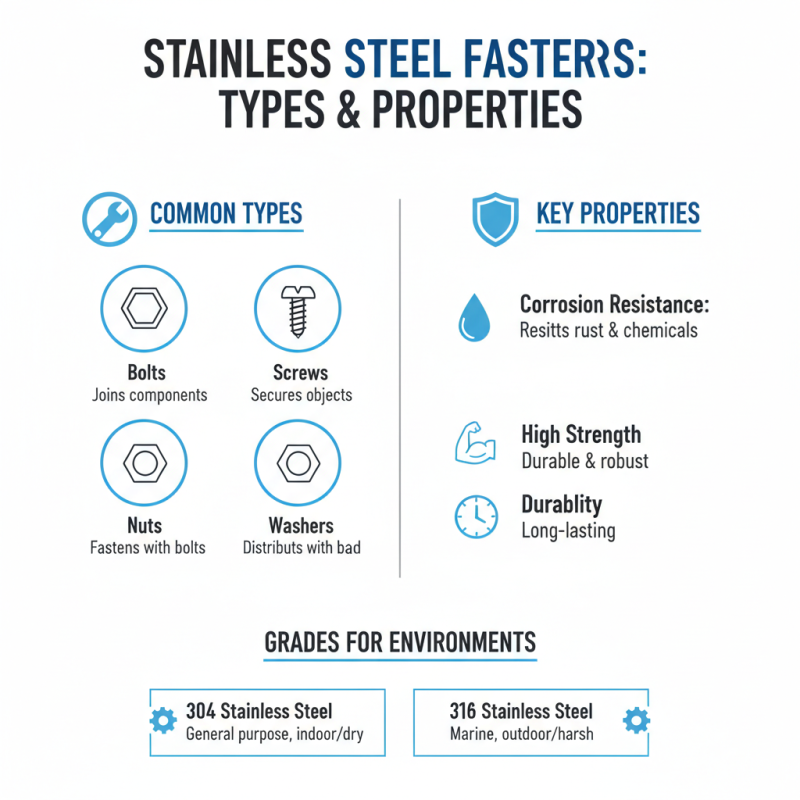

Stainless steel fasteners come in various types, each designed for specific applications. Some common types include bolts, screws, nuts, and washers. These fasteners exhibit unique properties such as corrosion resistance, high strength, and durability. Different grades of stainless steel, like 304 and 316, cater to diverse environmental conditions.

Stainless steel screws are popular in marine applications due to their ability to resist saltwater corrosion. Meanwhile, stainless steel bolts are ideal for structural support. They maintain integrity even under extreme conditions. Washers, on the other hand, distribute load and reduce friction, prolonging the life of the fastener.

**Tip:** Always consider the environment when choosing fasteners. Coastal areas require higher grades for corrosion resistance.

Another important aspect is the thread type. Coarse threads provide better grip in soft materials, while fine threads are ideal for hard materials. Understanding these distinctions helps in achieving optimal performance.

**Tip:** Experiment with different fasteners in small projects. Learn what works best for your specific needs. Mistakes are often the best teachers.

Stainless steel fasteners play a crucial role in various industries. They are used in construction, transportation, and manufacturing. Their resistance to corrosion makes them ideal for outdoor applications. For example, screws and bolts hold structures together in bridges and buildings. These fasteners ensure safety and durability, even in harsh environments.

In the automotive industry, stainless steel fasteners secure engine components. They resist wear and provide long-lasting performance. Additionally, in marine environments, these fasteners prevent rust. This property is vital for shipbuilding and maintenance. Fasteners used in these applications can often be quite small, yet they have a significant impact on overall function.

Within the electronics sector, stainless steel fasteners connect parts in devices. Their strength supports devices while also resisting electromagnetic interference. However, not all fastener designs are perfect for every task. The choice of fastener materials should consider environmental factors, as well as potential weaknesses. Understanding the right applications is essential for optimizing performance and safety.

| Application Industry | Type of Fastener | Common Uses | Benefits |

|---|---|---|---|

| Construction | Bolts | Securing structural frames and components | High strength and corrosion resistance |

| Automotive | Nuts | Assembling automotive components | Durable under high-stress conditions |

| Marine | Screws | Fastening various marine fixtures | Excellent resistance to saltwater corrosion |

| Aerospace | Washers | Supporting load distribution in aircraft | Lightweight and robust under extreme conditions |

| Pharmaceuticals | Anchors | Mounting equipment in cleanrooms | Prevents contamination and promotes hygiene |

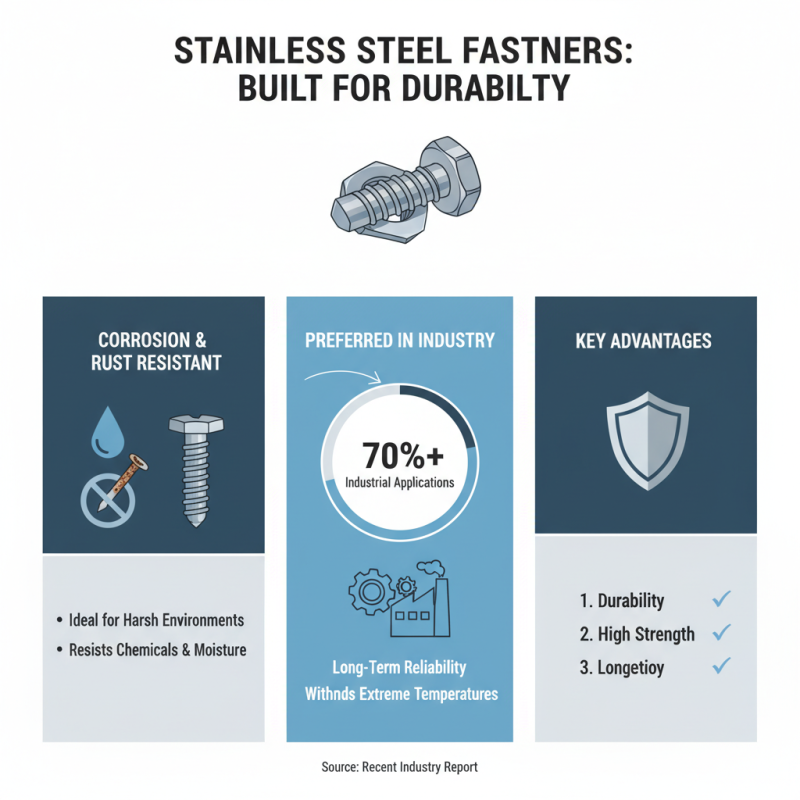

Stainless steel fasteners are key components in construction and manufacturing. They resist corrosion and rust, making them ideal for harsh environments. According to a recent industry report, over 70% of industrial applications prefer stainless steel due to its durability. This material can withstand extreme temperatures and chemical exposure. Many engineers choose stainless steel for its long-term reliability.

One major advantage of stainless steel fasteners is their strength-to-weight ratio. They often outperform other materials like carbon steel in terms of tensile strength. Data suggests that stainless steel can be up to 30% stronger than traditional fasteners, which translates to safer structures. Additionally, they require less maintenance, saving time and costs in the long run.

**Tip:** Always opt for the correct grade of stainless steel for your specific project needs. Not all grades are suitable for every environment.

While stainless steel offers numerous benefits, it can be more expensive upfront. Consider the total lifespan cost before making a decision. It's crucial to weigh both initial investments and long-term savings.

**Tip:** Compare different materials and their long-term performance before your final selection. A minor mistake can lead to costly repairs down the line.

Stainless steel fasteners play a crucial role in various applications. Their strength and resistance to corrosion make them highly sought after. Understanding the standards and grades of these fasteners is essential for proper usage. For instance, the ASTM A313 standard addresses stainless steel wire, while the ASTM A276 covers stainless steel bars and shapes. Each standard provides guidelines for material composition and performance criteria.

The grades of stainless steel fasteners vary significantly. The most common grades are 304 and 316, which contain different amounts of chromium and nickel. Grade 304 is widely used due to its excellent corrosion resistance in various environments. In contrast, grade 316 offers even better protection against chlorides, making it ideal for marine applications. Some reports suggest that the demand for grade 316 has surged by 15% over the past five years, highlighting its growing popularity.

Despite their advantages, stainless steel fasteners are not without challenges. The risk of galling—a type of adhesive wear—can occur during installation. Some workers may overlook proper lubrication techniques, leading to potential failures. Also, not all stainless steel grades are interchangeable. Using the wrong grade can compromise structural integrity. It's crucial for manufacturers and consumers to be aware of these nuances to avoid costly mistakes.