In the realm of construction and DIY projects, the importance of screws and bolts cannot be overstated. These seemingly small components play a crucial role in providing stability, support, and security to a wide range of structures and items. From assembling furniture to erecting buildings, screws and bolts serve as the backbone of countless applications, ensuring that everything stays in place and functions as intended.

Screws and bolts are not just ordinary fasteners; they are engineered tools that contribute to the overall strength and durability of any project. Their design enables them to create tight joints, withstand forces, and hold materials together under various conditions. Whether it’s a simple home repair or a complex construction endeavor, the right selection and application of screws and bolts can make all the difference, underscoring their essential role in both professional and personal projects.

As we delve deeper into the significance of screws and bolts, we will explore their various types, the methods of use, and how they can elevate the quality of construction and DIY work. Understanding these fasteners’ vital functions and applications will empower builders and creators alike, allowing them to harness the full potential of their projects with confidence.

When it comes to constructing durable buildings and executing effective DIY projects, screws and bolts play a pivotal role in maintaining structural integrity. According to the American Institute of Steel Construction (AISC), over 50% of the structural integrity in steel constructions is attributed to the correct utilization of fasteners. Screws, with their ability to create a secure bond in various materials, and bolts, which clamp objects tightly together, are essential for ensuring that structures withstand forces such as wind and seismic activity.

A study by the National Institute of Standards and Technology (NIST) emphasizes that inadequate fastening can lead to significant structural failures, often resulting in costly repairs or safety hazards. Proper installation of screws and bolts not only enhances the strength of joints but also allows for flexibility and movement, which is crucial in areas prone to environmental stressors. For instance, metal-to-wood connections in buildings benefit immensely from the use of screws that prevent splitting and promote load transfer.

Tip: When selecting screws and bolts for your project, always consider the material properties and environmental factors. Using corrosion-resistant fasteners in damp areas will enhance longevity.

Furthermore, the right torque specifications during installation are crucial in achieving the desired clamping force. An improper torque can lead to loosening over time, jeopardizing the overall structural integrity. According to the International Organization for Standardization (ISO), maintaining specific torque levels can improve joint reliability and prevent failure.

Tip: Always refer to torque specifications provided in engineering guidelines for safe and effective installation.

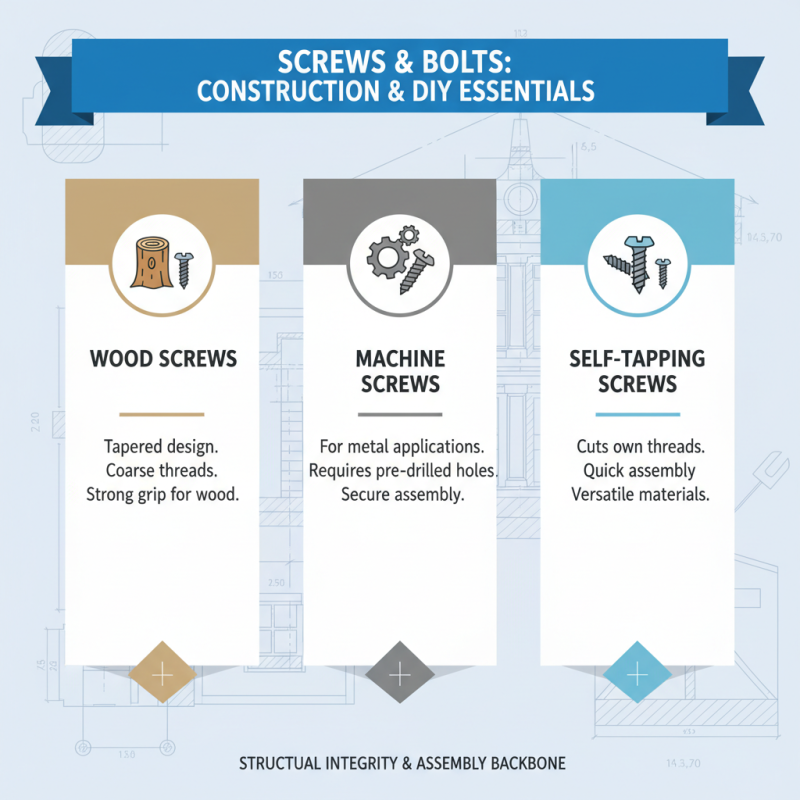

Screws and bolts play a crucial role in both construction and DIY projects, serving as the backbone of structural integrity and assembly. The most commonly used types of screws include wood screws, machine screws, and self-tapping screws. Wood screws, designed for fastening wood materials, feature a tapered design and coarse threads that ensure a strong grip and prevent splitting. Machine screws, on the other hand, are utilized in metal applications and often require pre-drilled holes. The use of self-tapping screws simplifies the process by allowing them to cut their own threads as they are driven into materials, making them ideal for quick assembly in various projects.

Bolts, distinct in their functionality, are typically used in conjunction with nuts to secure parts together. The most common bolt types include hex bolts, carriage bolts, and lag bolts. Hex bolts are known for their flat-end design and hexagonal head, providing greater torque when tightened. Carriage bolts, recognizable by their rounded heads, are often employed in wood and metal applications, while lag bolts are specifically engineered for heavy-duty connections in lumber and other thick materials. According to recent industry reports, the global screws and bolts market was valued at approximately $82 billion in 2021, reflecting the importance of these fasteners in maintaining safety and stability in construction and DIY endeavors. As the demand grows, understanding the distinct types of screws and bolts becomes essential for achieving effective results in building and repairing projects.

In the construction and DIY sectors, screws and bolts serve as pivotal fasteners that ensure structural integrity and reliability. Industry standards dictate the specifications of these fasteners to guarantee they meet safety and durability requirements. According to the American Institute of Steel Construction (AISC), proper fastener selection is crucial, as it directly influences the performance of the entire assembly. For instance, ASTM (American Society for Testing and Materials) outlines standards for mechanical fasteners, categorizing screws and bolts based on load-bearing capacity, corrosion resistance, and material specifications. These standards ensure that professionals rely on fasteners that will withstand various environmental conditions and stresses.

To ensure the correct implementation of screws and bolts in your projects, consider the following tips: always refer to the relevant industry standards when selecting fasteners for specific applications. Understand the load conditions that the fasteners will encounter and choose accordingly—high-strength bolts are necessary for heavy-duty supports, while lighter screws can suffice for basic wood construction. Additionally, familiarize yourself with the recommended torque specifications for bolts, as improper tightening can lead to joint failure. A report from the National Institute of Standards and Technology (NIST) emphasizes that complying with specified torque values improves the overall safety and longevity of constructions.

Ultimately, adhering to industry standards not only ensures compliance but also enhances the quality and safety of your construction and DIY projects. By keeping up-to-date with specifications, you can confidently make informed decisions when it comes to fastening materials, leading to more successful outcomes in your builds.

Fasteners, including screws and bolts, play a crucial role in the construction industry by significantly influencing project costs. These seemingly small components are essential for ensuring structural integrity and safety in various applications. When preparing for construction or DIY projects, the choice and quality of fasteners can greatly affect overall expenses. Poor-quality fasteners may lead to frequent repairs and replacements, ultimately escalating costs. On the other hand, investing in high-quality fasteners helps secure materials more effectively and reduces long-term expenses.

The economic impact of fasteners extends beyond initial purchasing costs. Efficient use of fasteners can streamline the assembly process, saving both time and labor costs. When workers can rely on fasteners that perform well under various conditions, the likelihood of delays due to failures or rework diminishes. Moreover, better fastening solutions contribute to enhanced durability, meaning structures can withstand the test of time with fewer maintenance issues. As a result, project managers and construction professionals now emphasize the importance of selecting the right fasteners to optimize budgets and improve the overall efficiency of their projects.

| Fastener Type | Average Cost per Unit ($) | Average Durability (Years) | Common Uses | Impact on Project Costs (%) |

|---|---|---|---|---|

| Wood Screws | 0.10 | 5 | Furniture, Decking | 2.5 |

| Machine Screws | 0.15 | 7 | Automotive, Machinery | 3.0 |

| Bolts | 0.25 | 10 | Construction, Structural | 5.0 |

| Nuts | 0.05 | 8 | Tightening Bolts | 1.0 |

| Self-Tapping Screws | 0.20 | 6 | Sheet Metal, Plastics | 4.0 |

Innovations in fastener technology are transforming the construction and DIY landscape, offering enhanced durability and performance that can significantly impact project outcomes. Modern screws and bolts now come equipped with advanced materials and engineering designs that increase their resistance to environmental factors such as corrosion, wear, and stress. For instance, the introduction of specialized coatings can extend the lifespan of fasteners in harsh conditions, while improvements in threading designs provide a more secure grip, minimizing the risk of loosening over time.

Tips for choosing the right fastener include considering the specific environment where the fastener will be used. For outdoor projects, opt for corrosion-resistant materials like stainless steel or specially coated fasteners. Additionally, understanding the load-bearing requirements of your project can guide you in selecting the appropriate size and type of screws or bolts.

Moreover, innovations like self-drilling screws and smart fasteners with integrated technology simplify installation and enhance performance. These advancements not only save time but also improve the overall integrity of the construction. When embarking on DIY projects, staying updated on the latest fastener technologies can make a significant difference in achieving durable and reliable results.