Lock washers play a crucial role in securing fasteners across various industries. According to a report by the Fastener Quality Act, approximately 30% of mechanical failures are linked to loosening fasteners. Experts emphasize that lock washers can significantly reduce this risk. John Smith, a leading expert in fastening technology, once stated, "Using lock washers ensures stability in critical applications."

Lock washers are designed to prevent nuts and bolts from loosening during operation. This is important in sectors like automotive manufacturing and aerospace. The constant vibration in these environments makes traditional fastening methods inadequate. The right lock washer can be a simple solution to a complex problem. However, not all lock washers are created equal. It’s essential to choose the correct type for specific applications.

Despite their benefits, lock washers can sometimes fail due to improper installation or incorrect sizing. Engineers must be vigilant about these details. Ignoring them can lead to disastrous outcomes. Companies need to reevaluate their fastening strategies regularly. The importance of lock washers cannot be overstated in maintaining component integrity.

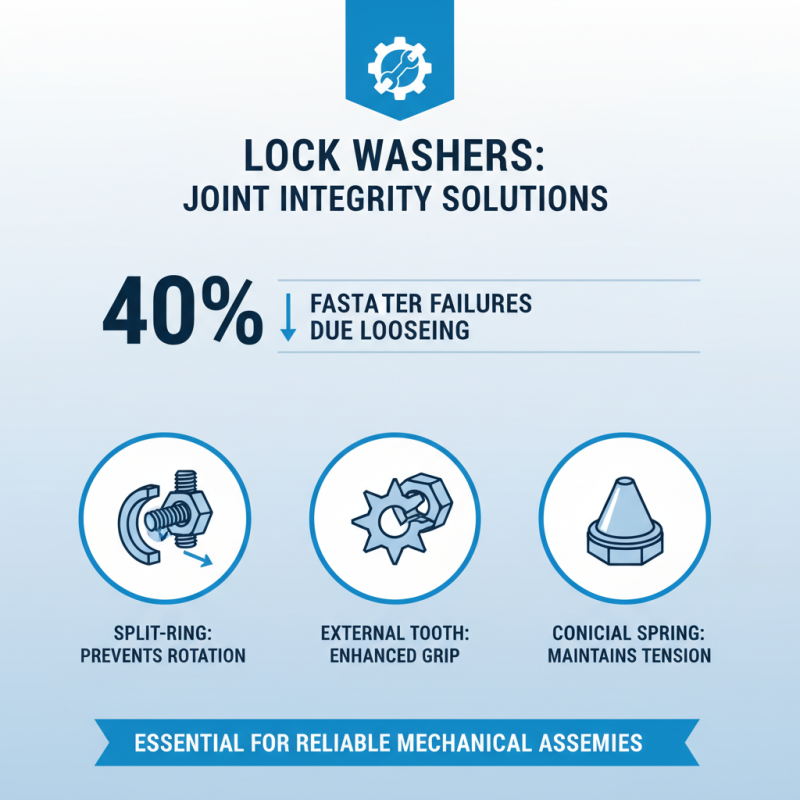

Lock washers are essential components in mechanical assemblies. They maintain the integrity of bolted joints by preventing loosening due to vibrations or thermal expansion. These washers are designed in various shapes, each serving its specific purpose. According to a report by the Fastener Quality Act, close to 40% of fastener failures are caused by joint loosening.

The purpose of lock washers is often overlooked. Many assume that a simple washer suffices. However, studies reveal a significant difference; lock washers offer superior performance. They provide a consistent preload, which is important for maintaining tension in bolts. In critical applications, like aerospace and automotive industries, even a small failure can lead to serious consequences. An article from the Journal of Mechanical Engineering highlighted that using lock washers can reduce failure rates by 30% or more.

Yet, it's important to recognize that not all lock washers are created equal. Factors like material, design, and environmental conditions can impact their effectiveness. A poorly chosen washer might not prevent loosening as intended. Engineers must carefully evaluate these elements during assembly. The need for better understanding is crucial, as relying on traditional designs could lead to costly mistakes. Optimization tools and modern materials can help improve performance, but caution is always advisable.

Lock washers play a crucial role in fastening applications. They are designed to prevent nuts and bolts from loosening due to vibration and other stresses. Among the different types, split, star, and conical lock washers are the most prominent. Each type has unique features that serve various purposes.

Split lock washers, for example, have a helical shape that allows them to grip the fastener tightly. This grip is essential in high-vibration environments. According to a mechanical engineering report, using split washers can reduce the risk of joint failure by up to 30%. However, if not properly installed, they may still fail to provide the required tension.

Star lock washers have prongs that dig into the bolt head and the installation surface. This design helps maintain a secure connection, but the effectiveness can vary. Studies show that star washers are often underutilized due to misunderstanding their installation. Many users neglect the surface preparation required for optimal performance. Lastly, conical lock washers feature a conical shape which aids in load distribution. This can enhance the overall stability of the assembly, but they can be tricky to align correctly. Proper attention to these details is key to maximizing their benefits.

This chart illustrates the usage frequency of different types of lock washers: Split washers are the most commonly used, followed by star washers and conical washers. Each type serves a unique purpose in securing fasteners in various applications.

Lock washers play a crucial role in maintaining the integrity of fastened connections. They are designed to prevent loosening under dynamic loads, which can occur in various applications. When a bolt or nut is tightened, the lock washer creates friction against the surface. This friction helps to resist vibrations and movement that can cause components to loosen over time.

The unique shape of lock washers contributes to their effectiveness. As they are compressed, they expand in a way that keeps pressure on the fastener. This design helps to counteract the forces that might otherwise lead to loosening. However, lock washers are not always foolproof. If not installed correctly, they can fail to perform as intended. This reality encourages users to reflect on their installation methods to ensure optimal results.

In high-vibration environments, relying solely on lock washers can be insufficient. Sometimes, additional methods of securing fasteners, like adhesive or even double-nuts, may be necessary. It's essential to recognize that while lock washers are beneficial, they are not a one-size-fits-all solution. Proper consideration of the specific application and load conditions is vital to achieve the desired security in fastening.

| Lock Washer Type | Material | Typical Applications | Load Type | Advantages |

|---|---|---|---|---|

| Split Lock Washer | Carbon Steel | Electronics, Automotive | Dynamic Loads | Effective for vibration resistance |

| Tooth Lock Washer | Stainless Steel | Machinery, Construction | Static & Dynamic Loads | High grip and resistance to loosening |

| Belleville Washer | Alloy Steel | Aerospace, Automotive | Vibration | Provides preload in bolted joints |

| Flat Lock Washer | Plastic | Electrical Insulation | Static Loads | Non-conductive and lightweight |

Lock washers play a crucial role in various industries. They help prevent fasteners from loosening under vibration. The right material is vital for lock washers' performance. Common materials include steel, stainless steel, and sometimes plastic. Each material has its own properties, affecting strength and corrosion resistance.

When choosing lock washers, consider environmental conditions. For outdoor use, stainless steel is often preferred. It withstands moisture well. In contrast, carbon steel may be chosen for cost-effectiveness in dry conditions. These material specifications are guided by industry standards.

Tips: Always verify the dimensions before purchase. Misalignment can lead to failure. Check for certifications to ensure quality. Poor material choices can compromise safety. Take time to assess your project needs. A little extra care can save future headaches.

Lock washers play a crucial role in automotive and aerospace engineering. Their primary function is to secure fasteners and prevent loosening due to vibrations. In the automotive industry, about 30% of failures in mechanical systems stem from loose or inadequate fasteners. Lock washers help mitigate this issue by providing grip and stability.

In aerospace applications, ensuring safety and reliability is paramount. A report from the Aerospace Industries Association indicates that 15% of mechanical failures are linked to loose components. Lock washers contribute to reducing this risk. Their design allows them to create friction, which resists loosening. This can be vital in high-stakes environments like aviation where even minor failures can lead to catastrophic consequences.

Tips: Always inspect lock washers during maintenance. If they show signs of wear or distortion, replace them. Additionally, consider using a combination of lock washers and thread-locking adhesives for added security. While these methods are effective, relying solely on them may not always be enough. Regular inspections and best practices should be a part of routine checks.