Heavy lifting is a crucial aspect in various industries, from construction to shipping. To ensure safety and efficiency, the use of Lifting Eye Bolts has become vital. According to industry reports, improper lifting methods account for nearly 20% of workplace injuries. Using Lifting Eye Bolts can minimize these risks dramatically.

These specialized bolts are designed to provide secure lifting points. In fact, they can handle loads exceeding several tons. A recent study showed that proper use of Lifting Eye Bolts can increase lifting efficiency by up to 30%. This statistic highlights the importance of selecting the right equipment for heavy lifting tasks.

However, it's essential to acknowledge that not all Lifting Eye Bolts are created equal. Misuse or substandard products can lead to catastrophic failures. Regular inspections are necessary. Industry guidelines recommend a full evaluation before each use. Choosing quality Lifting Eye Bolts is crucial for both safety and performance.

Lifting eye bolts play a crucial role in heavy lifting applications. They are designed to provide a secure connection point for lifting slings and chains. This ensures safety and stability during operations. According to a recent industry report, using properly rated lifting eye bolts can reduce accident rates by up to 30%. That’s significant, especially in industries where heavy lifting is routine.

One of the key advantages of lifting eye bolts is their versatility. They can be installed in various materials, including steel and concrete. This adaptability makes them ideal for construction sites, warehouses, and factories. The right installation ensures that they can handle loads exceeding several tons. However, it’s essential to note that improper installation can lead to failures. Regular inspections and compliance with load ratings are necessary.

Weight distribution is another important factor. Data indicates that poorly distributed loads increase the likelihood of equipment failures. Using lifting eye bolts helps mitigate this risk. Their design assists in evenly distributing the weight across multiple points. This allows for safer lifting and maneuvering of heavy items. Yet, even with the best equipment, oversight can happen. Continuous training and awareness are pivotal for maintaining safety standards.

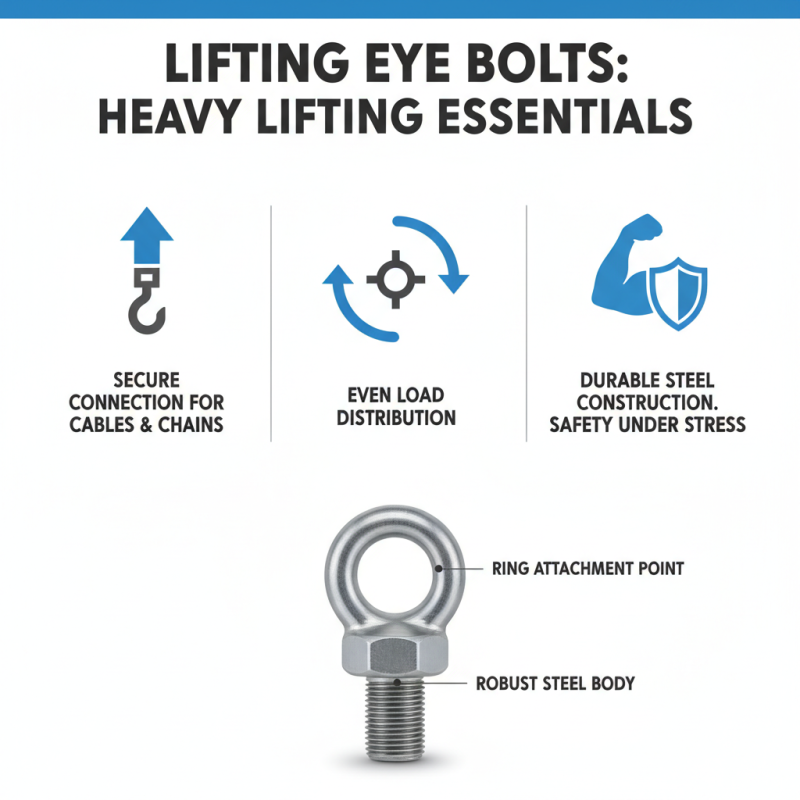

Lifting eye bolts are essential for heavy lifting applications. Their robust design features a ring on top, allowing secure connection to cables or chains. This configuration helps evenly distribute loads during lifting. The steel construction ensures durability, resilience, and safety even under stress.

It’s crucial to understand the load ratings before using them. Each eye bolt has a specific capacity, and exceeding it can lead to failure. Choose the right size and type for your project. Sometimes, users overlook the importance of proper installation. Misalignment can weaken the lifting point and cause accidents. Regular inspection is vital to ensure functionality and safety.

Lifting eye bolts can sometimes face wear and tear. Corrosion or deformation can compromise their integrity. Addressing these issues requires vigilance. Workers should be trained on what to check. Mistakes happen, but understanding the functionality can prevent accidents. Developing a habit of reviewing practices promotes safe and efficient lifting processes.

When using lifting eye bolts for heavy loads, safety should always be the priority. According to a report by the Occupational Safety and Health Administration (OSHA), improper rigging is a leading cause of accidents in construction. Eye bolts can be a reliable choice, but they also require proper usage. Many operators overlook the need for thorough inspection before use. Cracks or deformation in the bolts can lead to disastrous failures.

Load limits are another critical point. Many lifting eye bolts are rated for specific loads. However, these ratings depend on angles of lift and other factors. The International Organization for Standardization (ISO) states that the angle of the pull should ideally be within 10 to 15 degrees of vertical to avoid undue stress. This means that operators need to be mindful and double-check their rigging plan.

Lastly, it's not just about choosing the right eye bolt. Proper training is essential. A study from the National Safety Council suggests that 70 percent of rigging errors stem from inadequate training. Workers need to understand how to calculate loads, select equipment, and execute lifts correctly. Relying solely on equipment can lead to dangerous oversights.

| Load Weight (lbs) | Bolt Size (inches) | Maximum Safe Load (lbs) | Material | Safety Factor |

|---|---|---|---|---|

| 1500 | 1 | 3000 | Steel | 2:1 |

| 3000 | 1.5 | 6000 | Stainless Steel | 2:1 |

| 4500 | 2 | 9000 | Alloy Steel | 2:1 |

| 6000 | 2.5 | 12000 | Carbon Steel | 2:1 |

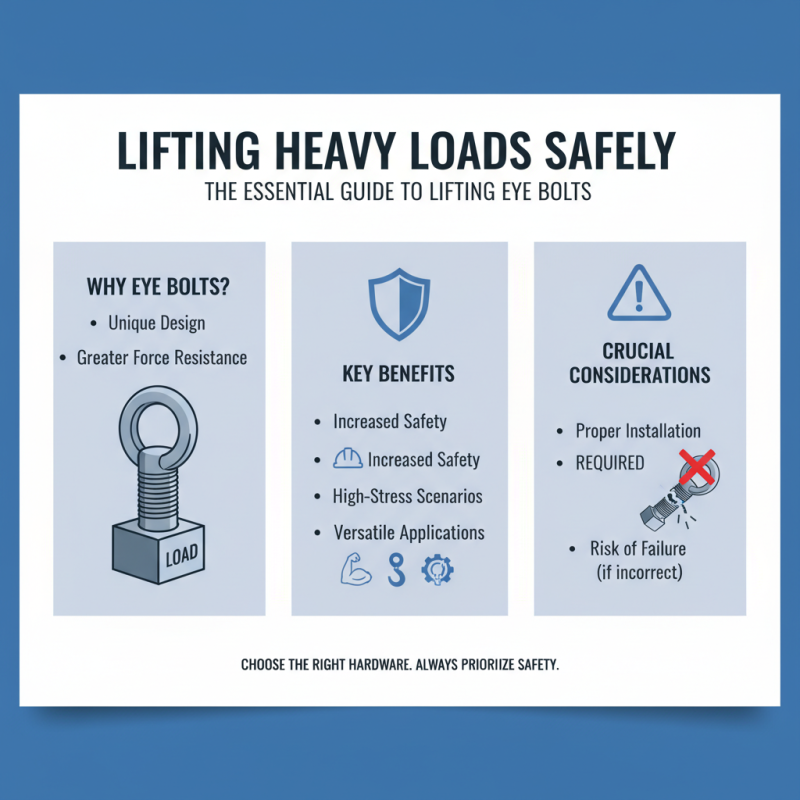

When lifting heavy loads, choosing the right hardware is crucial. Lifting eye bolts stand out for their unique design. Unlike standard hooks or chains, eye bolts are built to withstand greater forces. They allow for secure attachment points, making them ideal for various applications. This design provides added safety when dealing with high-stress scenarios. However, improper installation can lead to failures, which is something to consider.

Comparing lifting eye bolts with other hardware options reveals their advantages. Chains may slip or fail under heavy loads, while hooks lack stability. Conversely, eye bolts can handle significant weight when properly installed. While they may require careful planning, the benefits often outweigh the challenges. Still, it’s vital to assess the conditions and use the correct size for the job. Neglect can lead to accidents, and that’s a reality worth reflecting on.

In the realm of heavy lifting, attention to detail is key. Lifting eye bolts offer a reliable solution, but they come with a responsibility. Regular inspections and maintenance are a must. With careful consideration and regular checks, they can serve as a dependable choice for lifting tasks. The balance between strength and proper usage is essential.

When working with lifting eye bolts, proper installation and usage are crucial for safety. Start by selecting the right eye bolt for your load. Factors like weight, angle, and environment matter. Ensure the bolt is rated for the intended load. This ensures maximum safety and efficiency.

Installation requires careful attention. The eye bolt should be threaded into a stable and secure structure. Check for any signs of wear or damage before use. Poorly installed or damaged bolts can lead to failure. It’s essential to confirm that the load is evenly distributed. Uneven loads can cause unexpected stresses. Always utilize appropriate hardware when attaching the eye bolt.

While lifting, observe your surroundings. Be mindful of obstacles and potential hazards. Engaging a spotter can increase safety during heavy lifts. There may be moments when you feel rushed. Avoid cutting corners in these critical situations. Always double-check every connection. Reflecting on past experiences can help improve future practices. Remember, safety should never be compromised.