In the realm of modern manufacturing and assembly processes, the use of

Weld Nuts

has become increasingly prevalent due to their efficiency and reliability.

According to a recent report by the Industrial Fasteners Institute, approximately

25% of assembly operations

in automotive and heavy machinery industries now incorporate weld nuts to streamline

production and enhance structural integrity. This innovative fastening solution not

only reduces the need for secondary operations but also improves the strength-to-weight

ratio in assembled products. As designers seek to optimize construction methodologies

and cut down on production costs, understanding the incredible benefits of weld nuts

is essential. From simplifying assembly to enhancing overall performance, the advantages

they present are poised to transform project outcomes across various sectors, making

them an indispensable component for engineers and manufacturers alike.

In the realm of modern manufacturing and assembly processes, the use of

Weld Nuts

has become increasingly prevalent due to their efficiency and reliability.

According to a recent report by the Industrial Fasteners Institute, approximately

25% of assembly operations

in automotive and heavy machinery industries now incorporate weld nuts to streamline

production and enhance structural integrity. This innovative fastening solution not

only reduces the need for secondary operations but also improves the strength-to-weight

ratio in assembled products. As designers seek to optimize construction methodologies

and cut down on production costs, understanding the incredible benefits of weld nuts

is essential. From simplifying assembly to enhancing overall performance, the advantages

they present are poised to transform project outcomes across various sectors, making

them an indispensable component for engineers and manufacturers alike.

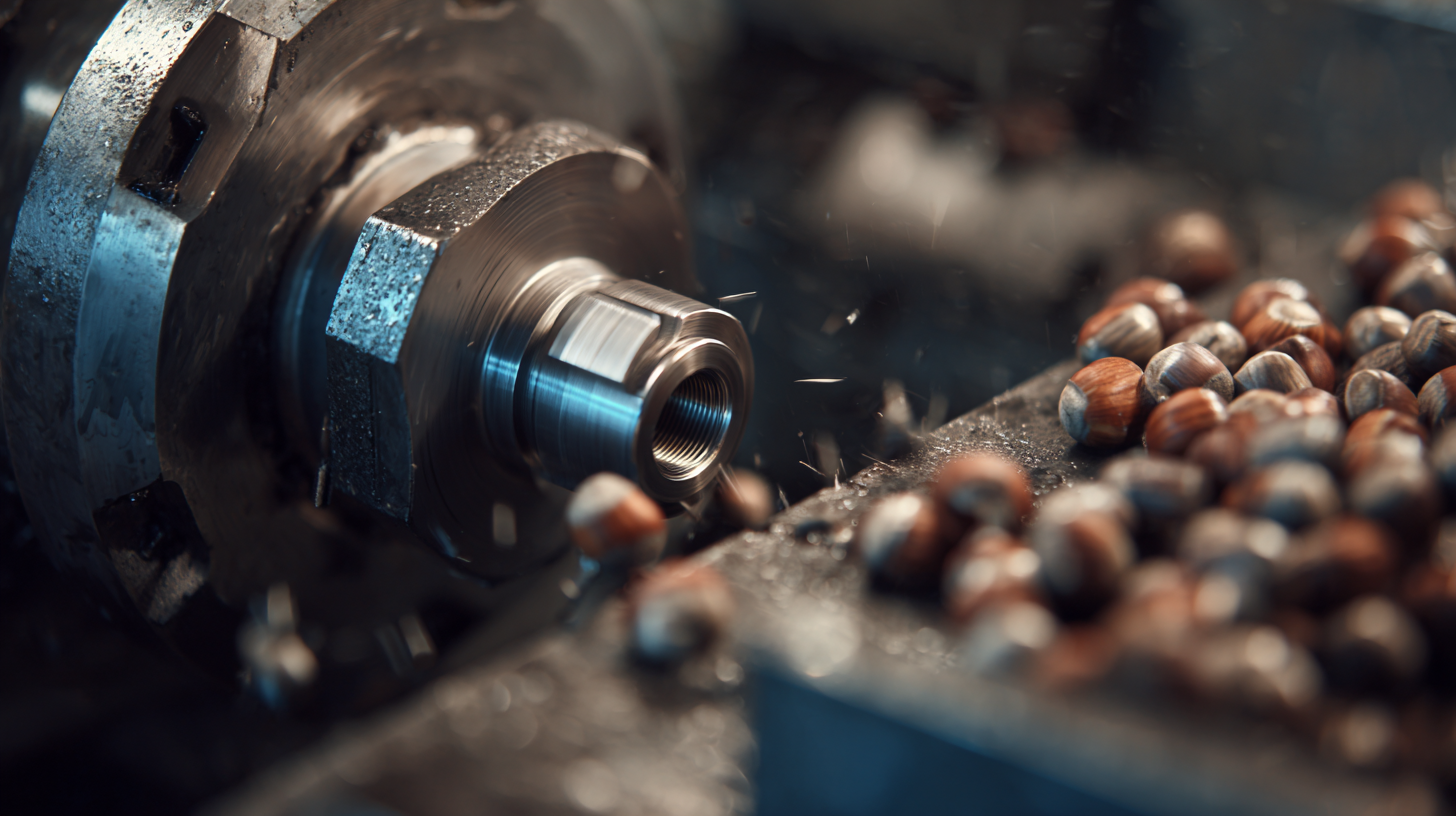

Weld nuts are specialized fasteners designed to be welded onto surfaces, providing a permanent mounting point for bolts in various applications. Unlike traditional nuts, which can loosen over time, weld nuts create a robust and secure connection that is less prone to vibration-induced failure. According to a report by the Industrial Fasteners Institute, the use of weld nuts can improve the integrity of assemblies, especially in high-stress environments, by minimizing the risk of loosening and offering reliable torque performance.

Weld nuts are specialized fasteners designed to be welded onto surfaces, providing a permanent mounting point for bolts in various applications. Unlike traditional nuts, which can loosen over time, weld nuts create a robust and secure connection that is less prone to vibration-induced failure. According to a report by the Industrial Fasteners Institute, the use of weld nuts can improve the integrity of assemblies, especially in high-stress environments, by minimizing the risk of loosening and offering reliable torque performance.

When incorporating weld nuts into your projects, consider these essential tips. First, ensure you select the right type of weld nut for your specific application; different geometries can provide better weld penetration and strength. Additionally, proper surface preparation is crucial—clean the area where the weld nut will be attached to avoid contamination that could weaken the weld. It’s also beneficial to adhere to recommended welding techniques, as improper methods can lead to poor mechanical performance.

Utilizing weld nuts can streamline your assembly process, as they eliminate the need for additional hardware, ultimately reducing assembly time by approximately 30%, as highlighted in a recent study by the Fastener Technology International. By understanding how weld nuts work and applying best practices, you can enhance the durability and efficiency of your projects.

Weld nuts are revolutionizing the way components are secured in various manufacturing processes, offering notable advantages across multiple applications. One of the most significant benefits is their ability to provide a strong, permanent fastening point directly within the material, which enhances structural integrity. According to a report by the American Welding Society, weld nuts can withstand extreme mechanical loads—up to 25% more than standard fasteners. This capability makes them ideal for automotive and aerospace industries, where safety and reliability are paramount.

Additionally, the installation of weld nuts can lead to space and weight savings in design. By reducing the need for additional hardware, manufacturers can streamline their assembly processes. A study by the Engineering Society of Detroit highlights that using weld nuts can decrease assembly times by an impressive 30%, which not only boosts productivity but also reduces labor costs.

**Tip:** When selecting weld nuts for your project, consider the material compatibility and environmental conditions they will face. Ensuring a perfect match can enhance performance and longevity.

**Tip:** Use automated welding facilities where possible, as they can minimize human error and further improve the precision of weld nut installations. Ultimately, this will elevate the quality of your final product.

When it comes to securing components in various projects, choosing the right fastener can significantly impact the overall efficiency and durability of your design. Weld nuts, as opposed to traditional fasteners, offer a unique set of advantages that are worth examining. While traditional fasteners often require extra components like washers and nuts for proper installation, weld nuts simplify the process by allowing direct welding to surfaces, which not only speeds up assembly but also provides a robust internal thread for bolted connections.

One of the key benefits of weld nuts is their ability to withstand high levels of stress and vibration. This makes them ideal for applications in automotive and heavy machinery where traditional fasteners may loosen over time. Additionally, weld nuts minimize the risk of cross-threading during assembly, leading to fewer failures and less downtime.

Tip: When using weld nuts, ensure that the surface is clean and free of contaminants to achieve the best weld quality. Also, consider the alloy type of the weld nut to match your project's material for improved compatibility. Using the right welding technique is crucial; for instance, a proper setup can enhance both the strength and appearance of the weld, contributing to a polished final product.

When it comes to maximizing the efficiency and durability of your projects, proper installation of weld nuts is crucial. One of the best practices is to ensure that the welding surface is clean and free of contaminants. This avoids issues such as poor weld penetration and weak joints. Before starting, inspect the weld nuts for any defects; damaged nuts can compromise the integrity of the entire assembly. It’s also advisable to use the correct welding parameters, including suitable current and voltage settings, to achieve optimal results.

Another key practice is to maintain consistent pressure during the welding process. This helps create a strong bond between the weld nut and the base material. Additionally, allowing the weld to cool slowly can prevent warping and maintain strength. After installation, performing visual inspections and, if necessary, non-destructive testing can identify potential issues before they become critical. By following these best practices, you can ensure that your weld nuts provide the reliable performance needed for your projects, enhancing overall effectiveness and longevity.

Weld nuts offer remarkable cost-effectiveness for various engineering projects, particularly in the long run. Their integration in manufacturing not only simplifies assembly but also enhances structural integrity, ultimately reducing operational costs. According to market analyses, utilizing weld nuts can lead to significant long-term savings by minimizing the need for additional fasteners and reducing assembly times. This efficiency translates into lower labor costs and improved productivity, making weld nuts a smart investment for project managers looking to optimize their budgets.

In sectors where reliability and performance are paramount, weld nuts serve as a dependable fastening solution, contributing to the lifespan of products and reducing maintenance expenses. For instance, the pool equipment market, projected to reach $13.81 billion in 2023 with a growth rate of 4.25% through 2031, can greatly benefit from adopting such cost-effective fastening solutions. By incorporating weld nuts in construction, manufacturers not only increase production efficiency but also cut down on expensive recalls and repairs, demonstrating their vital role in achieving sustainable savings over time.