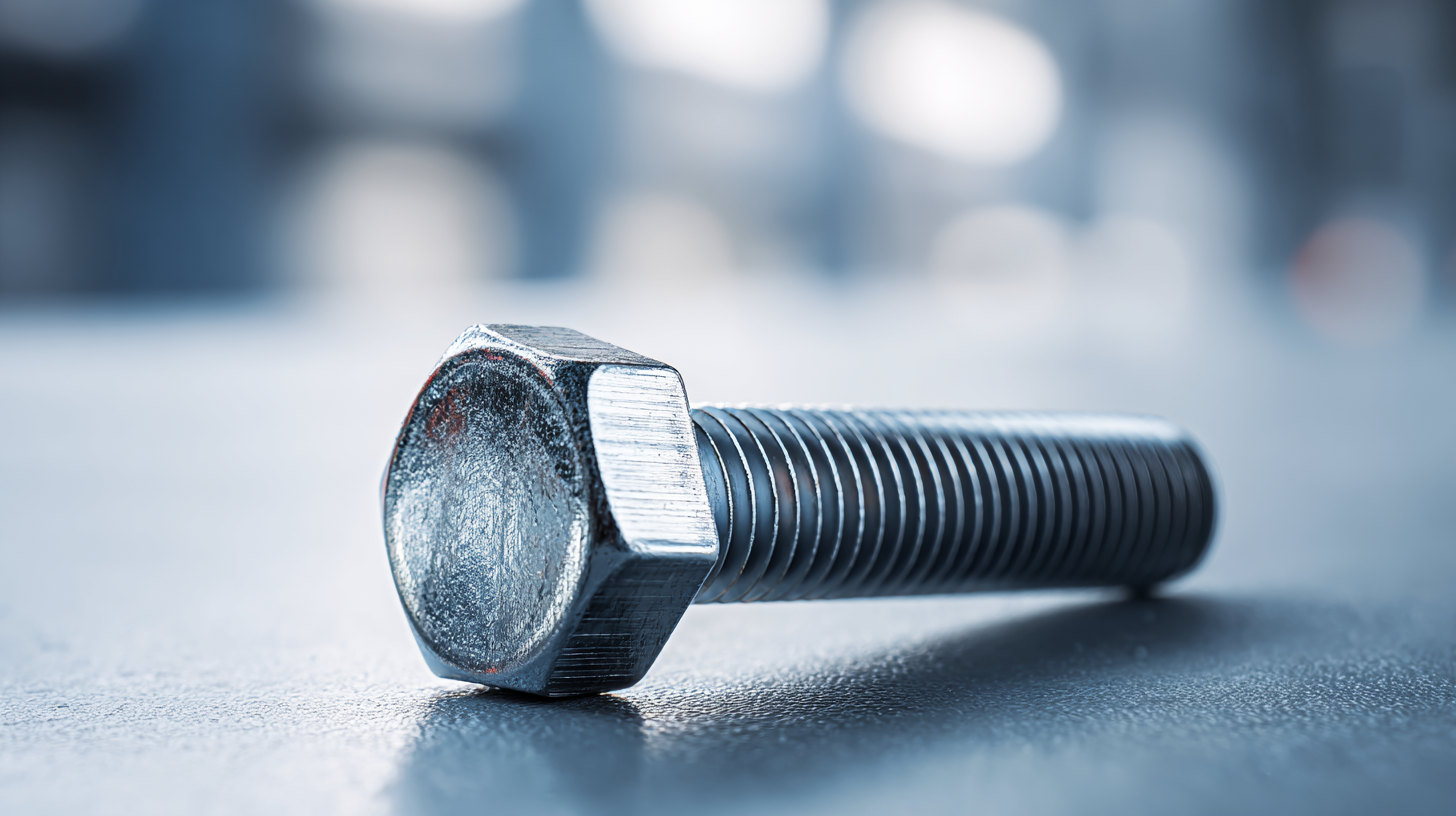

Hex head screws play a pivotal role in modern engineering applications, providing essential strength and reliability in a wide range of structures and machinery. According to a report by Grand View Research, the global fasteners market was valued at approximately $87 billion in 2021, with hex head screws accounting for a substantial share due to their versatility and performance characteristics. These fasteners are particularly favored in construction, automotive, and aerospace industries, where precise torque and resistance to vibrations are critical. The unique design of hex head screws allows for efficient installation and higher load-bearing capacities, making them indispensable in various applications. As engineering standards continue to evolve, the demand for high-quality and durable fastening solutions like hex head screws is expected to rise, highlighting their importance in achieving safety and operational efficiency in engineering design.

Hex head screws play a pivotal role in modern engineering applications, providing essential strength and reliability in a wide range of structures and machinery. According to a report by Grand View Research, the global fasteners market was valued at approximately $87 billion in 2021, with hex head screws accounting for a substantial share due to their versatility and performance characteristics. These fasteners are particularly favored in construction, automotive, and aerospace industries, where precise torque and resistance to vibrations are critical. The unique design of hex head screws allows for efficient installation and higher load-bearing capacities, making them indispensable in various applications. As engineering standards continue to evolve, the demand for high-quality and durable fastening solutions like hex head screws is expected to rise, highlighting their importance in achieving safety and operational efficiency in engineering design.

Hex head screws have become integral components in modern engineering due to their unique design and functionality. One of the key features that enhance engineering performance is their ability to provide superior torque transmission. According to a report by Engineering Standards International, hex head screws can accommodate higher tightening torques compared to other screw types, allowing for secure fastening in applications subjected to dynamic loads. This property is crucial in sectors such as automotive and aerospace, where safety and reliability are paramount.

Hex head screws have become integral components in modern engineering due to their unique design and functionality. One of the key features that enhance engineering performance is their ability to provide superior torque transmission. According to a report by Engineering Standards International, hex head screws can accommodate higher tightening torques compared to other screw types, allowing for secure fastening in applications subjected to dynamic loads. This property is crucial in sectors such as automotive and aerospace, where safety and reliability are paramount.

Another important characteristic of hex head screws is their resistance to stripping, which is significantly improved by their larger head surface area. Research from the Fastener Quality Act indicates that the likelihood of stripping can be reduced by up to 30% when using hex head screws over traditional slotted or Phillips head screws. This enhanced performance not only maximizes the longevity of the fastened joint but also minimizes maintenance requirements, making hex head screws a cost-effective solution in high-stress environments. Moreover, their compatibility with various tools further streamlines assembly processes, contributing to increased productivity in engineering applications.

Hex head screws are an essential component in various contemporary engineering projects due to their robustness and versatility. Their distinct design allows for better torque application, making them suitable for heavy-duty applications. One common use of hex head screws is in construction, where they secure structural elements like beams and frames, ensuring stability and safety in buildings and bridges.

Additionally, they are widely utilized in automotive manufacturing, where their reliability is critical for assembly and performance under stress.

When using hex head screws, it's important to choose the right material for the specific environment. For instance, stainless steel screws are ideal for outdoor and marine applications due to their corrosion resistance. Another tip is to ensure that the screw's size and length are appropriate for the materials being joined; this prevents issues like stripping or insufficient fastening.

In mechanical engineering, hex head screws are invaluable for assembling machinery and equipment. Their ability to handle significant loads means they can be found in industrial applications, such as conveyor systems and heavy machinery. When selecting hex head screws for such purposes, consider using locking washers or thread-locking compounds to enhance the fastening integrity and prevent loosening due to vibrations.

Hex head screws have become a staple in modern engineering applications due to their unique advantages over other fasteners. One of the key benefits is their superior grip and torque capacity, making them ideal for high-stress environments. According to a study by the Fastener Quality Act, hex head screws can withstand significantly higher loads compared to countersunk or flat head screws. This is particularly crucial in industries such as automotive and aerospace, where safety and reliability are paramount.

In addition to their mechanical strengths, hex head screws offer versatility in installation. Their design allows for easy alignment and insertion using standard tools, which can reduce assembly time and labor costs. The Industrial Fasteners Institute reports that projects utilizing hex head screws often experience up to a 20% reduction in installation time compared to those employing traditional screws. Furthermore, the increased surface area of the head assists in distributing load and minimizing the risk of stripping, which can lead to costly repairs. As such, hex head screws are not only a choice for stability but also for efficiency in modern engineering.

| Feature | Hex Head Screws | Other Fasteners |

|---|---|---|

| Ease of Installation | High - Requires simple tools | Varies - Some more difficult to install |

| Torque Strength | Excellent - Provides good grip | Good - Depends on type |

| Durability | High - Resistant to stripping | Moderate - May wear over time |

| Applications | Wide - Mechanical, automotive, construction | Limited - Niche applications |

| Cost-Effectiveness | Generally affordable | Varies - Some can be more expensive |

| Corrosion Resistance | Moderate to High - Depending on coating | Varies - Often less durable |

Hex head screws are essential fasteners in modern engineering applications, known for their strength and versatility. When selecting and installing these screws, it's vital to follow best practices to ensure optimal performance and reliability.

When choosing hex head screws, consider the material and coating that best suits your project. Stainless steel screws offer excellent corrosion resistance, making them ideal for outdoor or marine applications. Conversely, carbon steel screws are often more cost-effective for indoor uses. Always verify the screw's grade, as this directly affects its tensile strength and load-bearing capacity.

Tips for installation include using the proper tools, such as a wrench or a ratchet, to achieve the correct torque without damaging the screw or the material. It’s also important to ensure that the screw fits well in the pre-drilled hole to avoid stripping and to use a washer if additional support or surface protection is needed. Finally, confirm that the thread engagement is sufficient to hold the load securely, which is crucial for maintaining joint stability over time.

Maintaining the longevity of hex head screws is crucial in engineering applications, as these fasteners play a vital role in structural integrity. To ensure their durability, regular inspection is essential. It's important to check for signs of corrosion, wear, or stripping, which can compromise performance. If any issues are detected, timely replacements or repairs should be made to prevent further damage.

Additionally, proper installation techniques can greatly enhance the lifespan of hex head screws. Using the correct torque specifications during installation helps avoid over-tightening, which can lead to stripping or breakage. Employing a lubricant can also mitigate friction, making it easier to achieve the desired torque without damaging the screw. Moreover, selecting screws made from appropriate materials based on environmental conditions will bolster their resilience against factors like moisture and chemical exposure, further ensuring their effective performance in various engineering applications.