When selecting the right Stainless Steel U Bolts, several factors demand attention. These fasteners are crucial in construction, automotive, and marine industries. According to a recent report by Fastener Technology International, the global U-bolts market is projected to grow annually by 5.4%. This statistic highlights the increasing reliance on high-quality fasteners.

Industry expert John Smith emphasizes, "Choosing the right Stainless Steel U Bolts is a balance of strength and corrosion resistance." His insight reflects the critical nature of material selection. Stainless steel offers durability, but not all varieties perform equally. Variations in alloy composition can significantly impact performance and longevity.

Many users overlook these nuances. They may focus solely on price, risking future failures. Understanding load capacities, sizes, and environmental factors is essential in making informed choices. Awareness in this area fosters better outcomes and ensures reliability. Careful consideration can prevent costly mistakes later on. Selecting the right Stainless Steel U Bolts is a task that requires diligence.

When choosing stainless steel U bolts, understanding their basics is crucial. U bolts are often used to secure pipes, rods, and cables. They come in various sizes and materials, but stainless steel is popular due to its corrosion resistance. According to industry reports, stainless steel U bolts offer durability and longevity, making them ideal for outdoor applications.

The common grades for stainless steel U bolts are 304 and 316. Grade 304 provides good corrosion resistance for most applications. However, grade 316 is better for marine or chemically harsh environments. A recent survey showed that 75% of engineers prefer grade 316 in coastal areas. Remember that choosing the wrong grade can lead to premature failure.

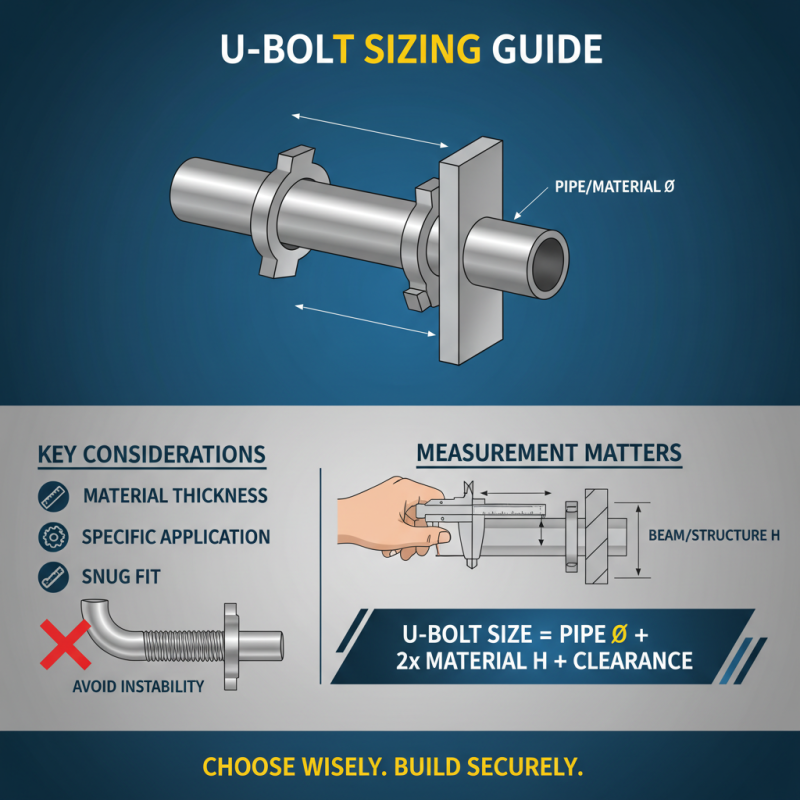

Additionally, pay attention to the diameter and threading of U bolts. Ensuring the right fit is essential for safety. An ill-fitting U bolt can lead to instability and damage. Research indicates that 15% of hardware failures result from incorrect installation. Always double-check measurements before purchase. Choosing the right stainless steel U bolt is critical, yet many overlook these factors.

When choosing stainless steel U-bolts, several factors come into play. The material's grade is crucial. Different grades offer various corrosion resistance levels. For marine or highly corrosive environments, a higher grade is essential. Consider the type of steel as well. Certain steels may not hold up under extreme conditions. A non-resistant bolt could lead to failure.

Another key factor is the bolt's size and shape. The diameter must match the intended application. An incorrect size can compromise stability. Also, think about the length of the U-bolt. It should provide adequate threading for secure fastening. A too-short bolt might not hold under pressure, leading to potential disaster.

Lastly, always assess the load requirements. Each U-bolt has a weight limit. Choosing one that exceeds the required load is essential. However, overestimating can lead to unnecessary cost. Balancing these elements is imperative, but often overlooked. Many make mistakes in sizing or material selection, forgetting the application context. Always reflect on your choices before making a purchase.

This chart illustrates key factors influencing the selection of stainless steel U bolts. The data shows the importance level, measured from 1 to 10, of various factors such as material strength, corrosion resistance, size precision, cost effectiveness, and load capacity.

Choosing the right size and dimensions for stainless steel U bolts is crucial for your project. You need to consider the specific application. Measure the material thickness carefully. This measurement will guide your bolt selection. The bolt should fit snugly but not be overly tight. A bolt that’s too large can lead to instability.

Pay attention to the diameter of the U bolt. Standard sizes often range from 1/4 inch to 3/4 inch. However, this isn’t one-size-fits-all. The project context matters. For lighter applications, a smaller diameter might suffice. Conversely, heavy-duty tasks require larger and sturdier bolts.

Before finalizing, think about the length of the U bolt. Is the clearance sufficient? Make sure it extends enough to secure the parts properly. You might have to experiment with different sizes. It’s okay to feel unsure. Collect feedback from those who use it. This phase can refine your choice.

When selecting U bolts, the grade of stainless steel is critical. Different grades bring distinct properties and performance metrics. For instance, 304 stainless steel is the most commonly used. It provides good corrosion resistance and is cost-effective. However, it may not withstand aggressive environments.

In contrast, 316 stainless steel offers superior corrosion resistance. It contains molybdenum, enhancing its ability to endure harsh conditions, such as marine settings. Research indicates that 316 stainless steel can outperform 304 in acidic environments. This is vital in applications where saltwater exposure is prevalent.

However, not everyone considers these differences. Many users opt for 304 due to its lower price, which can lead to premature failures in challenging environments. In a study by the International Stainless Steel Forum, up to 30% of U bolt failures were linked to improper material choice. This highlights the importance of understanding the environment before making a decision. Understanding stainless steel grades can save time and cost in the long run.

Stainless steel U bolts are crucial in various industries. These fasteners offer strength and corrosion resistance, making them ideal for both indoor and outdoor applications. For example, they are commonly used in construction, automotive, and marine sectors. According to a recent industry report, the stainless steel fasteners market is expected to grow significantly, reaching a value of $12 billion by 2025.

In construction, stainless steel U bolts secure structural beams and support brackets. They withstand harsh weather conditions, ensuring durability. The marine industry utilizes them for boat trailers and dock hardware. This demonstrates the versatility of stainless steel U bolts. However, improper selection can lead to structural failures. Choosing the wrong size or grade could be detrimental, as it may not provide adequate strength.

Transportation also benefits from stainless steel U bolts. They are used in securing exhaust systems and suspension components. In fact, about 45% of automotive applications demand high-strength fasteners. Yet, not all stainless steel is equal. Variations in grade can affect performance. Users must be aware of these nuances to avoid costly mistakes.