When embarking on a project that involves the use of Neoprene Washers, understanding their significance is crucial. Dr. Emily Carter, an industry expert in sealing solutions, emphasizes, "Choosing the right Neoprene Washer can make or break your project." This statement underscores the importance of careful selection in achieving desired results.

Neoprene Washers are known for their durability and flexibility, making them ideal for various applications. They resist water, oil, and chemicals, which adds to their versatility. However, many overlook the nuances of selecting the right type. For instance, thickness, diameter, and hardness must align with project requirements. An improperly chosen washer might lead to leaks or structural failures.

In a world where precision is key, the challenge remains to select the most suitable Neoprene Washers. With numerous options available, it can be easy to feel overwhelmed. Reflecting on this, one should consider not just the price, but the long-term performance of these washers. Each project has unique needs, and awareness of these factors can lead to more successful outcomes.

When choosing neoprene washers for your projects, certain key properties should guide your selection. Neoprene is known for its excellent resistance to temperature fluctuations and various chemicals. This makes it suitable for both indoor and outdoor applications. Reports indicate that neoprene maintains its elasticity over a wide range of temperatures, typically from -40°C to 100°C. This ability is vital for projects requiring durable performance in diverse conditions.

Another important property is the compression set of neoprene washers. A study by the Rubber Manufacturers Association found that neoprene can withstand significant compressive loads without losing its original shape. This characteristic ensures the washer maintains a good seal over time, preventing leaks or failures. Additionally, neoprene offers a decent resistance to oils and fuels, making it ideal for automotive and industrial applications. Yet, not all neoprene washers are created equal. The formulation and thickness can greatly influence their effectiveness and lifespan.

While neoprene washers provide numerous advantages, it is crucial to acknowledge the trade-offs. Certain environments may lead to degradation over time, particularly when exposed to ozone or ultraviolet light. Understanding these limitations can ensure that you make informed choices, particularly when conditions are not optimal. Thus, when selecting neoprene washers, consideration of their properties is essential for achieving the best results in your projects.

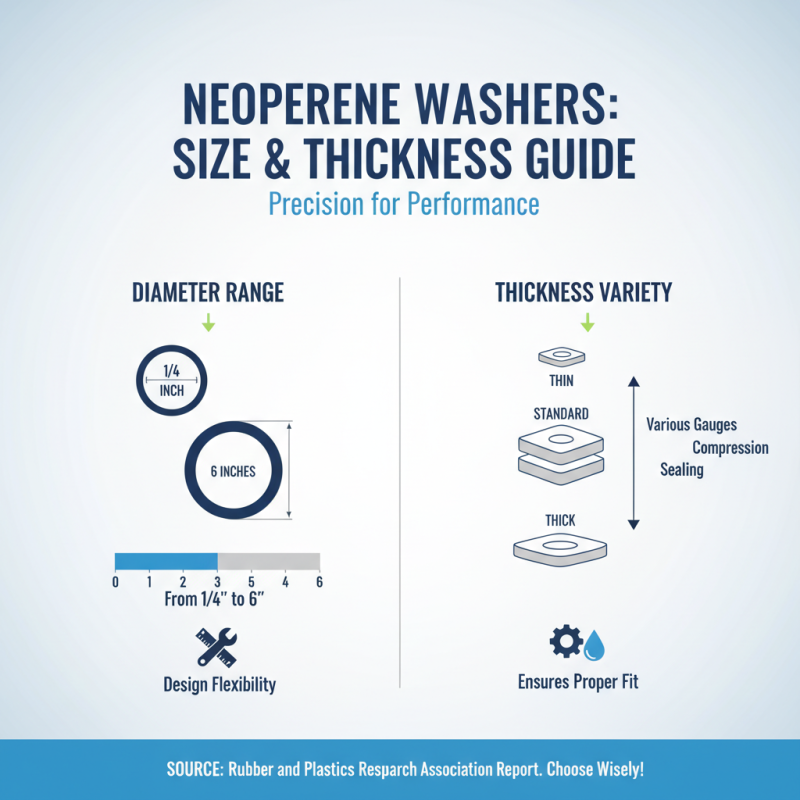

When selecting neoprene washers, size and thickness matter significantly. Neoprene washers come in various dimensions, catering to different applications. A report by the Rubber and Plastics Research Association states that washers can range from 1/4 inch to 6 inches in diameter. This variety allows for flexibility in design and ensures a proper fit.

Thickness is another crucial aspect. Neoprene washers are available in thicknesses from 1/16 inch to 1/2 inch. Thicker washers provide better sealing capabilities, but they might not fit all applications. For instance, in hydraulic systems, a thicker washer may be necessary to handle higher pressure. However, improperly sized washers can lead to leakage.

Choosing the right size and thickness requires careful consideration. Many projects fail due to incorrect dimensions. The ideal fit should prevent issues like wear or compression failure. It’s important to evaluate the specific requirements of your project. Always consider these factors thoroughly to avoid costly mistakes down the line.

Neoprene washers are versatile components used in multiple applications. They offer excellent resistance to weather, oils, and chemicals. This makes them ideal for both indoor and outdoor projects. A study by the Adhesives and Sealants Industry Association highlighted that neoprene materials resist degradation better than many alternatives. This increases their reliability in demanding environments.

In plumbing, neoprene washers play a crucial role. They provide effective seals that prevent leaks. According to a report from the Institute of Plumbing, using neoprene washers reduces water loss by up to 30%. This is significant for sustainability efforts. Yet, their effectiveness can sometimes diminish under extreme temperatures. That’s a point worth considering during installation.

In construction, these washers are essential for securing hardware. They cushion components, preventing wear and tear. However, not all projects require neoprene. In some cases, users may overlook the importance of material choice. Choosing the wrong washer can lead to project failures. Understanding your specific needs is key to making the right decision.

The following chart illustrates the common applications and uses of neoprene washers in various projects, highlighting their effectiveness across different scenarios.

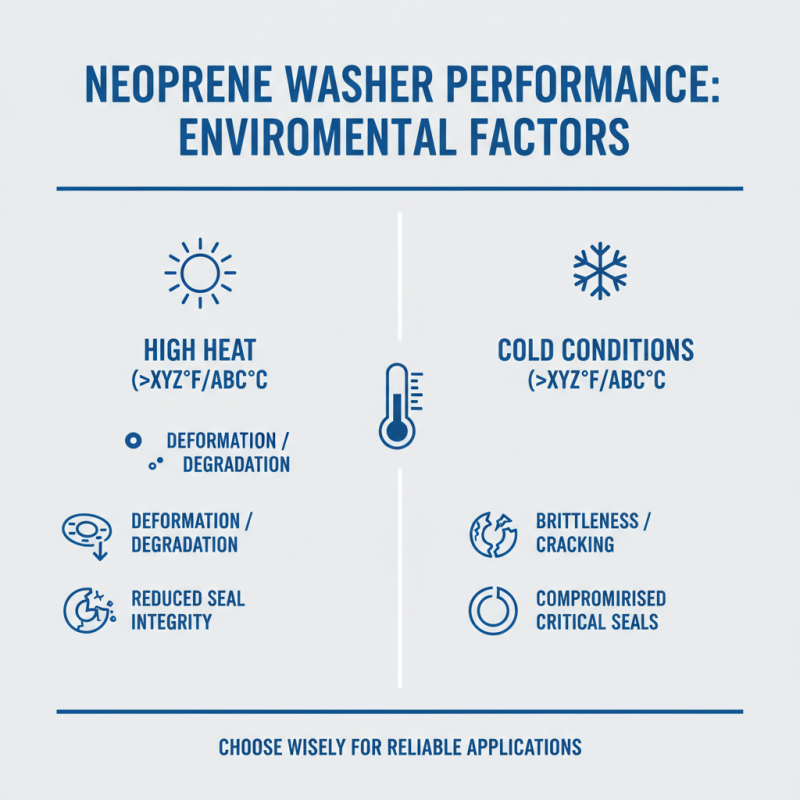

When choosing neoprene washers, it’s essential to consider environmental factors. Temperature can greatly influence performance. High heat can lead to deformation or degradation. Cold conditions might cause brittleness. This can impact the seal integrity, especially in critical applications.

Exposure to chemicals is another concern. Some chemicals can break down neoprene. For instance, oils and solvents can weaken the material. It’s wise to evaluate the environment where washers will be used. Proper testing in real-life conditions can reveal weaknesses.

Humidity levels shouldn’t be overlooked either. High moisture can create issues like mold or mildew. In these cases, the lifespan of neoprene washers may shorten. Users might find themselves frequently replacing washers, leading to increased costs. It’s important to conduct regular assessments of washer performance. Reflecting on these factors can lead to better choices in the long run.

When sourcing neoprene washers, cost is a crucial factor. The average market price for neoprene washers can range between $0.10 and $1.00 each, depending on size and thickness. According to a recent industry report from Research and Markets, the global neoprene market is expected to grow significantly, leading to fluctuating prices. Understanding these dynamics is essential when planning budgets.

Additionally, consider sourcing options. Buying locally may be more convenient, but it often comes at a premium. Online suppliers might offer lower prices, but shipping costs can add up. A study by IBISWorld notes that companies involved in neoprene manufacturing have experienced a 3.5% annual growth rate. This suggests an increasing number of suppliers, which could lead to greater competition and better prices for end users.

It's important to evaluate the quality versus the cost. Cheaper neoprene washers might lack durability and performance. If they fail, the cost of replacements can quickly surpass any savings made initially. Reflecting on long-term value is key. Consider all these factors to make informed decisions that could impact your projects significantly.