Coach Screws play a vital role in the world of DIY projects. These screws are designed for strength and versatility. According to Mark Thompson, a leading hardware expert, "Coach Screws provide the durability needed for secure connections in any project." His insight highlights their importance.

In practical terms, Coach Screws are used in various applications. They work exceptionally well for connecting timber and support structures. Their coarse threads grip materials tightly, ensuring a solid bond. This feature makes them popular among DIY enthusiasts and professionals alike.

However, not all Coach Screws are created equal. Choosing the right length and gauge can be challenging. Many struggle with compatibility. It's essential to consider the materials you are working with. Understanding this can greatly impact the outcome of your project. Reflecting on your choices can lead to better results next time.

Coach screws are pivotal in various DIY projects. These screws boast a unique design, incorporating a thick, partially threaded shaft. This feature allows them to be driven deeply into wood, creating a strong grip. Their broad heads also provide a reliable surface for tools. According to a report by the American Wood Council, a properly installed coach screw can support loads exceeding 1,500 pounds in certain applications. This strength is particularly beneficial when working with heavy timber or board applications.

Understanding the functionality of coach screws is essential. They excel in situations where traditional screws may fail. For instance, their resistance to stripping is notable. Professionals suggest using these screws in furniture assembly or decking projects. However, not all applications may warrant their use, as their size can become an issue in tight spaces. Additionally, some inexperienced DIYers might exceed torque limits, leading to breakage. Be mindful of how torque can impact the integrity of your project.

Overall, coach screws are foundational in ensuring the durability and stability of various constructions. A well-chosen coach screw can bring peace of mind to DIY enthusiasts. Just remember, there's always room to learn and improve your technique as you tackle new projects.

When it comes to DIY projects, coach screws are often overlooked. These screws have unique features that make them truly beneficial. Their large, coarse threads provide excellent grip in wood, making them ideal for heavy-duty applications. The head design allows for easy driving, even in tough materials. Using them can significantly improve the stability of your structures.

One key benefit is the ability to resist shear forces. This makes coach screws perfect for furniture construction or outdoor projects. They can withstand weight without stripping. However, improper installation can lead to issues. Over-tightening might crack the wood, while under-tightening can result in loose connections. It’s important to find that balance for the best results.

Additionally, coach screws are available in various lengths and materials. This versatility allows for application in different environments. For example, galvanized options resist rust, making them suitable for outdoor use. Yet, the abundance of choices might lead to confusion for DIYers. Sometimes, it takes trial and error to find the perfect fit for your project. Finding the right screw is crucial, but experimenting can also lead to unexpected solutions.

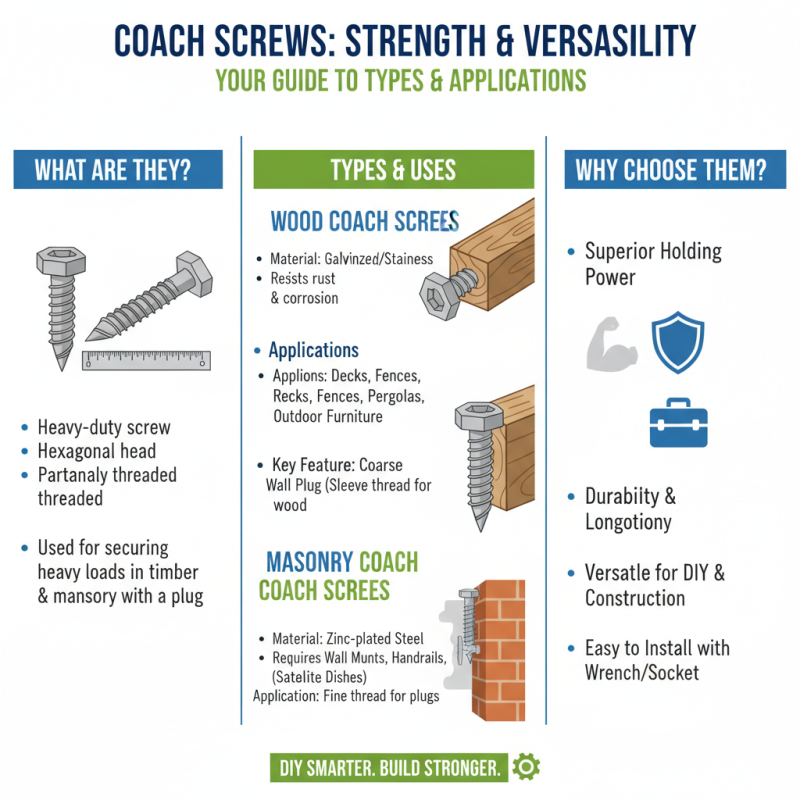

Coach screws are crucial for various DIY projects, offering strength and versatility. Understanding the different types of coach screws and their applications is vital for selecting the right one. Wood coach screws are common in outdoor projects, providing excellent resistance to rust and corrosion. These screws are designed for heavy loads, making them suitable for structures like decks and fences.

Metal coach screws, on the other hand, are perfect for steel or masonry applications. They feature a hexagonal head for easy tightening. According to industry reports, using the correct type of screw can improve structural integrity by up to 30%. This data highlights the importance of making informed choices in DIY projects.

Tips: Always pre-drill to ensure a secure fit. This prevents wood from splitting, which can happen with larger screws. Make sure to match the screw length to your project needs. For enhanced durability, consider using screws with a coating that resists weather elements. Remember, not all screws are created equal. Reflect on what you need before making a purchase.

Installing coach screws properly is crucial for achieving sturdy and reliable connections in DIY projects. These screws are designed to hold heavy loads and withstand various stresses. According to a recent industry report, using the correct installation technique can improve load-bearing capacity by up to 30%.

Begin by selecting the right size of coach screw for your project. A screw that’s too short may not provide sufficient hold. Undersized screws can snap under pressure. Pre-drilling holes is essential. This helps to avoid splitting the wood and maintains structural integrity.

When inserting coach screws, apply steady pressure. Avoid overtightening; this can strip the socket. The recommended torque for most applications is typically around 30 Nm. It's vital to continuously check the alignment. Misalignment leads to weak joints. Keep tools clean and free from debris throughout the process. Remember, a clean workspace contributes to better outcomes. Each step matters, and attention to detail pays off. Mistakes can happen, but they offer valuable lessons as you refine your technique.

Coach screws are vital for many DIY projects. However, their performance can be affected by several factors. Proper maintenance can extend their lifespan. Regular inspection is essential. Check for signs of rust or wear. Replace any damaged screws immediately.

When working with coach screws, using the correct installation technique is crucial. Pre-drilling is often necessary. It prevents wood from splitting. Also, using a washer can help distribute the load evenly. Clean the screws periodically to remove debris and dirt.

Storing coach screws in a dry place is important. Moisture can lead to corrosion. Consider organizing them in labeled containers. This can save time when working on projects. Reflecting on your practices can lead to improvement. A little care goes a long way.

This chart illustrates the importance of various types of coach screws for DIY projects, showcasing their recommended usage percentages. Wooden coach screws are the most common, particularly popular for woodwork, while other types serve specific applications effectively.