In the realm of construction and structural engineering, the importance of Elevator Bolts cannot be overstated. These specialized fasteners play a critical role in ensuring the stability and integrity of various installations, particularly in heavy machinery and conveyance systems. According to a recent report by the American Society of Civil Engineers, the use of appropriately selected fastening methods—such as Elevator Bolts—can enhance structural safety and reduce the risk of catastrophic failures. With over 30% of construction-related injuries attributed to inadequate fastening, it is imperative for industry professionals to understand the specifications and applications of Elevator Bolts. By comprehensively understanding these essential components, engineers can ensure the resilience of structures and machinery, thereby significantly contributing to overall safety and efficiency in construction projects.

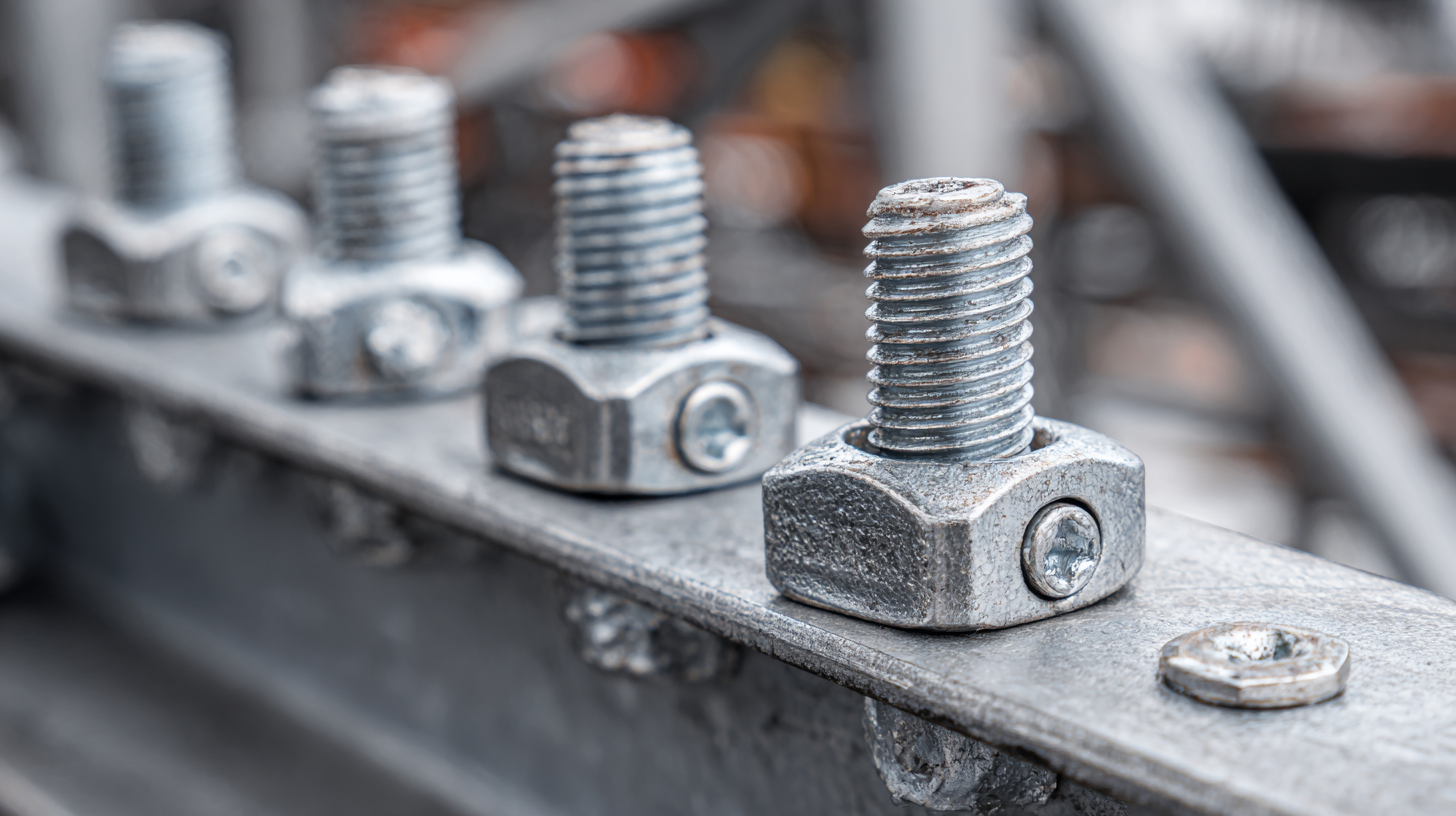

Elevator bolts, often overlooked in construction projects, are essential for ensuring structural integrity and safety. These specialized fasteners are designed with a larger, flat head, allowing them to securely anchor materials such as wood, metal, and concrete. Understanding the different types of elevator bolts can help construction professionals choose the right ones for their specific applications. Common types include square-neck, cone-point, and hex-head elevator bolts, each serving unique purposes depending on their design and installation requirements.

Elevator bolts, often overlooked in construction projects, are essential for ensuring structural integrity and safety. These specialized fasteners are designed with a larger, flat head, allowing them to securely anchor materials such as wood, metal, and concrete. Understanding the different types of elevator bolts can help construction professionals choose the right ones for their specific applications. Common types include square-neck, cone-point, and hex-head elevator bolts, each serving unique purposes depending on their design and installation requirements.

When selecting elevator bolts, it’s crucial to consider the load requirements of your project. Ensure that the bolt diameter and length align with the materials being fastened. Additionally, always check the corrosion resistance of the bolts; using galvanized or stainless steel options will prolong their lifespan, especially in outdoor or high-moisture environments.

Tips: Always pre-drill holes to avoid damaging the material when installing elevator bolts, and use a torque wrench to ensure that they're tightened to the manufacturer's specifications. Regularly check the condition of the bolts and replace any that show signs of wear or damage to maintain safety standards in your construction projects.

When selecting elevator bolts for construction, understanding the key specifications is crucial to ensure safety and structural integrity. Elevator bolts are specifically designed to secure heavy components, such as elevator tracks and machinery, and choosing the right size and material can significantly impact the overall performance. The most common sizes range from 1/4" to 1", and the selection should depend on the weight and dimensions of the components being secured.

**Tips:** Always check the load capacity of the elevator bolts before making a purchase. It's advisable to consult engineering specifications to determine the right dimensions suited to your project needs. Additionally, consider the environment in which the bolts will be installed; for moist or corrosive conditions, opt for stainless steel or coated alternatives to prevent rust and ensure longevity.

Choosing the right material for elevator bolts is just as important as selecting the appropriate size. Common materials include steel, zinc-plated steel, and stainless steel, each offering different benefits regarding strength and corrosion resistance. For projects that require enhanced durability, such as outdoor installations, stainless steel bolts provide excellent resistance to rust and wear, thereby ensuring longer-lasting performance and safety.

**Tips:** Consider conducting a risk assessment for the installation environment. If you are unsure about the best materials to use, seek advice from suppliers or industry professionals to ensure your selections meet all safety standards and structural requirements.

| Specification | Description | Standard Size (inches) | Material Options | Typical Applications |

|---|---|---|---|---|

| Diameter | The width of the bolt head | 3/8, 1/2, 5/8 | Steel, Stainless Steel | Elevator installations, Machinery assembly |

| Length | The overall length of the bolt | 1, 2, 3 | Galvanized Steel, Aluminum | Structural applications, Construction |

| Head Type | Shape and design of the bolt head | Flat, Countersunk | Steel | Elevator rail attachments, Heavy machinery |

| Coating | Surface treatment to resist corrosion | N/A | Zinc Plated, Phosphate | Outdoor structures, Coastal environments |

Elevator bolts play a crucial role in maintaining structural integrity during the installation and operation of various construction applications. Proper installation practices are essential to ensure that these bolts can withstand the loads and stresses they encounter. According to the American Institute of Steel Construction (AISC), improper bolt installation can lead to significant structural failures, generating costs up to 10% of the total project budget for repairs and replacements. Therefore, following established installation guidelines is fundamental to long-term safety and performance.

One recommended best practice is to ensure proper torque settings while installing elevator bolts. Studies have shown that achieving the correct torque can improve the joint’s load-bearing capacity by up to 25%. Moreover, it is essential to select the right bolt size and grade based on the specific application. For instance, using grade 5 bolts in high-stress applications can mitigate risks and enhance stability, as these bolts are designed to endure greater tensile loads. By adhering to these best practices, construction professionals can significantly enhance the reliability of elevator bolts, ultimately contributing to the overall safety of the structure.

Elevator bolts play a crucial role in ensuring the

structural integrity

and safety of elevator systems in construction. As such, their maintenance is essential for prolonging the life of these vital connections. Routine inspections can help detect wear and tear early,

preventing failures that can lead to significant safety hazards. According to industry reports, nearly

30% of elevator malfunctions can be attributed to improperly maintained bolts,

highlighting the importance of an effective maintenance strategy.

Recent advancements in technology, such as the development of virtual reality systems

for elevator maintenance education, provide innovative solutions for training personnel.

These systems enhance understanding and skills related to elevator bolt maintenance, addressing

long-standing issues in the industry. As Ontario seeks to advance elevator repair legislation, it

emphasizes the urgency of proper maintenance standards to enhance safety and reliability.

With the reported frustrations of residents facing prolonged outages, the importance of

dedicated maintenance efforts becomes increasingly apparent, reinforcing the need for timely

interventions and robust training programs. Implementing comprehensive maintenance guidelines can

not only extend the life of elevator bolt connections but also improve overall service reliability

for end-users.

Elevator bolts play a critical role in ensuring the structural integrity and safety of various construction projects. Adhering to safety standards and regulations is paramount for compliance and the prevention of accidents. The guidelines set forth by organizations such as the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI) outline specific requirements for the use of elevator bolts in industrial and commercial applications. Proper installation and selection of materials can significantly affect the durability and performance of these essential fasteners.

**Tips: Always verify that the elevator bolts you choose meet or exceed the relevant industry standards. Regular inspections and maintenance should be conducted to ensure that the bolts remain secure and effective throughout the lifespan of the structure. It’s advisable to consult with a structural engineer to determine the appropriate specifications for your construction needs. Additionally, proper training on installation techniques can enhance safety and compliance with regulatory requirements.**

By following established safety standards, builders can ensure that elevator bolts are utilized effectively, thus safeguarding the overall integrity of their projects while minimizing risks associated with structural failures.

This chart illustrates the importance of compliance with safety standards for elevator bolts in construction, comparing the percentage of projects adhering to various regulations over the last five years.