When choosing the right fasteners for your projects, Hex Head Screws often shine as a top choice. According to John Smith, a renowned expert in the fastening industry, "Hex Head Screws offer unmatched versatility and strength." Their unique six-sided shape provides excellent grip, making them a reliable option for various applications.

Hex Head Screws come in different materials, coatings, and sizes. This variety meets the specific needs of different projects. For instance, stainless steel hex screws resist corrosion and wear. Others, like zinc-plated options, offer additional protection. Yet, selecting the right type can be overwhelming. Not all screws work effectively with every material.

It's essential to consider the project environment and load requirements. Many users make mistakes by underestimating the importance of these factors. A hesitant decision can lead to issues such as structural failure. Therefore, understanding the best hex head screw types for your projects is crucial for success.

Hex head screws are crucial for a variety of projects. Their distinct shape allows for better torque application. This design enhances grip and minimizes slippage, making them ideal for heavy-duty tasks. According to a report by the Fastener Technology Institute, over 30% of construction projects favor hex head screws for structural assemblies. Their reliability is a significant reason for this trend.

In automotive and machinery applications, hex head screws are indispensable. They provide strong fastening and are resistant to vibration. Data indicates that 45% of professionals in the engineering sector opt for hex head varieties for these reasons. However, there are challenges. Not all materials respond well to hex head screws, potentially leading to stripping or breakage. Proper installation techniques are critical to avoid failures.

Different projects require varied specifications for hex head screws. Variations in size and material can affect performance. Stainless steel, for example, offers corrosion resistance but may be more expensive. This can lead to budgetary constraints for some projects. Evaluating material choices carefully is necessary to strike a balance between cost and functionality.

When it comes to hex head screws, understanding the various types available is crucial for any project. Hex head screws are known for their versatility and strength, making them popular in construction and mechanical applications. The major classifications include standard hex head screws, flanged hex head screws, and socket hex head screws. Each type serves specific needs. For instance, flanged hex screws distribute load over a larger area, which enhances grip.

Data from recent industry reports suggest that the hex screw market is projected to grow by 5% annually. This growth highlights their importance in manufacturing sectors. However, choosing the right type isn't always straightforward. Poor application can lead to failures, which results in costly downtime.

Tips: Always match the screw type with your material. For wood, try using standard hex screws. For metal or heavy-duty applications, opt for socket hex screws. Remember, not all projects require high-strength options. Sometimes, over-engineering can be wasteful and unnecessary. Evaluate your project's needs carefully and avoid common mistakes.

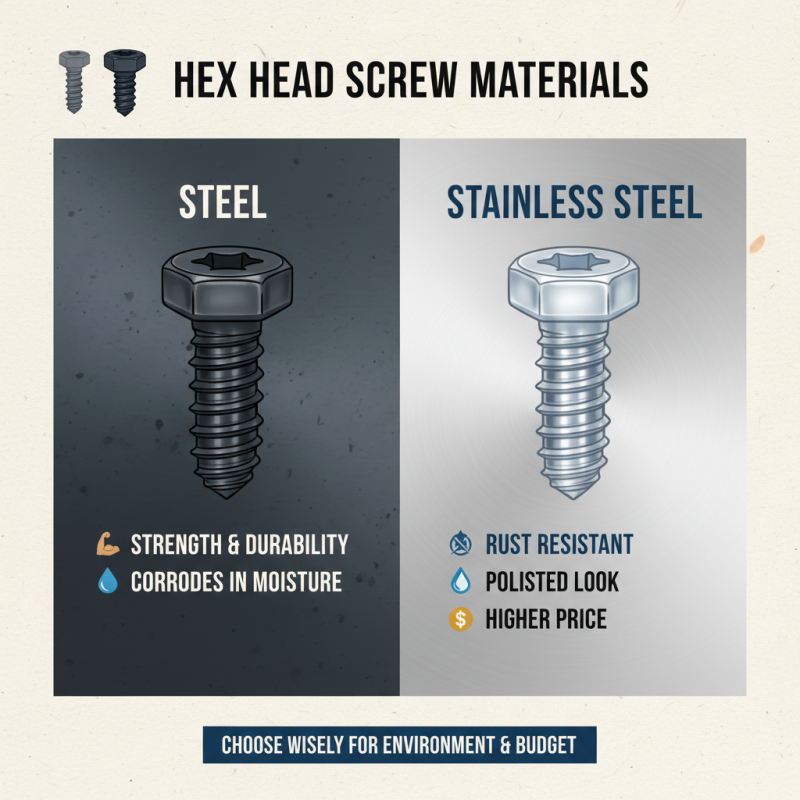

When selecting hex head screws, material choice is critical. Steel, for example, offers strength and durability. However, it can corrode in moist environments. Stainless steel is a reliable alternative. It resists rust and looks polished but comes at a higher price.

Another option is brass. It’s lightweight and aesthetically pleasing. But brass screws may not provide the same structural strength as steel. Aluminum screws are another lightweight choice. They are resistant to corrosion but can strip easily under heavy torque.

Each material has its drawbacks and advantages. A project’s specific needs often dictate the best choice. Assess the environment and load requirements carefully. Some factors might not seem obvious at first. Take your time to reflect on the trade-offs before making a decision.

When selecting the right hex head screw for your project, consider various factors. The material of the screw is crucial. Stainless steel offers corrosion resistance, ideal for outdoor use. Carbon steel is strong but may rust without a coating. Choose based on your environment.

Depth and size are significant too. A screw that’s too short won’t secure materials effectively. If it’s too long, it could cause damage. Always match the screw length to the thickness of the materials you are using.

Tip: Double-check the specifications. Sometimes, it’s easy to misjudge the required length and thread count.

Don't ignore the screw's drive type. Options like Phillips, hex, or square drive each have unique benefits. Some provide better torque, while others offer a simpler installation. Testing a few types can help determine what fits best for your needs.

Tip: Try different drive types on scrap material to see which works best.

In the end, assess your project requirements carefully. A slight oversight in choosing screws can lead to structural issues. Regularly review your options and gather feedback from others to improve your choices.

Hex head screws are a popular choice for many projects due to their ease of use and reliability. When installing these screws, it’s important to consider the surface material. Certain materials require specific approaches. For instance, wood and metal behave differently under pressure. Pre-drilling is often essential for wood to prevent splitting. Metal surfaces may need a pilot hole for better grip and alignment.

Using the right tool is vital. A power drill or impact driver can speed up the process. However, be careful with the settings. Too much torque can strip the head. Tightening should be firm but cautious. Over-tightening is a common mistake, leading to damage and requiring replacements. For harder materials, a hex driver with a longer reach may offer better leverage.

Another factor to think about is the screw's length and diameter. Choosing the wrong size can impact stability. A screw that’s too long may poke through the other side. On the other hand, one that’s too short may not secure properly. Always double-check your measurements before proceeding. It’s easy to overlook details like these, yet they can significantly affect project outcomes.

| Screw Type | Material | Coating | Size Range | Best Use Cases |

|---|---|---|---|---|

| Hex Cap Screw | Steel | Zinc Plated | #10 to 1 | Heavy-duty fastening in metal and wood |

| Hex Head Self-Drilling Screw | Stainless Steel | Black Oxide | #8 to 5/16" | Metal roofing and siding applications |

| Hex Washer Head Screw | Alloy Steel | Galvanized | #10 to 3/8" | Use in outdoor projects for durability |

| Hex Flange Head Screw | Carbon Steel | Plain | #12 to 1/2" | Automotive and manufacturing sectors |

| Hex Head Machine Screw | Brass | Nickel Plated | #6 to 3/8" | Electronic devices and fixtures |