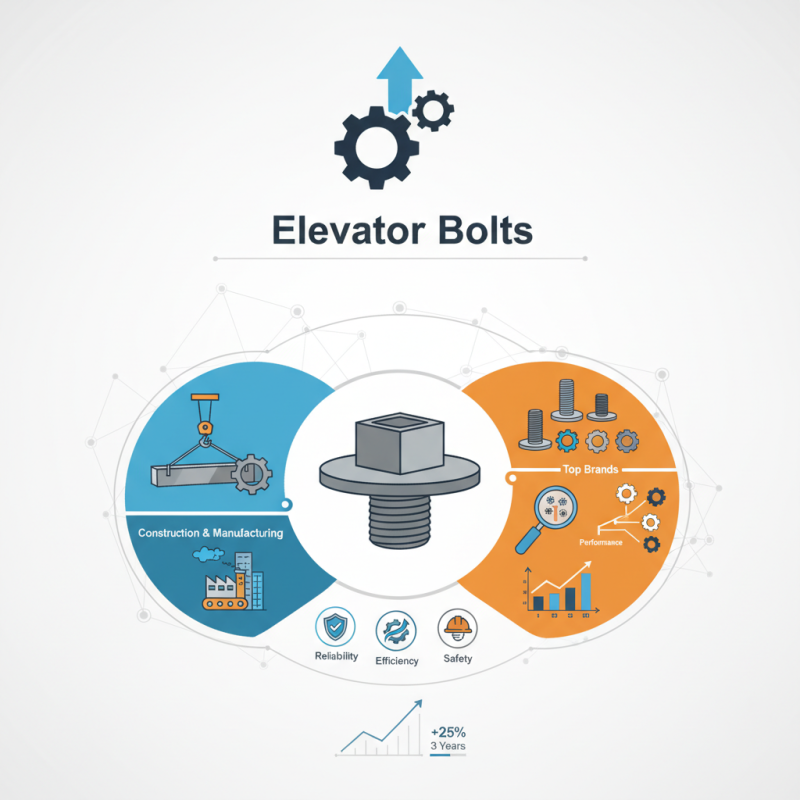

In the fast-evolving construction and manufacturing sectors, the significance of Elevator Bolts cannot be overstated. According to the latest industry reports, the demand for these specialized fasteners has surged by 25% over the past three years. This trend reflects the increasing need for reliable and effective fastening solutions across various applications, from lifting equipment to structural assemblies.

Expert James Whitaker, a renowned figure in the fastener industry, emphasizes the importance of quality in Elevator Bolts: "A well-made elevator bolt is the backbone of safe operation in any lifting mechanism." His insights shed light on the critical role these components play in maintaining safety and efficiency. Understanding their unique features and the brands that excel in this niche market is essential for professionals seeking the best options available.

As the variety of available Elevator Bolts expands, it invites scrutiny regarding performance and suitability. The market is filled with both high-performing brands and lesser-known options, which can lead to confusion. Assessing the right features for specific applications will ultimately determine the effectiveness of these vital components. This exploration into the best Elevator Bolts will help uncover key players and qualities to consider.

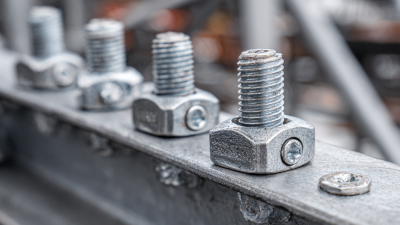

Elevator bolts are crucial in various industries. These fasteners are designed for strength and durability. They feature a large, flat head that distributes the load evenly. This design helps prevent damage to the material being fastened. The bolts come with a square neck under the head, ensuring they stay in place during installation.

When selecting elevator bolts, consider specific attributes. The material is vital: stainless steel and carbon steel are popular options. They offer resistance to wear and corrosion. The diameter and length also matter. These measurements will influence the bolt's strength and suitability for different applications.

Some users may overlook the importance of proper installation. Misalignment can lead to failure. Regular inspections are essential to ensure reliability. It’s a task that can sometimes be forgotten amid other duties. Adequate training for personnel also plays a key role in optimal performance. When used correctly, elevator bolts are dependable components.

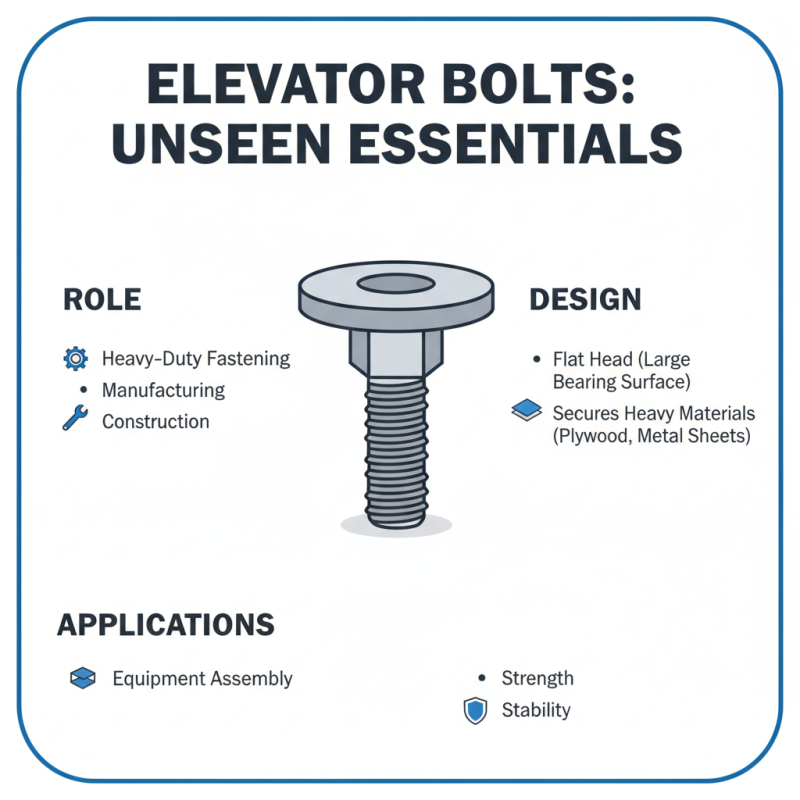

Elevator bolts serve a crucial role in various industries, often unnoticed yet indispensable. These robust fasteners are designed for heavy-duty applications, primarily in manufacturing and construction. Their unique flat heads provide a large bearing surface, making them ideal for securing heavy materials like plywood or metal sheets. In addition, they are frequently used in equipment assembly, where strength and stability are paramount.

In the food industry, elevator bolts facilitate the installation of conveyor belts and equipment. They ensure that heavy components remain securely in place during operations. This enhances safety and efficiency in processing lines. However, the choice of material is vital. Using the wrong material can lead to corrosion and failure, causing downtime and repairs. Moreover, the proper torque is necessary while installing elevator bolts. Over-tightening can damage the components, while loose bolts may compromise safety.

In construction, elevator bolts connect structural elements and equipment. They must withstand extreme forces, especially in high-rise buildings. Yet, some workers overlook maintenance. Ignoring regular inspections can lead to hazards. Regular checks and proper installations are essential for ensuring long-term performance. Understanding these applications is crucial for all industries relying on elevator bolts for stability and strength.

When selecting elevator bolts, various brands offer unique features. A good bolt should provide strength and reliability. Look for options made from durable materials. This ensures longevity and resilience under pressure. Some bolts are designed for specific environments, like damp or corrosive areas. Choosing the correct type can prevent future issues.

Researching different brands is essential. Some focus on heavy-duty applications, while others prioritize ease of installation. Check user reviews to understand real-world performance. A brand’s reputation matters, but personal experience can differ. Quality control can vary between manufacturers, even within the same brand.

Consider consulting with professionals. They can guide you to the best choices based on your needs. Make sure to review specifications closely. Sometimes, the right choice is not the most popular one. Assess how each option aligns with your project requirements. Small details can make a significant difference in performance.

When selecting elevator bolts for installations, several factors come into play. Material quality is paramount. Steel is a common choice as it offers durability and strength. However, it can rust if not coated properly. Consider corrosion-resistant options for high-moisture areas.

Thread design also matters. Some bolts have finer threads, while others have coarse ones. Coarser threads may offer better grip, but elongation can be an issue. Evaluate the type of load and stress the bolts will encounter. The wrong choice can compromise safety.

Lastly, size and length are critical. Too short can lead to loose fittings, while too long may not secure properly. It’s essential to measure accurately before purchasing. Remember, choosing the right elevator bolts affects not just installation but also the overall safety and functionality of the elevator system. Don't overlook these details—they can make a significant difference.

Elevator bolts are essential components in various lifting systems. Proper maintenance is crucial for their longevity and performance. Regular checks can prevent unexpected failures.

Inspect the bolts often. Look for signs of wear or corrosion. Tighten bolts that seem loose. Regular greasing can also extend their life. A little grease can go a long way.

Remember to clean the bolts and surrounding areas. Dirt and debris can trap moisture and lead to rust. Use a soft brush to remove grime without damaging surfaces.

Be mindful of operating conditions. Extreme temperatures can affect the integrity of the bolts. Vibration can also lead to loosening over time. Keep these factors in mind to ensure the bolts perform well.