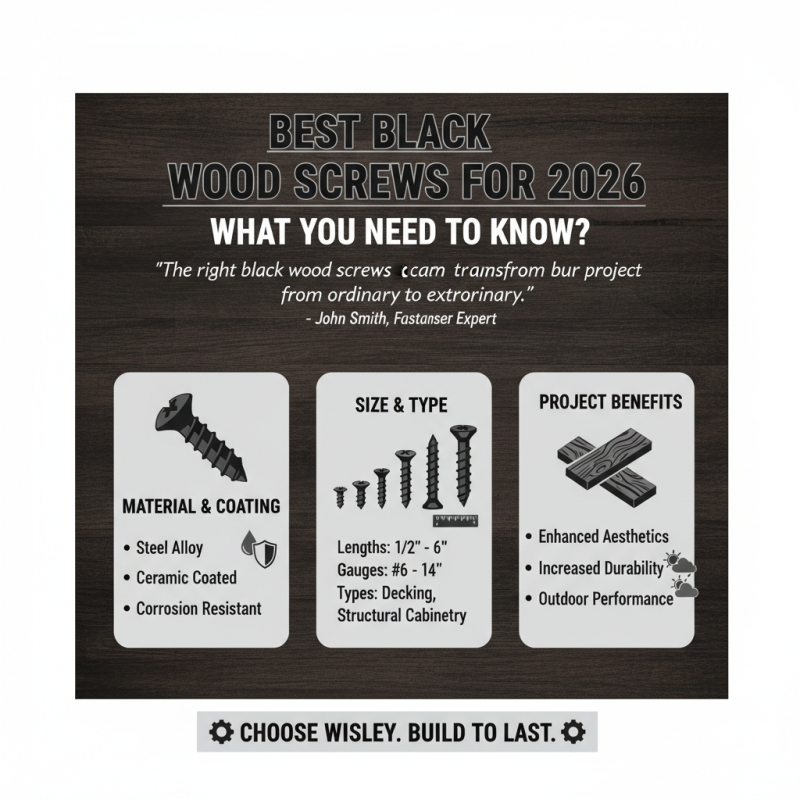

In the world of woodworking, the choice of screws can greatly impact the quality and durability of projects. Black wood screws have gained popularity among professionals and DIY enthusiasts alike. John Smith, a leading expert in the fastener industry, once stated, "The right black wood screws can transform your project from ordinary to extraordinary." This highlights the importance of choosing the right screws for your specific needs.

When selecting black wood screws for 2026, it’s essential to consider various factors. These include the material, coating, and size. Black wood screws not only offer aesthetic appeal but also enhance the longevity of the joinery. A specific coating can prevent rust and increase performance in outdoor projects. However, it’s crucial to acknowledge that not all black wood screws are created equal.

Some may find it challenging to choose the right type or size. Reflection on prior projects can reveal mistakes made with screw choices. The perfect black wood screw might still elude some craftsmen. With thoughtful consideration and expert advice, finding the ideal black wood screws will lead to projects that stand the test of time.

Black wood screws come in various types, each designed for specific tasks. There are coarse-thread screws, ideal for softer woods. They grip well and prevent splitting. Fine-thread screws work best for dense materials. They provide a tight hold, which is crucial for heavy-duty projects.

When selecting black wood screws, consider their coating. A black oxide finish resists corrosion and adds aesthetic appeal. Some screws are treated for additional strength, making them suitable for outdoor use. Pay attention to the length and gauge as well. The wrong size can lead to weak connections.

Not all black wood screws perform equally in different applications. Some might struggle with certain wood types, leading to stripped heads or breakage. It's essential to test screws in your specific material. Reflect on your choices and adjust accordingly. Understanding the subtleties of black wood screws can elevate your project’s quality significantly.

When it comes to black wood screws, the materials used are crucial for durability. A strong screw typically features a core made from high-carbon steel. This steel is known for its ability to withstand high stress. However, not all high-carbon steel screws are equal. The coating on these screws plays a significant role too. Many options may flake or rust over time, reducing their effectiveness.

Another popular material is stainless steel. It offers excellent resistance to corrosion. Yet, it can be more expensive and sometimes less available. A recent consideration is the combination of coatings. Some black wood screws come with a layer of zinc followed by a black oxide coating. This combination can enhance durability. But careful inspection is required to ensure quality.

In practical use, the choice of material also depends on the project. For outdoor applications, stainless steel may be essential. For indoor furniture, coated high-carbon steel might suffice. Mistakes happen when one assumes that all black wood screws operate the same way. It’s vital to choose wisely based on your specific needs. Doing so can save time and resources in the long run.

When choosing black wood screws, several factors come into play. First, consider the material. Stainless steel and coated screws are common options. They resist rust and corrosion well. This is essential for outdoor projects. However, these screws may be pricier.

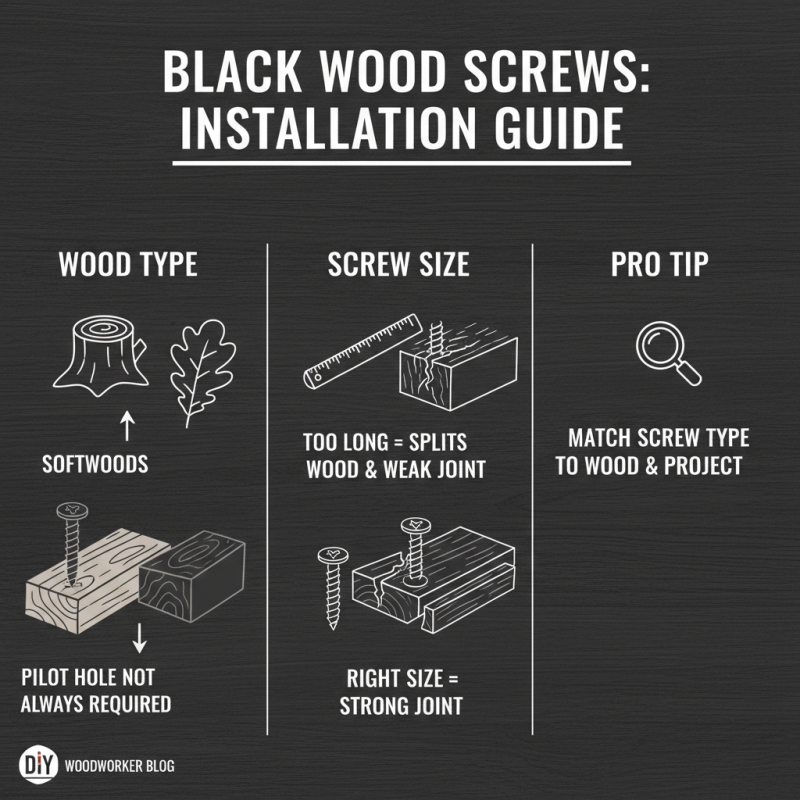

Next, look at the screw's length and diameter. A longer screw provides more grip, but it might split the wood. Choosing the right size can be tricky. Also, don't ignore the thread type. Coarse threads work best in softwoods, while fine threads suit hardwoods. Testing different types can lead to unexpected results.

Lastly, think about the head type. Flat heads sit flush, while pan heads can be more visible. You might want to balance aesthetics and function. Although there are many choices, each has its pros and cons. Keeping track of your preferences can help improve future projects. Remember, reflection on your choices can lead to better outcomes next time.

In 2026, the market for black wood screws is set to expand significantly. The demand for durable, high-quality fasteners in woodworking projects continues to rise. According to a recent industry report, the black screw segment is expected to grow by 15% annually through 2026.

When evaluating top brands of black wood screws, durability stands as a major concern. Consumers often seek screws that resist rust and can hold heavy loads. However, some products fall short in this area. It's essential to analyze performance reports from independent testing labs. These reports indicate that not all black finishes provide the same level of protection against corrosion.

In addition to performance, the ease of installation matters. Screws that require pre-drilling save time and effort, but some brands might strip easily. Users have reported mixed experiences regarding the user-friendliness of various brands. Ensuring a good grip on wood surfaces is crucial. As more woodworkers invest in these fasteners, addressing these issues will be key. The future market will require continual reflections on quality and reliability in this category.

When installing black wood screws, attention to detail is essential. The type of wood matters. Softwoods and hardwoods require different approaches. Always choose the right size of screw. A screw that's too long can split the wood and create a weak joint.

One important tip is to drill pilot holes. This prevents splitting and ensures a snug fit. The pilot hole should be slightly smaller than the screw’s diameter. Consider the material. If using a hardwood, a deeper pilot hole may help. Remember, miscalculated holes can lead to frustration.

Another aspect to keep in mind is the torque applied. Over-tightening can strip the screw or damage the wood. It’s easy to get carried away during installation. Take a moment to assess your progress. If you notice any cracks, reassess your technique. It’s better to pause and reflect than to end up with unsightly damage.