In the world of construction and manufacturing, the use of Weld Studs has transformed various processes. Expert Mike Johnson, a renowned engineer in the field, states, "Weld Studs enhance strength and efficiency in any project." This statement captures the heart of their significance.

Weld Studs offer numerous advantages, driving productivity and structural integrity. They are versatile, allowing for secure attachments on diverse materials like steel and concrete. Their ease of application reduces labor costs and speeds up the construction timeline. However, it's essential to choose the right type and size for specific applications. Sometimes, teams overlook this detail, leading to potential setbacks.

Additionally, while Weld Studs provide robust connections, the welding process must be handled with care. Improper techniques can compromise the desired outcomes. Thus, continuous training is vital for staff working with Weld Studs. In this ever-evolving industry, staying updated on techniques and technologies is crucial for maximizing benefits.

Weld studs provide significant benefits in construction and manufacturing. They enhance structural integrity by creating strong, secure connections. These connections reduce the risk of structural failures. The result is a reliable foundation for buildings and industrial equipment.

Using weld studs allows for better load distribution. This is crucial in heavy-duty applications. When stress is applied, weld studs hold materials firmly together. This minimizes the likelihood of joint failure under pressure. The robustness of welded connections often leads to longer-lasting structures.

Yet, challenges remain. Proper training in welding techniques is essential. Poorly executed welds can compromise structural integrity. Regular inspections are necessary to ensure these connections remain sound. Addressing these concerns will lead to a safer working environment and stronger designs.

Weld studs are increasingly popular in construction due to their

cost-effectiveness. They provide strong and reliable connections, reducing the need for additional fasteners.

According to a report by the Metal Construction Association, using weld studs

can lower labor costs by up to 30%. This is significant for any

construction project aiming to remain within budget.

Incorporating weld studs can reduce material waste. Researchers indicate that approximately

15% of construction materials are wasted due to improper fitting and excess cutting.

Weld studs minimize these issues. They allow quicker assembly, which saves both time and money. However,

it's crucial to consider initial training costs for workers. Investing in proper training can lead to greater long-term savings.

Despite their advantages, there are some concerns. For instance, if welds are not executed correctly,

it can compromise structural integrity. Quality control is essential.

Regular inspections are necessary to maintain safety standards. That said, when used properly,

the impact of weld studs on overall project costs can be remarkably positive.

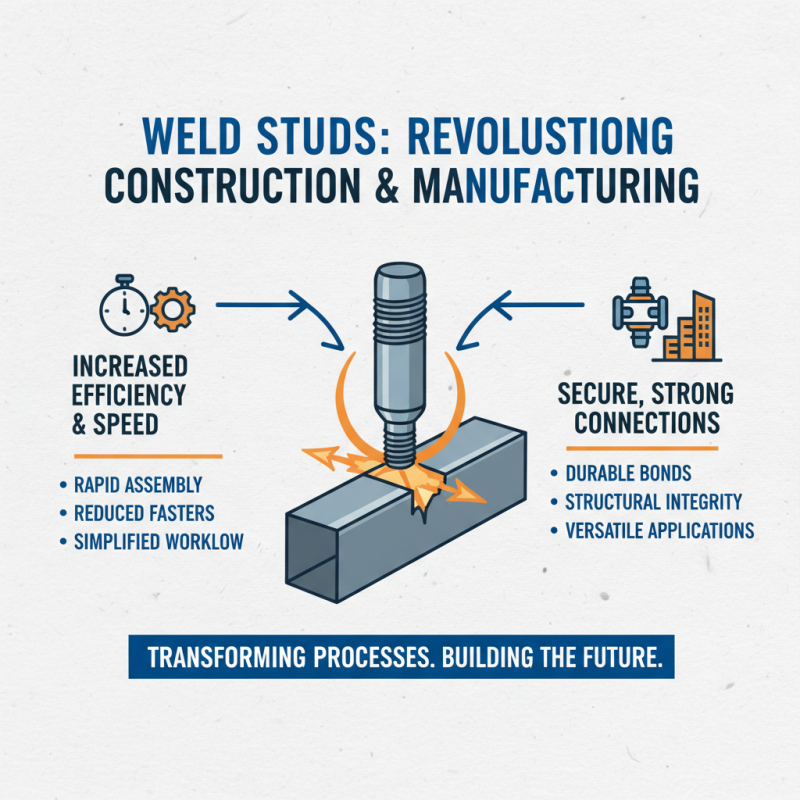

Weld studs are transforming construction and manufacturing processes. They enhance the efficiency and speed of assembly. By using weld studs, workers can create secure connections quickly. This reduces the need for additional fasteners and simplifies the workflow.

As you consider implementing weld studs, pay attention to the following tips. Ensure proper surface preparation before welding. A clean surface increases adhesion and reduces the risk of defects. Don’t rush the process; take the time to set up correctly. Skipping steps can lead to weak bonds.

Another point to consider is the training of your team. Familiarize them with the equipment. Adequate training minimizes mistakes and boosts confidence. Reflect on your previous projects; did inefficiencies arise from a lack of skill? Address these areas for improvement. Weld studs can improve speed, but only if your team is well-prepared.

Weld studs offer remarkable versatility across various manufacturing applications. They provide a strong bond between different materials, making them ideal for metal-to-metal and metal-to-plastic connections. The simplicity of installation makes them a go-to choice for many projects. They can be applied in tight spaces where traditional fasteners might struggle. This versatility ensures that weld studs can fit numerous requirements, from automotive manufacturing to construction.

However, there are some challenges with using weld studs. For instance, surface preparation is crucial. If surfaces are not clean, bond strength can diminish significantly. Furthermore, the heat generated during welding can warp thinner materials. This might not be evident until the project is complete. Others have found that the application process requires skilled labor to avoid mistakes. These factors can lead to added costs and extended project timelines, requiring careful planning and execution. Despite these potential drawbacks, the benefits of weld studs remain evident across many industries.

This chart represents the top benefits of using weld studs in construction and manufacturing, showcasing their versatility across various applications.

Weld studs play a crucial role in construction and manufacturing. One significant advantage is the reduction of weight. Traditional fastening methods often add considerable weight to structures. By using weld studs, builders can achieve strong connections with minimal added bulk. This can lead to lighter structures overall, which is particularly beneficial for high-rise buildings or bridges.

Material usage is another area where weld studs shine. They require less material compared to other fastening methods. This not only saves resources but also cuts costs. In some cases, this reduction can be quite dramatic, helping to lower the environmental impact of construction projects. However, it's essential to ensure that the right sizes and types of studs are chosen for specific applications; a mismatch can compromise strength.

Yet, despite these advantages, weld studs are not without challenges. Installation requires precision and skill. Improper application could lead to failures or weaknesses in the structure. This aspect demands thorough training for workers. Reflecting on best practices during installation can help mitigate risks associated with using weld studs. The balance between efficiency and safety must be carefully managed.

| Benefit | Description | Impact on Weight Reduction | Impact on Material Usage |

|---|---|---|---|

| Improved Strength | Weld studs provide strong and durable joints. | Can reduce the need for thicker materials. | Decreases overall material costs. |

| Time Efficiency | Quick installation reduces labor time. | Less time spent equates to lighter assemblies. | Lower labor costs due to faster processes. |

| Reduced Weight | Lightweight components lead to overall reduced structure weight. | Significantly lowers weight of structural members. | Less raw material is needed for lighter designs. |

| Versatility | Suitable for diverse materials and applications. | Allows for innovative lightweight solutions. | Maximizes efficiency in material usage. |

| Cost-Effectiveness | Lower overall costs when optimized properly. | Lightweight products lower shipping expenses. | Reduced waste during production. |

| Durability | Long-lasting performance in harsh conditions. | Supports thinner, more durable designs. | Optimize material lifespan and usage. |

| Safety Improvements | Improves structural integrity and load capacity. | Allows for safer, lighter structures. | Minimizing the need for excessive materials. |

| Reduced Setup Time | Simplifies setup processes compared to traditional methods. | Lightweight setups reduce transport and handling efforts. | Efficiently use available materials and time. |

| Eco-Friendliness | Lower material waste contributes to a sustainable construction practice. | Promotes lightweight materials that consume less energy. | Minimal resource consumption overall. |

| Aesthetic Flexibility | Weld studs allow for sleek designs and finishes. | Lightweight designs can be more visually appealing. | Allows efficient use of advanced materials. |