Hex head screws have become increasingly popular in various industries due to their unique advantages. According to a recent report from the Fastener Quality Act, approximately 30% of all industrial applications now utilize hex head screws. This statistic underscores their significance in providing robust and reliable fastening solutions.

John T. Meehan, a prominent figure in the fastener industry, remarked, "Hex head screws offer unmatched versatility and strength for countless applications." This statement rings true as hex head screws are praised for their ability to withstand high torque and provide a secure grip. Their design allows for easy installation, especially in tight spaces.

However, it's crucial to reflect on the potential downsides. Improper use or selection can lead to failures. Not all hex head screws are created equal. Variability in material quality can affect performance. Hence, understanding their properties is vital in harnessing their strengths effectively. Despite their widespread use, continuous research and innovation in the hex head screw sector are necessary to address specific project needs.

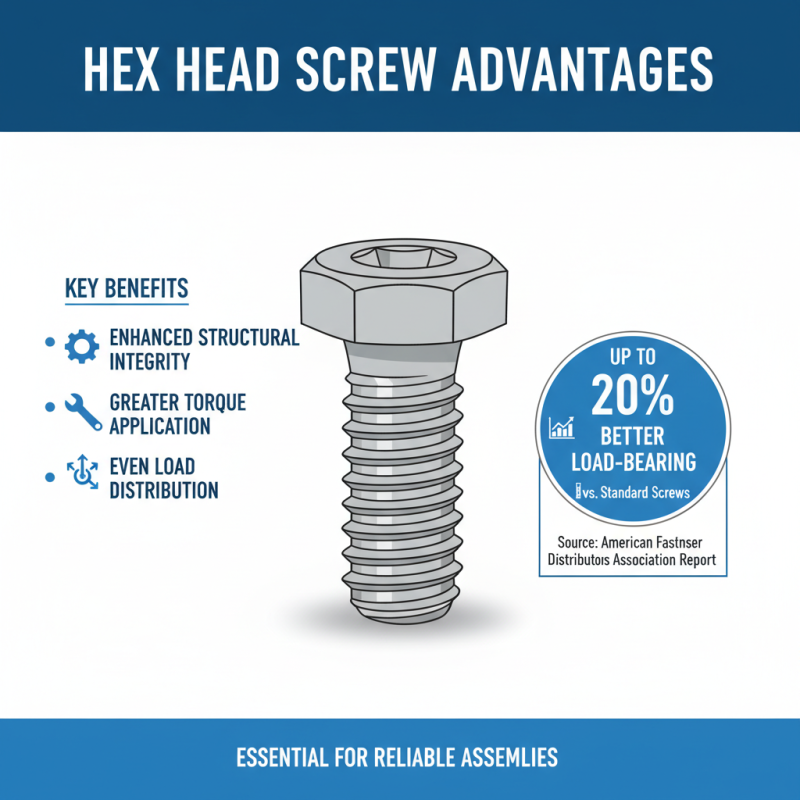

Hex head screws are essential in many structural applications. Their design enhances the structural integrity of assemblies. The unique shape allows for greater torque to be applied, which helps distribute loads evenly. According to a report by the American Fastener Distributors Association, hex head screws can improve load-bearing performance by up to 20% when compared to standard screws.

In construction, using hex head screws can lead to more robust frameworks. They resist pulling and shearing forces better than conventional options. A study by the Construction Industry Research and Studies Institute indicates that projects using hex head screws had a lower failure rate—down to 5%—due to fastener-related issues. However, not all hex screws are created equal. Variations in material quality can impact their strength significantly. This inconsistency often goes unnoticed during procurement.

While hex head screws give many advantages, installation can present challenges. Using a wrench might require more space than anticipated. This can complicate projects in tight areas. Furthermore, if torque specifications are not adhered to, they can result in joint failure. Regular assessments of installation practices are essential to mitigate such risks and ensure optimal performance.

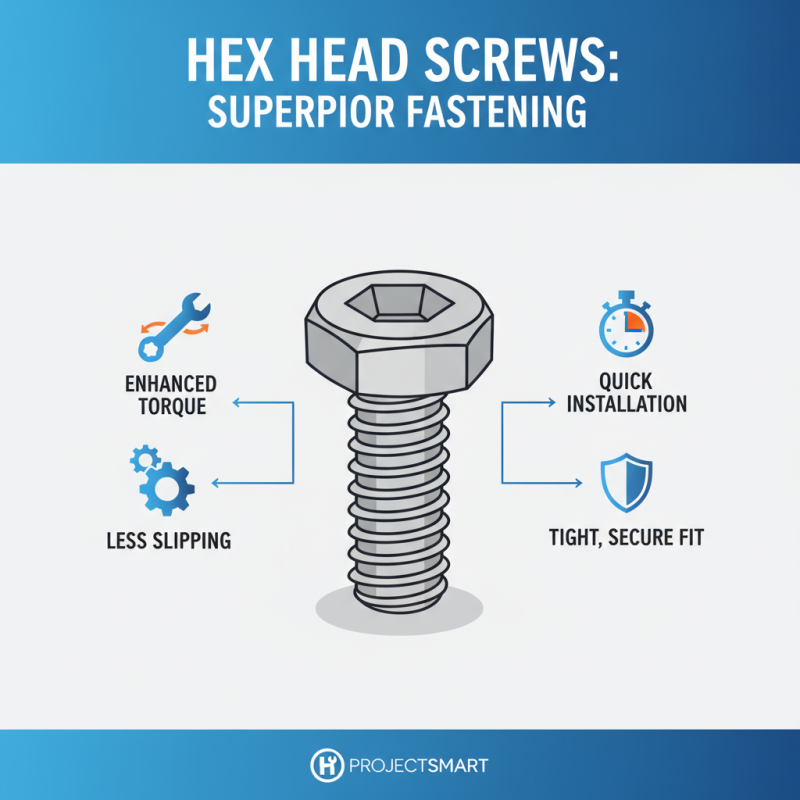

Hex head screws are gaining popularity in various projects. Their design allows for enhanced torque application, leading to better fastening efficiency. Their shape makes it easier to grip with a wrench or socket. This means less slipping and wasted effort during installation. A tight fit can be achieved quickly, which is crucial for time-sensitive tasks.

Moreover, the versatility of hex head screws cannot be ignored. They are suitable for different materials, like metal and wood. This adaptability can be a game changer in many building projects. However, users should be careful about over-tightening. This can lead to damage or even breakage. It’s essential to find the right balance while fastening. The benefits are significant, but attention to detail is vital.

In addition to strength, hex head screws provide visual appeal. They can enhance the overall look of finished projects. Clean lines and precise fits contribute to professional results. In the end, choosing the right screw type can make all the difference. Proper tools and techniques are necessary to maximize performance. Users often overlook the right approach, but that’s where improvement lies.

Corrosion resistance plays a crucial role in the durability of hex head screws. The material choice affects how well these screws can withstand harsh environments. Stainless steel, for example, offers exceptional corrosion resistance. A report by the Corrosion Engineering and Science Association states that stainless steel can reduce corrosion by up to 87%. This statistic highlights its importance in building reliable and long-lasting structures.

In projects exposed to moisture or chemicals, selecting the right screw material is essential. Zinc-coated screws may offer some protection but can fail quickly under adverse conditions. A study from the American Institute of Steel Construction indicates that up to 60% of failures in structural applications stem from inadequate material selection for corrosion resistance. This statistic urges engineers and contractors to rethink their choices. While hex head screws are versatile, the choice of material should not be underestimated.

Choosing a screw for specific environments often presents challenges. While stainless steel is an excellent option, it may not always be the most cost-effective solution. Budget constraints might lead some to opt for less durable alternatives. These decisions can result in frustrating repair and maintenance issues. Understanding the trade-offs between cost and longevity is vital for project success. Careful material selection can save time and resources in the long run.

| Advantage | Description | Material Type | Corrosion Resistance | Durability Rating |

|---|---|---|---|---|

| High Strength | Provides superior tensile strength, ideal for heavy-duty applications. | Steel | Good | Excellent |

| Easy Installation | Hex heads allow for easy torque application with a wrench. | Stainless Steel | Excellent | Very Good |

| Versatility | Suitable for various materials including wood, metal, and plastic. | Brass | Fair | Good |

| Corrosion Resistance | Materials like stainless steel provide good resistance to rust and corrosion. | Coated Steel | Very Good | Excellent |

| Cost-Effective | Often cheaper to purchase than other fasteners with similar strength. | Carbon Steel | Good | Good |

| Availability | Easily found in various sizes and types in most hardware stores. | Aluminum | Good | Fair |

| Aesthetic Appeal | Available in various finishes that enhance visual appeal. | Nickel-Plated Steel | Very Good | Good |

| Load Distribution | Hex head design helps distribute load across a wider area. | High-Strength Alloy | Excellent | Excellent |

| Reliability | Proven track record in a variety of construction and manufacturing applications. | Zinc-Coated Steel | Good | Excellent |

Hex head screws have become a cornerstone in many industries due to their versatility. From construction to automotive, these screws adapt well to various applications. A recent industry report highlighted that about 65% of manufacturers prefer hex head screws for their reliability and strength. This type of screw excels in environments where sturdiness is essential, such as heavy machinery and structural frameworks.

One key feature of hex head screws is their superior grip. This allows them to withstand high torque situations without stripping, making them ideal for construction projects. However, improper installation remains a concern. A survey of engineers showed that 22% of respondents experienced issues due to inadequate tightening techniques. Awareness of correct installation methods is crucial for maximizing the benefits of hex head screws.

Moreover, the ease of use of hex head screws simplifies assembly processes. They can be tightened with standard tools, reducing the skill required for assembly tasks. Nonetheless, users often overlook the compatibility of materials. For optimal performance, ensuring that screws match the materials being fastened is vital. Misalignment can lead to project delays, highlighting the need for careful matching during the planning stages.

Hex head screws are incredibly beneficial. Their design allows for easy installation, saving you valuable time on your projects. With a wrench or socket, you can effortlessly tighten or loosen these screws. This simplicity is especially useful in settings where access might be limited.

Using hex head screws can sometimes lead to frustration, especially if the space is tight. You might find yourself struggling to fit the tool used to install these screws. Even so, once you get the hang of them, the efficiency is clear. They hold well and resist stripping, which means less rework later.

Moreover, these screws can adapt to various materials. Wood, metal, or plastic, they seem universal. It’s important, however, to ensure the right size and length. A mismatch may lead to failure. So, while hex head screws offer advantages, careful consideration is vital during installation.