The Acme Threaded Rod is an essential component in various industries. Its unique design allows for efficient movement and stability in mechanical applications. According to the Machinery and Equipment Manufacturing report by IBISWorld, the demand for specialized fasteners has increased by 3.5% annually. This trend indicates a growing reliance on high-quality components like the Acme Threaded Rod.

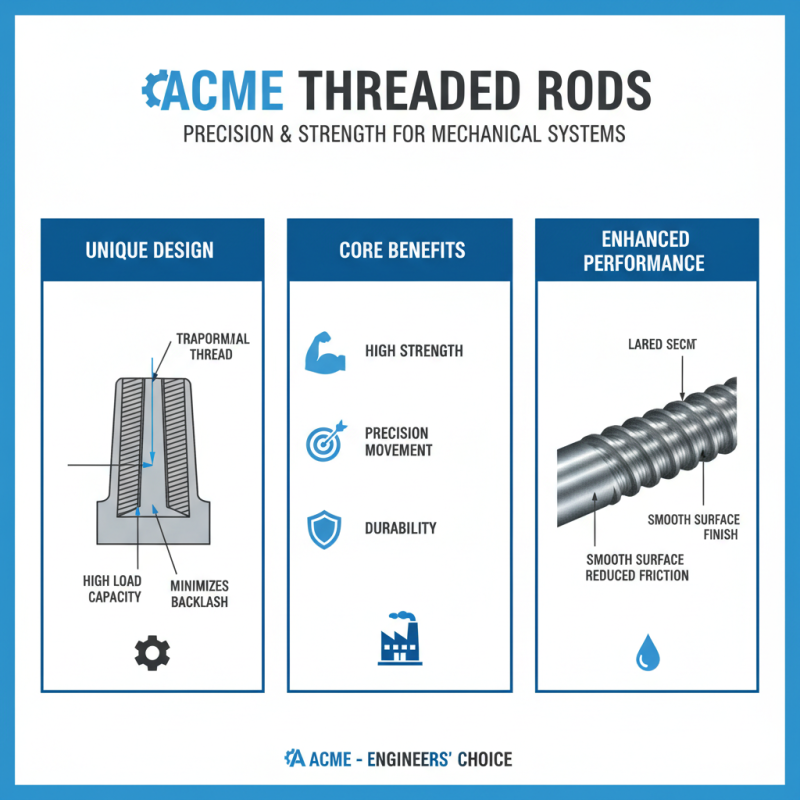

Typically, this rod is found in heavy machinery, construction, and automotive sectors. Its trapezoidal thread profile minimizes friction, resulting in smoother operation. Yet, manufacturers sometimes overlook the importance of precision in its production, leading to possible inefficiencies. While the Acme Threaded Rod is robust, its effectiveness relies heavily on quality control during fabrication.

In practical use, the Acme Threaded Rod can be paired with nuts and bearings to create powerful linear motion systems. It is crucial for engineers to understand its load-bearing capacities. However, improper installation or selection may result in mechanical failure. Ensuring correct specifications and tolerances is vital in maximizing its operational potential. This highlights the importance of meticulous design and application in modern engineering practices.

Acme threaded rods are essential components in many mechanical systems. They feature a unique trapezoidal thread design that provides high strength and load-bearing capacity. This design helps minimize backlash, making them ideal for applications requiring precision and mechanical movement. The surface finish of these rods also enhances their durability while reducing friction during operation.

One of the key characteristics of an Acme threaded rod is its ease of use. These rods can be easily machined to required lengths. However, the threading process can be challenging. Getting the right pitch is crucial. Acme rods are commonly used in lead screws, which are found in machinery and CNC tools. They convert rotary motion into linear motion effectively.

Despite their benefits, Acme threaded rods are not perfect. Incorrect installation can lead to issues like misalignment. Regular maintenance can help prevent wear and tear over time. Finding the right material for specific applications also requires careful consideration. Not everyone realizes the significance of these details until problems arise.

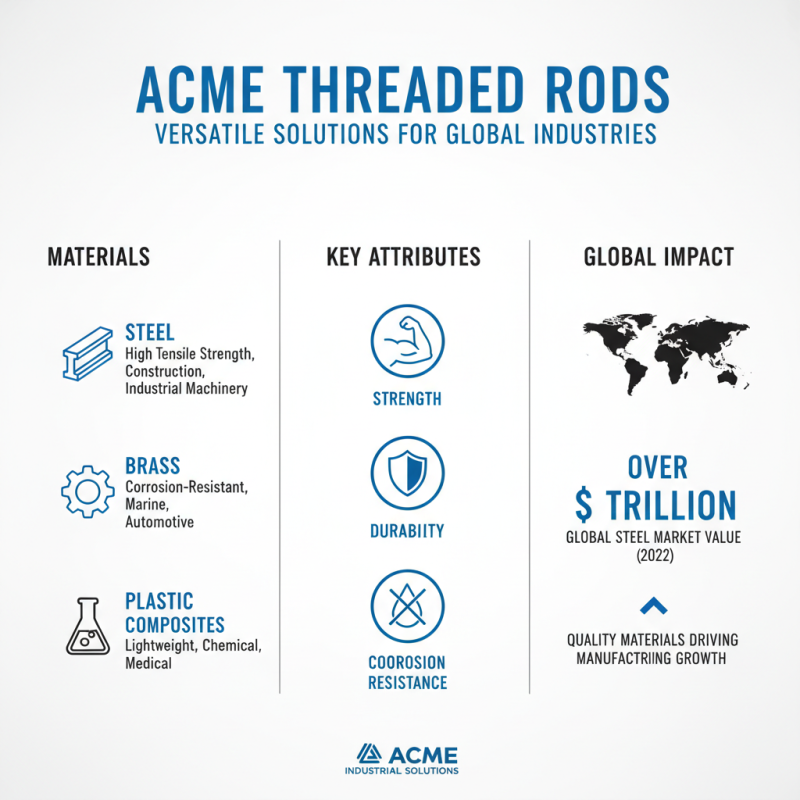

Acme threaded rods are widely used in various applications across many sectors. The rods are primarily made from steel, brass, and plastic composites. These materials are chosen for their strength, durability, and resistance to corrosion. For instance, steel rods are preferred in construction due to their high tensile strength. In fact, industry reports indicate that the global steel market was valued at over $1 trillion in 2022. This highlights the importance of quality materials in manufacturing.

Brass is another common material. It offers excellent resistance to corrosion and is often used in applications involving moisture. However, it's essential to note that while brass rods are sturdy, they can be prone to wear under heavy loads. Lastly, plastic composite rods are gaining popularity due to their lightweight nature. The composites can be tailored for specific applications, though they may not withstand heavy-duty tasks as well as metal counterparts.

Understanding these materials is crucial. Manufacturers need to assess the specific needs of each project. Choosing the right material impacts durability and overall performance. Sometimes, innovations in materials lead to unexpected challenges. Companies must grapple with balancing cost, strength, and functionality.

Acme threaded rods are widely used in various industries due to their unique design. They have a trapezoidal thread profile, which provides better load distribution and stability. This makes them ideal for applications where precision and strength are crucial. Construction companies often utilize these rods as lifting mechanisms. They ensure heavy materials are safely raised or lowered.

In the manufacturing sector, acme threaded rods are essential for machinery assembly. They facilitate smooth movement in linear guides. Additionally, the automotive industry uses them in adjustable suspension systems. Here, they provide adjustable height features for vehicles, enhancing performance. Yet, challenges can emerge. If not properly maintained, these rods can wear out quickly, leading to malfunction.

In agriculture, acme threaded rods play a role in irrigation systems. They adjust the height of pipes and ensure efficient water flow. However, exposure to the elements can compromise their integrity. In such cases, regular inspection becomes crucial to maintain functionality. Each industry sees diverse applications, showcasing the versatility of these rods.

Acme threaded rods are gaining popularity in various industries for their unique advantages. Unlike standard fasteners, these rods feature a trapezoidal thread design. This design allows for greater load-bearing capacity. According to recent reports, Acme threaded rods can withstand forces up to 20% more than traditional options. This makes them ideal for applications in machinery and construction.

One key advantage is their efficiency in converting rotary motion to linear motion. This is crucial for applications such as lead screws and linear actuators. The smooth operation provided by the Acme thread design reduces wear and tear on moving parts. However, one must consider that the manufacturing process can sometimes lead to

tolerances that may not meet specific requirements. Inconsistent quality can arise if not properly managed.

Additionally, Acme threaded rods are generally more resistant to axial wear. This durability is linked to their larger contact area. Many engineers report a lower failure rate compared to standard screws. Yet, the rods can also come with higher upfront costs. It’s essential to weigh these costs against long-term savings from reduced maintenance and replacement needs. Balancing these factors is key for making informed decisions.

Acme threaded rods are crucial in many applications. Their design allows for efficient load transfer. They usually come in various sizes, making them versatile for different projects. The pitch of the threads can affect performance significantly. A coarser thread may handle heavier loads but might turn harder.

Common sizes for Acme threaded rods typically range from ¼ inch to 2 inches in diameter. Thread specifications often include specific pitch measurements. For instance, a ½ inch rod might have a pitch of 10 threads per inch. The right size and thread can impact how effectively the rod functions in a mechanical assembly. Users often make the mistake of miscalculating required dimensions.

The choice of material for these rods can also play a role in their performance. Steel, stainless steel, and nylon are popular options. Each material comes with advantages and drawbacks. For instance, steel offers strength but may corrode. Nylon can provide good resistance to chemicals but lacks high load-bearing capacity. Reflecting on these factors is essential for optimal usage.

| Rod Size | Thread Pitch (inches) | Diameter (inches) | Material | Typical Applications |

|---|---|---|---|---|

| 1/4" | 0.2 | 0.250 | Steel | Small machinery, fixture assembly |

| 3/8" | 0.3 | 0.375 | Stainless Steel | Automotive, HVAC systems |

| 1/2" | 0.4 | 0.500 | Aluminum | Construction, structural supports |

| 5/8" | 0.5 | 0.625 | Carbon Steel | Heavy-duty machinery, industrial equipment |

| 3/4" | 0.6 | 0.750 | Brass | Electrical components, lighting fixtures |