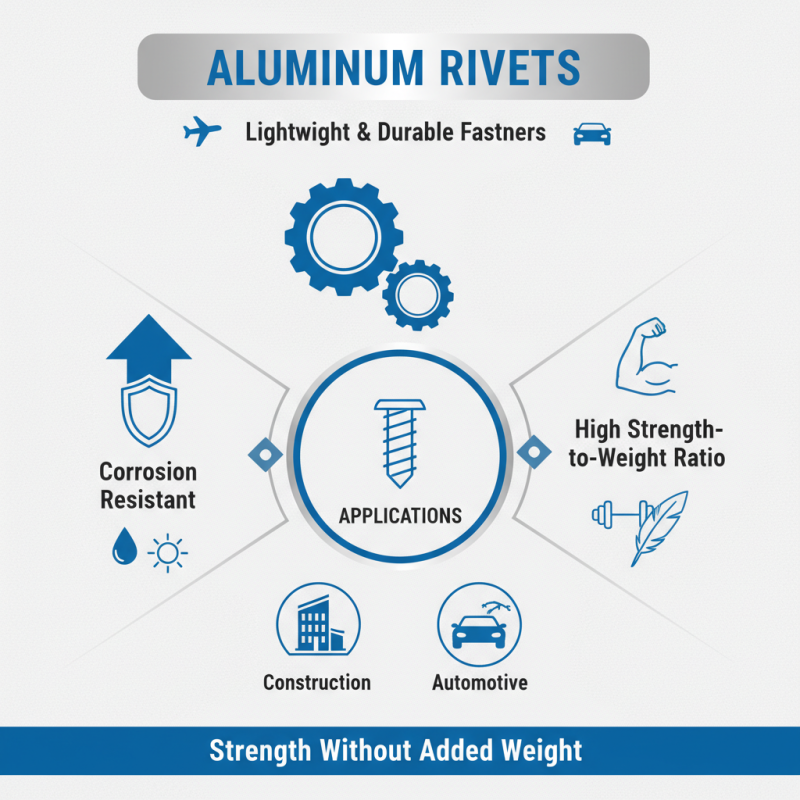

In the world of construction and manufacturing, aluminum rivets hold a vital role. These fasteners are lightweight yet durable, making them a popular choice for various applications. Understanding the features and types of aluminum rivets is crucial for the success of your project.

Aluminum rivets come in different shapes and sizes. Selecting the right one can be challenging, especially for beginners. Many people overlook the importance of rivet specifications, leading to issues down the line. Common problems include reduced strength and improper joining, which can be costly to fix.

Exploring the best aluminum rivets in 2026 requires a look at top manufacturers. Checking reviews and performance metrics can provide insights. However, what works for one project might not suit another. Reflecting on your application needs is key to making the right choice and avoiding common pitfalls.

Aluminum rivets are essential fasteners in various industries. They are lightweight and offer excellent resistance to corrosion. This makes them ideal for applications in automotive, aerospace, and construction. Their ability to withstand harsh conditions makes them a preferred choice for many engineers.

Common uses of aluminum rivets include securing aircraft panels and building frameworks. In automotive manufacturing, they are used to attach body panels. The lightweight nature of aluminum helps improve fuel efficiency in vehicles. However, not all projects require aluminum rivets. Sometimes, they may not provide the required strength in heavy-duty applications, leading to potential failures.

When choosing aluminum rivets, consider factors like size and type. Knowing the specific requirements of your project is crucial. It’s easy to overlook these details, leading to mismatched rivets. In certain cases, using the wrong rivet can compromise the integrity of the entire structure. Just remember, every fastener counts in ensuring safety and durability.

| Rivet Type | Head Style | Diameter (mm) | Length (mm) | Material Grade | Common Uses |

|---|---|---|---|---|---|

| Structural Rivets | Countersunk | 4.0 | 10 | 6061-T6 | Aircraft assembly, automotive |

| Blind Rivets | Dome | 3.2 | 8 | 5052-H32 | Sheet metal fabrication, woodworking |

| Solid Rivets | Round | 5.0 | 12 | 2024-T351 | Construction, heavy machinery |

| Multi-Grip Rivets | Flat | 4.8 | 10 | 6063-T5 | General assembly applications |

| Specialty Rivets | Sealed | 6.4 | 15 | 7075-T6 | Aerospace, marine applications |

When it comes to aluminum rivets, variety is key. There are several types available, each serving a specific purpose. Blind rivets are the most common. They allow for fastening from one side only, making them user-friendly in tight spaces. The setting process is straightforward, even for beginners. However, beginners might struggle with aligning them perfectly.

Solid aluminum rivets are another option. They are known for their strength and durability. Unlike blind rivets, they require access from both sides of the material. This might be a drawback for some applications. Still, they offer an unparalleled grip and resistance to shear forces.

There are also semi-tubular rivets. These rivets have a partial hole, allowing for expansion during installation. They can provide a good balance of strength and ease of use. However, choosing the right type can be challenging. Each project has unique requirements. Proper understanding of these types ensures you select the best rivet for your needs.

Aluminum rivets are lightweight yet durable fasteners. They are widely used in various industries, particularly in construction and automotive applications. Their resistance to corrosion makes them suitable for outdoor use. When you choose aluminum rivets, you're opting for strength without added weight.

One of the key benefits is their ease of installation. They can be quickly applied using simple tools. This saves time during assembly. Additionally, aluminum rivets provide a tight bond, ensuring materials stay securely joined. However, improper installation can lead to joint failure. It's crucial to follow best practices to avoid this.

Another noteworthy feature is their versatility. Aluminum rivets can be used on different materials, from metals to plastics. This adaptability is appealing, but it’s essential to assess compatibility before use. Considering factors like environmental conditions is necessary. Sometimes, a rivet’s strength can be overestimated, leading to potential issues. Testing in real-world conditions is wise to ensure reliability.

When choosing aluminum rivets, several factors are essential. The size and diameter of the rivet significantly affect its performance. A rivet that is too small may not hold materials securely. Conversely, a rivet that is too large can cause material distortion. Consider the thickness of the materials you'll be joining. This factor greatly influences the rivet’s ability to provide strength.

Additionally, the environment where the rivets will be used plays a key role. Will they be exposed to high moisture or chemicals? Corrosion resistance becomes critical in such scenarios. Some rivets may perform poorly in these conditions, which can be a costly mistake. You might find yourself reflecting on your choices if the rivets fail prematurely.

Lastly, take into account the installation process. Some rivets require special tools or techniques, which can complicate things. If you're new to riveting, this could lead to errors. It is worth noting that learning curves exist with different types of rivets. Ultimately, the right choice can save time and resources while enhancing the durability of your projects.

When it comes to aluminum rivets, proper installation is key to ensuring strength and durability. Start by selecting the right size rivet for your project. It's often a mistake to choose a rivet that's either too big or too small. This can lead to structural weakness. Measure twice, and cut once—this old saying holds true for rivets as well.

Ensure your materials are clean and free of debris. If the surface is not prepared well, the rivet might not adhere properly. This can create unexpected failures later. Use a drill to create precise holes. Avoid using excessive force, as it can lead to irregular holes. Try to maintain a steady hand throughout the drilling process.

Don’t forget to wear protective gear. Safety is essential, but people sometimes overlook it. When using a rivet gun, ensure you have the correct pressure settings. An over-pressured rivet can exacerbate the problem. Remember to check for any signs of misalignment once installed. A small miscalculation can lead to significant issues down the line. Always keep learning from each project to refine your technique.